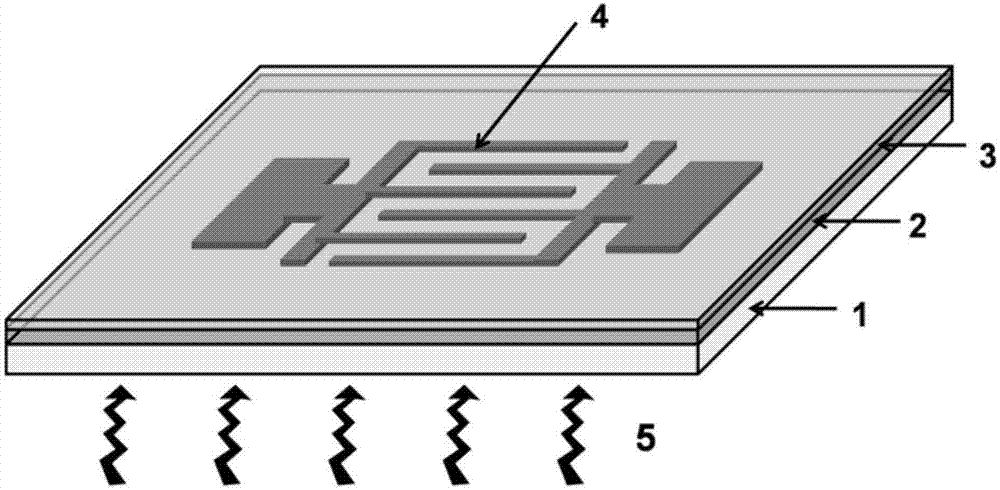

Precious-metal doped TiO2/TiO2 homogeneous-structure ultraviolet detector and preparation method

A UV detector, homogenous structure technology, used in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as photoelectric performance limitations of UV detectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

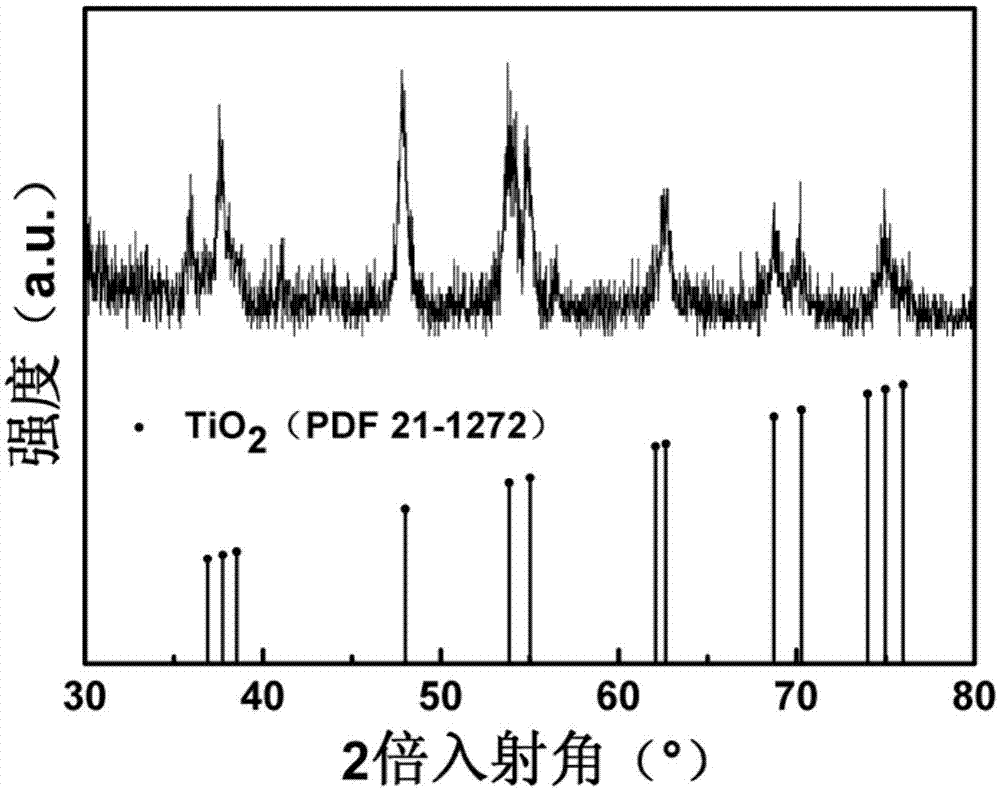

Embodiment 1

[0036] [1] At room temperature, drop 8mL of acetic acid, 8mL of acetylacetone, and 8mL of deionized water in sequence into a mixture of 8mL of tetrabutyl titanate and 90mL of ethanol that is constantly stirred and mixed evenly, and continue to stir until a uniform and transparent orange-red color is obtained. sol, TiO was obtained after aging for 36 hours 2 Sol;

[0037] [2] Put the quartz substrate into acetone, ethanol and deionized water in turn, ultrasonic for 12 minutes respectively, the ultrasonic power is 90W, and then blow dry under nitrogen flow;

[0038] [3] Spin-coat 6 layers of TiO on the cleaned quartz substrate with a homogenizer 2 Sol, the rotation speed of each layer is 2500rpm, the coating time is 15s, after coating, it is baked at 120°C for 6 minutes, and cooled in the air for 3 minutes; finally, the spin-coated TiO 2 The substrate of the sol is placed in a muffle furnace and sintered at 600°C for 2 hours to form anatase TiO 2 Thin film with a thickness of...

Embodiment 2

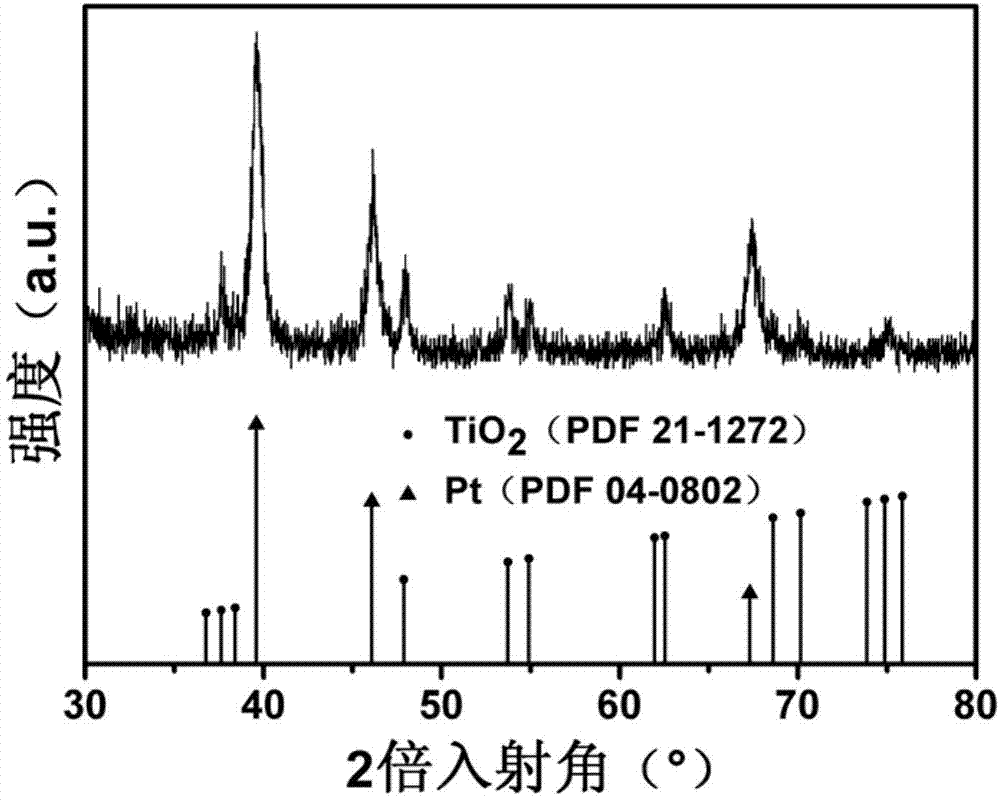

[0041] [1] At room temperature, drop 8mL of acetic acid, 8mL of acetylacetone, and 8mL of deionized water in sequence into a mixture of 8mL of tetrabutyl titanate and 90mL of ethanol that is constantly stirred and mixed evenly, and continue to stir until a uniform and transparent orange-red color is obtained. sol, TiO was obtained after aging for 36 hours 2 Sol;

[0042] [2] Take 0.2g of chloroplatinic acid (H 2 PtCl 6 6H 2 0), it is added in the mixed solution of 5mL water and 5mL ethanol, stirs until fully dissolving, the mixed solution after dissolving is added the TiO of 10mL that takes out from step [1] 2 In the sol, heat and stir in a water bath at 80°C for 3 hours to obtain Pt / TiO 2 Sol;

[0043] [3] Put the quartz substrate into acetone, ethanol and deionized water in turn, ultrasonic for 12 minutes respectively, the ultrasonic power is 90W, and then blow dry under nitrogen flow;

[0044] [4] Spin-coat 6 layers of Pt / TiO on the cleaned quartz substrate with a coa...

Embodiment 3

[0047] [1] At room temperature, drop 8mL of acetic acid, 8mL of acetylacetone, and 8mL of deionized water in sequence into a mixture of 8mL of tetrabutyl titanate and 90mL of ethanol that is constantly stirred and mixed evenly, and continue to stir until a uniform and transparent orange-red color is obtained. sol, TiO was obtained after aging for 36 hours 2 Sol;

[0048] [2] Take 0.2g of chloroplatinic acid (H 2 PtCl 6 6H 2 0), it is added in the mixed solution of 5mL water and 5mL ethanol, stirs until fully dissolving, the mixed solution after dissolving is added the TiO of 10mL that takes out from step [1] 2 In the sol, heat and stir in a water bath at 80°C for 3 hours to obtain Pt / TiO 2 Sol;

[0049] [3] Put the quartz substrate into acetone, ethanol and deionized water in turn, ultrasonic for 12 minutes respectively, the ultrasonic power is 90W, and then blow dry under nitrogen flow;

[0050] [4] Spin-coat 5 layers of Pt / TiO on the cleaned quartz substrate with a coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com