Large-power pulse air-flow chemical laser apparatus

A pulsed airflow, chemical laser technology, applied in lasers, laser parts, electrical components, etc., can solve the problem of difficult high repetition frequency, large volume uniform glow discharge and light irradiation, difficult to obtain high energy, high repetition rate pulsed laser output, reduce the average power of the output laser, etc., to achieve the effect of excellent beam quality, deep modulation depth, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

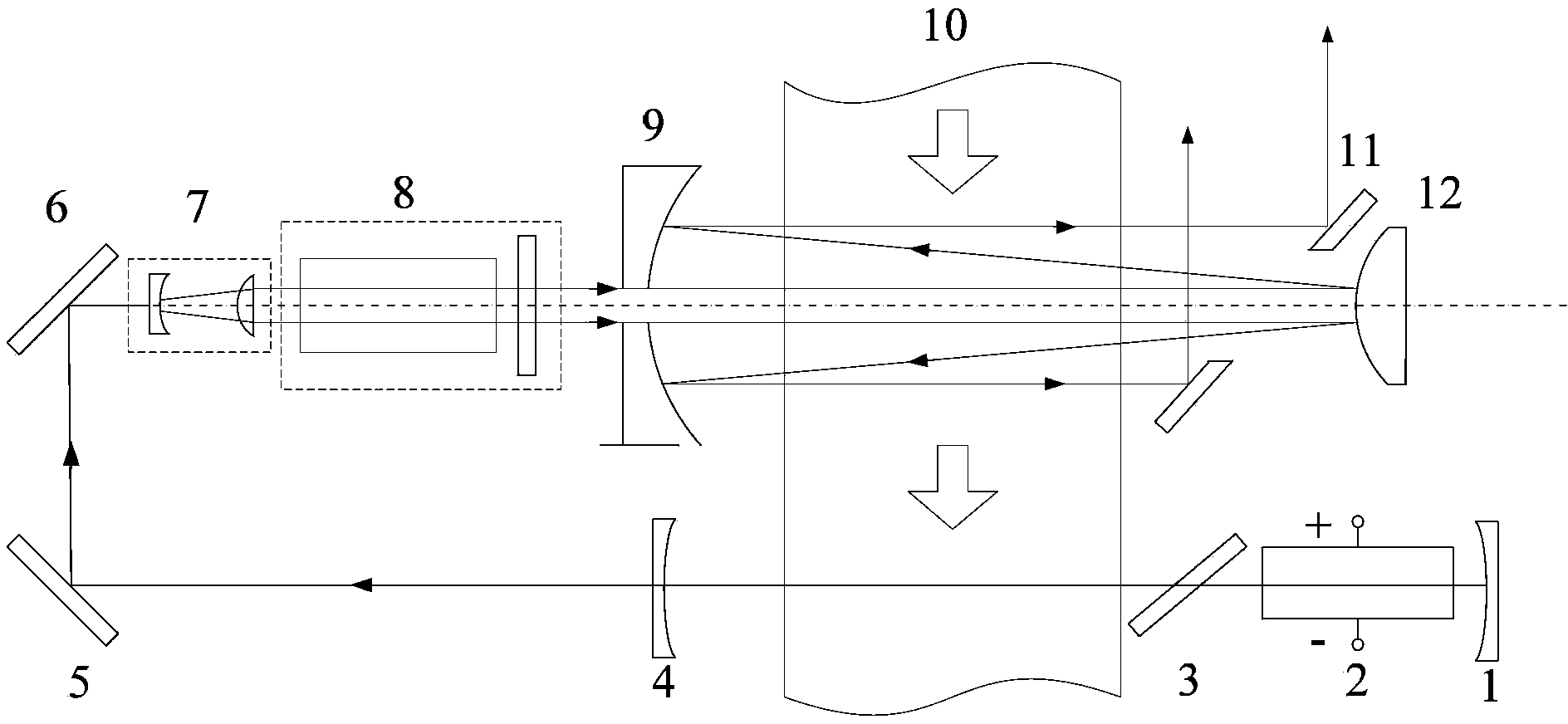

[0020] As shown in the accompanying drawings, the structure of the pulsed oxygen iodine chemical laser of the present invention comprises:

[0021] A high-power pulsed gas flow chemical laser device, including a laser oscillator and a laser amplifier,

[0022] The laser amplifier consists of a plano-concave rear cavity mirror 9, a scraper mirror 11, a plano-convex front cavity mirror 12, and an active medium gain region 10 located on the optical path between the plano-concave rear cavity mirror 9 and the scraper mirror 11. ;

[0023] The laser oscillator includes a coaxial plano-concave mirror 1 and a plano-concave output coupling mirror 4, which are sequentially arranged between the plano-concave mirror 1 and the plano-concave output coupling mirror 4, an electro-optic Q-switching crystal 2, and a polarizer 3; The concave mirror 1 , the electro-optic Q-switching crystal 2 , the polarizer 3 , and the plano-concave output coupling mirror 4 are on the same optical axis; the opt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com