High-visible-light-activity sulfur-modified carbon nitride photocatalyst as well as synthetic method and application of photocatalyst

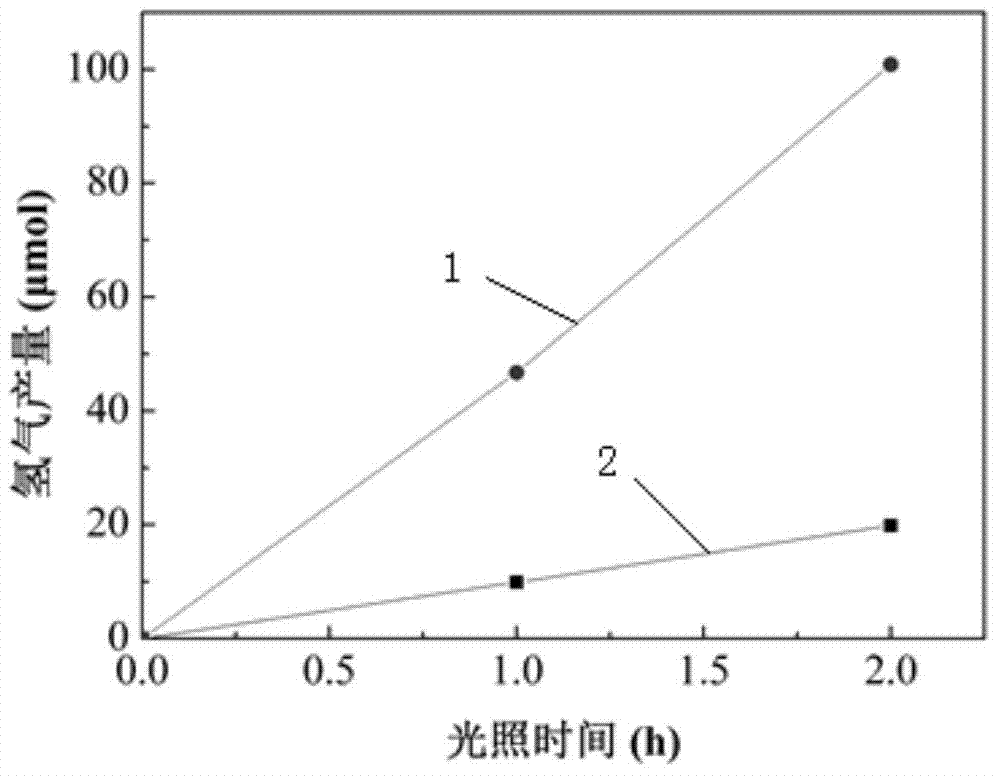

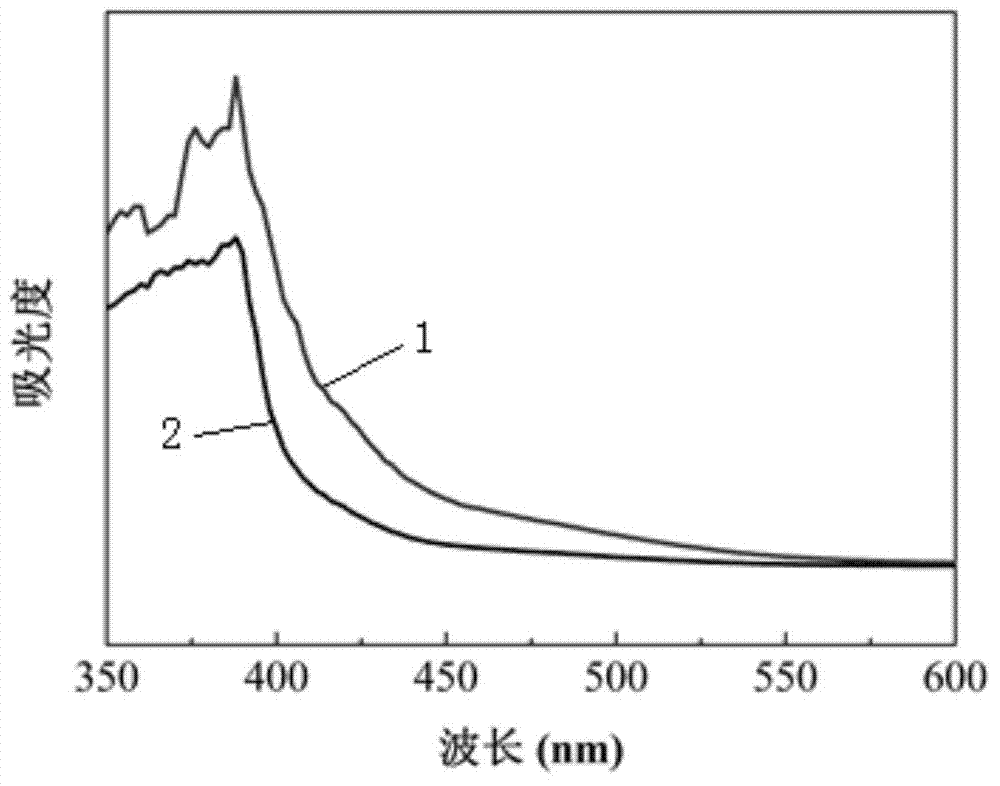

A synthesis method and visible light technology, applied in physical/chemical process catalysts, chemical instruments and methods, hydrogen production, etc., can solve the problems of low activity, high electron-hole recombination rate, small visible light absorption coefficient, etc., and achieve improved separation. Efficiency, reduced fluorescence intensity, increased visible light absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

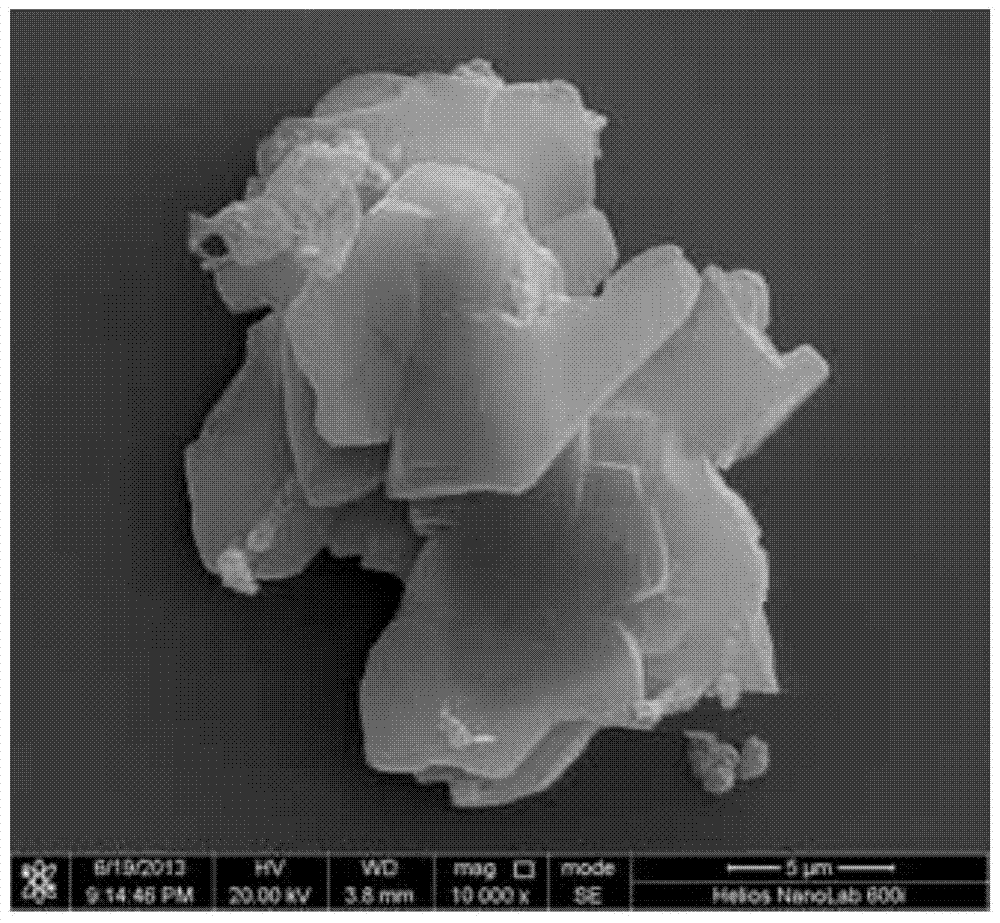

[0016] Specific embodiment one: the synthetic method of a kind of sulfur-modified carbon nitride photocatalyst with high visible light activity of this embodiment is carried out according to the following steps:

[0017] 1. Put melamine and sublimated sulfur in an agate mortar and grind until they are evenly mixed to obtain a mixed powder; the mass ratio of melamine to sublimated sulfur is 1: (0.5-2);

[0018] 2. Put the mixed powder obtained in step 1 into a porcelain boat, put it into a tube furnace, and set the temperature of the tube furnace at a rate of 5°C / min to 15°C / min under an argon atmosphere. After the room temperature is raised to 550-650° C., the temperature is maintained at 550-650° C. for 1 h to 4 h, and then cooled to room temperature under an argon atmosphere to obtain a sulfur-modified carbon nitride photocatalyst.

[0019] The raw materials used in this embodiment are commercially available analytically pure raw materials.

[0020] Sulfur is a common pale ...

specific Embodiment approach 2

[0021] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the mass ratio of melamine to sublimated sulfur in step 1 is 1:1. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0022] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, melamine and sublimed sulfur are ground in an agate mortar for 25 minutes to 35 minutes. Other steps and parameters are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com