Technology and system for processing wastewater generated during brown coal upgrading process

A technology for treating process and waste water, applied in multi-stage water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve unfavorable long-distance transportation and storage of lignite raw coal and large greenhouse gas emissions , Difficulty in large-scale development and utilization, etc., to achieve the effect of low operating cost, short project cycle, and obvious treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

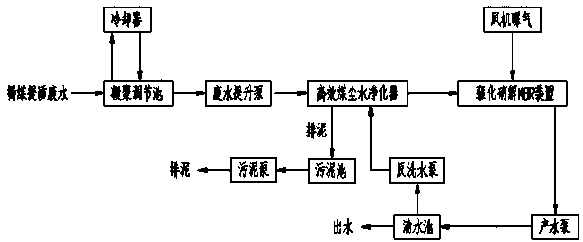

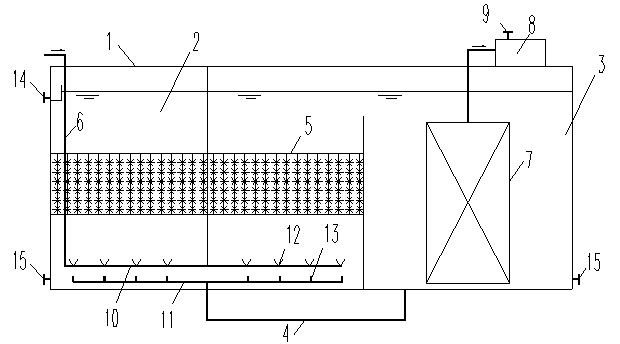

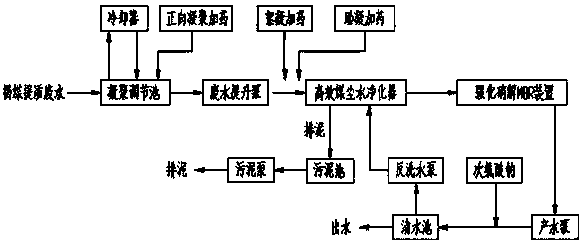

[0038] like figure 1 As shown, a lignite wastewater treatment system consists of a coagulation regulating tank, a cooler, a wastewater lift pump, a high-efficiency coal dust water purifier, an enhanced nitrification MBR device, a clear water tank and a sludge tank. The water outlet is connected to the water inlet of the high-efficiency coal dust water purifier through the waste water lifting pump, the water outlet of the high-efficiency coal dust water purifier is connected to the water inlet of the enhanced nitrification MBR device, and the water outlet of the enhanced nitrification MBR device is connected to the inlet of the clean water pool through the water production pump. The sludge outlet of the dust water purifier is connected to the inlet of the sludge tank, and the cooler is connected to the coagulation regulating tank to cool the wastewater in the coagulation regulating tank; the high-efficiency coal dust water purifier is equipped with a cyclone and an intermediate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com