Method for preparing furoic acid by cell catalysis of furfural

A technology for furfural and furoic acid, which is applied in the field of cell catalysis of furfural to prepare furoic acid, can solve the problems of furoic acid product separation or wastewater treatment difficulties, inability to fully meet usage requirements, consumption of metal catalysts, etc., and achieves good practicability and easy industrialization. , The effect of wastewater treatment is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In a 250mL Erlenmeyer flask with a stopper, add 50mL furfural aqueous solution, the initial concentration of furfural is 6.5g / L, add 10g / L calcium carbonate to control the pH of the reaction system from 4.0 to 7.0, and transfer the shaker flask to a constant temperature shaking culture at 30°C ± 5 bed, adjust the shaking and stirring speed to 220r / min, insert the activated Gluconobacter oxydans to a cell concentration of 1.0 g / L to carry out the cell catalytic reaction.

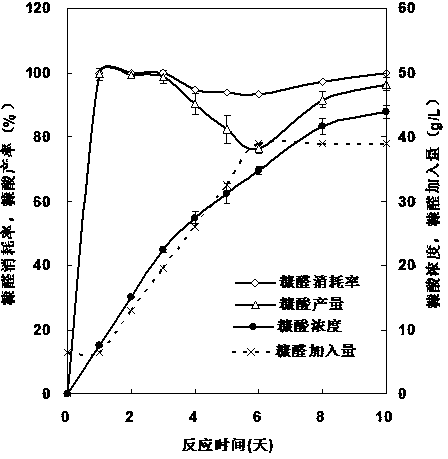

[0022] The operation method of semi-continuous addition was adopted, adding 6.5 g / L furfural (based on the volume of the reaction solution) every 24 hours, and adding calcium carbonate to control the pH of the reaction system from 4.0 to 7.0. Stop feeding after the 6th day, and add 39g / L furfural in total. Continue to react until the 10th day, stop the reaction, and the reaction process diagram is as follows: figure 1 Shown; in the figure, the abscissa represents the reaction time (d), the main ordin...

Embodiment 2

[0024] In a 3 L mechanically ventilated reaction tank, add 1.5 L of furfural solution to an initial furfural concentration of 7.0 g / L, add 20 g / L of calcium carbonate to adjust the pH of the reaction system to 4.0~7.0, and maintain the temperature of the reaction system at 30°C ± 5. Stirring speed 350~500r / min and ventilation rate 3~5vvm, keep the tank pressure at 0.01~0.02MPa, insert activated Gluconobacter oxydans to a cell concentration of 1.0g / L for cell catalysis.

[0025] The concentration of substrate furfural and product furoic acid in the reaction system is detected in real time. When the concentration of furfural is lower than 2g / L, furfural (purity higher than 97%) is automatically added to the concentration not higher than 10g / L. When adding total consumption to furfural and reaching 40g / L, stop feeding furfural to continue reaction. After reacting to 92 hours, furfural is completely consumed, and product furoic acid concentration reaches 41.5g / L, and termination r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com