Preparation method of anti-seepage water delivery tank of channel

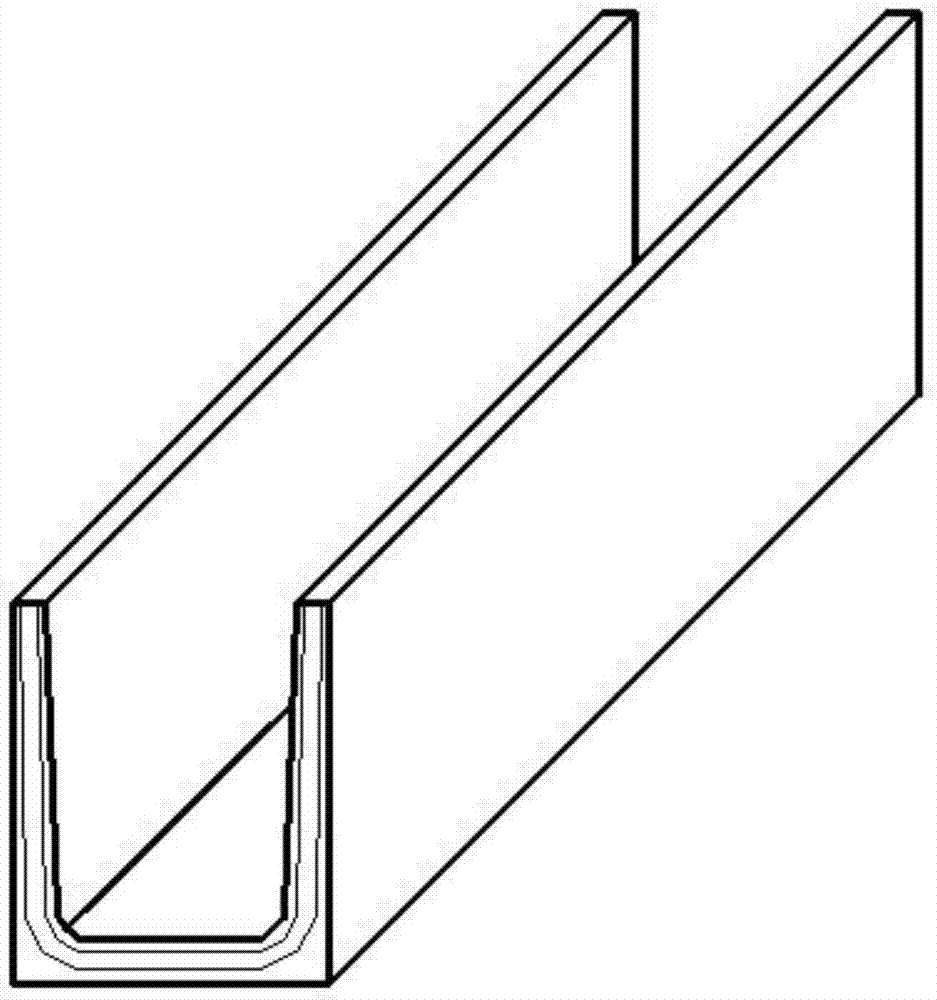

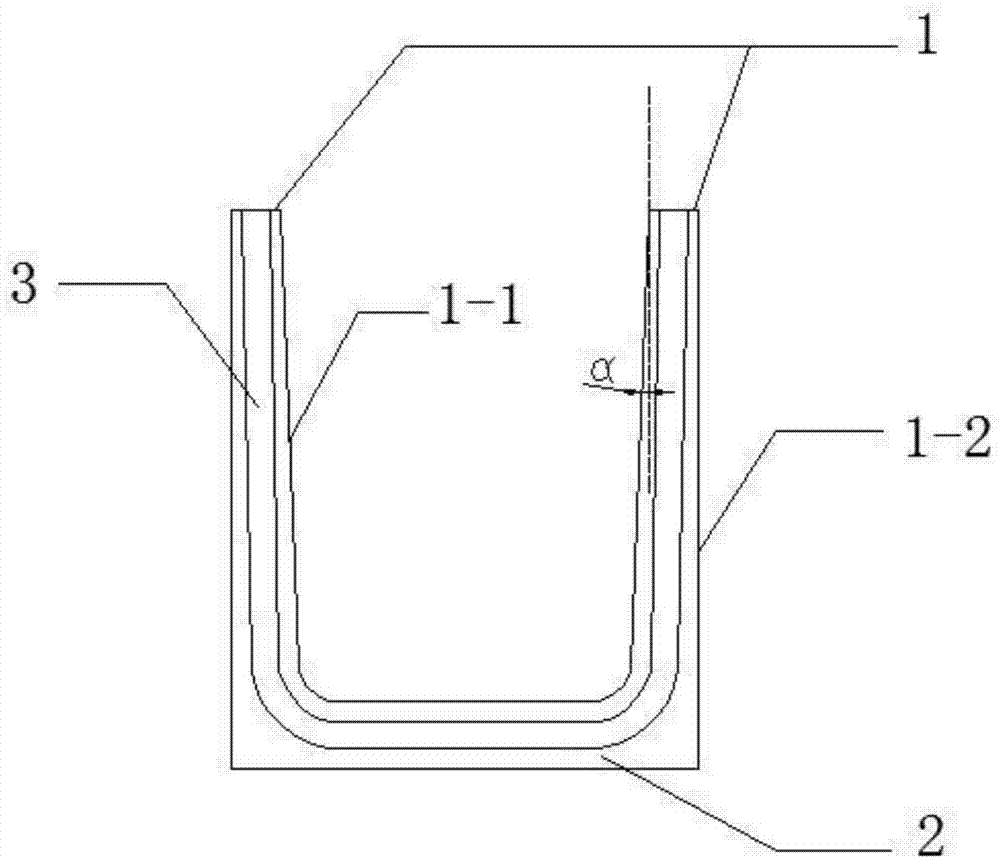

A water tank and channel technology is applied in the field of preparation of U (rectangular) water tanks for water conservancy and water conveyance in farmland. Smooth, uniform quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific implementation mode one: the preparation method of the anti-seepage water delivery tank of the channel in this implementation mode is implemented according to the following steps:

[0015] 1. Weigh 390-420kg of cement, 70-80kg of fly ash, 25-30kg of mineral powder, 178-198kg of water, 600-720kg of medium sand, 677-718kg of gravel with specifications 1-2, 400-450kg of crushed stone with a specification of 0.5, 5-8kg of steel fiber and 9.5-10.5kg of admixture are used as raw materials;

[0016] 2. Add the weighed raw materials to the mixer, stir them evenly, and then transfer them to the distribution machine through the feeding truck. In the water tank mould, at the same time, the vibrating table drives the anti-seepage water delivery tank mold to vibrate at a frequency of 1000-1500 Hz for 2-3 minutes to complete the cloth vibration molding of concrete raw materials;

[0017] 3. Transport the mold of the anti-seepage water delivery tank carrying the vibration-fo...

specific Embodiment approach 2

[0021] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the label of the cement described in step one is 425. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the grade of the fly ash described in step 1 is the first grade. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com