Thermoplastic elastomer composition capable of using in low temperature coated nylon and its preparation method

A thermoplastic elastomer and composition technology, which is applied to the thermoplastic elastomer composition of low temperature coated nylon and its preparation field, can solve the problem of low fluidity of elastomer products, general adhesion of coated nylon, and adhesion of coated nylon. Small and other problems, to achieve the effect of excellent processing performance, wide application range and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further elaborated below in conjunction with specific embodiments. However, these examples are for illustrative purposes only, and are not intended to limit the protection scope of the present invention.

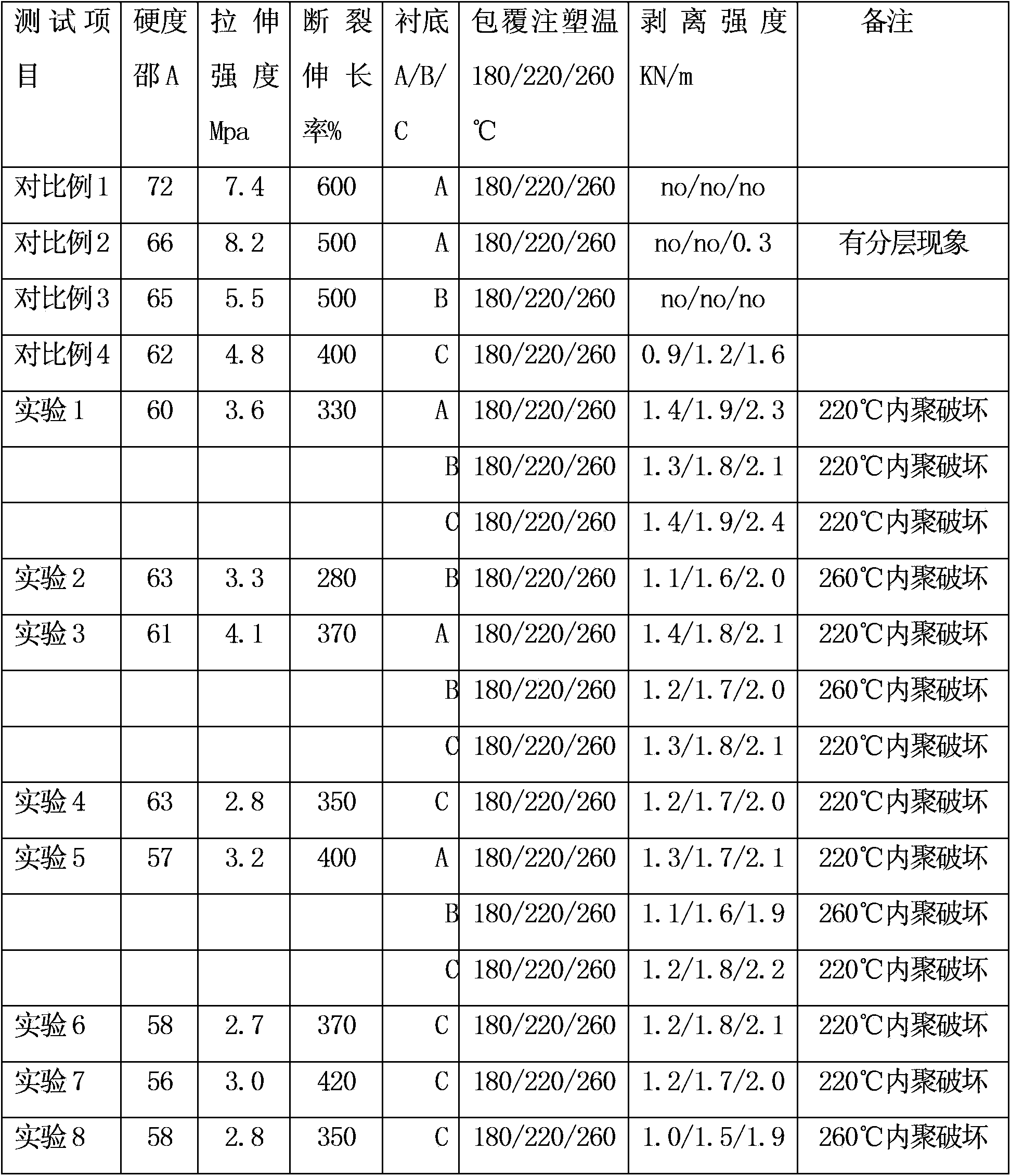

[0053] First mix the styrene-butadiene rubber-based thermoplastic elastomer and filler oil in a high-speed mixer, then add other materials into the mixer according to a certain ratio, and then mix them in the CTE35 twin-screw of Coperion Keya (Nanjing) Machinery Co., Ltd. Perform high-speed shear melt blending and granulation in the extruder, and perform secondary molding on the CJ80E injection molding machine of Guangdong Zhende Plastic Machinery Factory to coat nylon-based materials. The bonding and coating force is tested in accordance with GB / T2790 -1995 standard to test, hardness test according to ISO868 standard, tensile strength and elongation test to install ISO37 standard. The raw materials used in the experiment are as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com