Preparation method of biological glass mat and application of biological glass mat

A bio-glass, biological technology, applied in medical science, bandages, absorbent pads, etc., can solve the problem of no antibacterial properties, and achieve the effects of reducing pain, preventing wound infection, and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

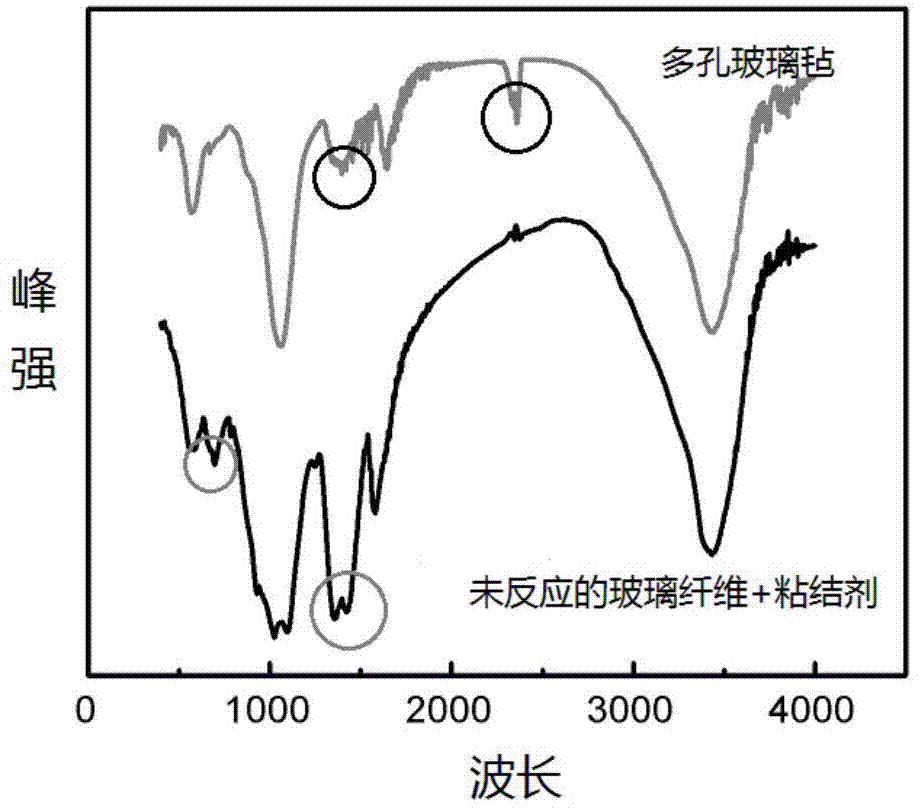

Image

Examples

Embodiment 1

[0050] 1) Preparation of borate bioglass fiber by blowing method:

[0051] According to the composition of the borate bioglass in Table 1, the oxides, chlorides, carbonates, sulfates and phosphates corresponding to the metal oxides were weighed as glass batch materials. The purity of the raw materials was analytically pure. After grinding, fully Mix to get the original ingredients. Put the original ingredients in a platinum crucible and melt them in a silicon-molybdenum furnace at 1050°C for 0.5h. In the molten state, after the molten glass flows out, use 25°C cold air with an air pressure of 2.0MPa. Blowing, blowing the molten glass into fibers (glass wool) in the state of cotton wool, with a diameter of 50 nanometers to 2 microns, and collecting them for later use.

[0052] Table 1

[0053]

[0054] 2) Preparation of modified chitosan liquid phase:

[0055] Prepare the modified chitosan liquid phase with the following mass percentages of components: 2% acetic acid, 1%...

Embodiment 2

[0060] 1) Preparation of borate bioglass fiber by plugging method

[0061] According to the composition of the borate bioglass in Table 2, the oxides, chlorides, carbonates, sulfates and phosphates corresponding to the metal oxides were weighed as glass batch materials. The purity of the raw materials was analytically pure. After grinding, fully Mix to get the original ingredients. Put the original ingredients in a platinum crucible, melt in a silicon-molybdenum furnace at 1200°C for 4 hours, and flow the molten glass into a platinum crucible with a leaky plate (the hole diameter of the leaky plate is 0.5mm) at the bottom. The glass liquid flows down from the hole of the leak plate to form a glass rod. When it is not completely cooled, it is drawn into a glass filament with a diameter of 30-50 microns by using a wire drawing device (the linear speed of the wire drawing machine is 0.5m / s). Then cut into short fibers (25-30 mm in length) for later use.

[0062] Table 2

[00...

Embodiment 3

[0070] 1) Preparation of borate bioglass fiber by plugging plate method:

[0071] According to the borate bioglass composition of table 3, take by weighing oxide compound, chloride, carbonate, sulfate and phosphate corresponding to metal oxide as glass batch material, the purity of raw material is analytical pure, after grinding, fully Mix to get the original ingredients. Put the original ingredients in a platinum crucible, melt in a silicon-molybdenum furnace at 1250°C for 4 hours, and flow the molten glass into a platinum crucible with a drain plate (the hole diameter of the leak plate is 0.5mm) at the bottom. The glass liquid flows down from the hole of the leak plate to form a glass rod. When it is not completely cooled, it is drawn into a glass filament with a diameter of 10-20 microns by using a wire drawing device (the linear speed of the wire drawing machine is 10m / s). Cut into short fibers (25-30 mm in length) for later use.

[0072] table 3

[0073]

[0074] 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com