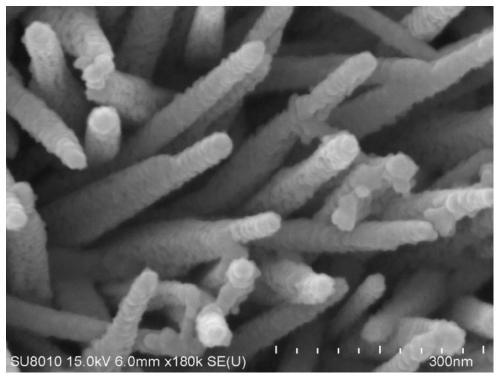

CNX/TiO2 core-shell nanowire array and manufacture method thereof

A nanowire array, core-shell technology, applied in the field of photocatalysis, can solve the problems of ineffective use of visible light, high electron-hole recombination rate, short electron migration distance, etc. performance, the effect of promoting separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a CN x / TiO 2 Core-shell nanowire array photocatalyst, its preparation method specifically comprises the following steps:

[0050] Step 1: Select a carbon cloth with a size of about 2cm×3cm as the growth substrate of titanium dioxide nanowires. The carbon cloth was ultrasonically cleaned in acetone, distilled water, and absolute ethanol in sequence. Add about 20mL n-hexane, 2 drops of TiCl to the beaker 4 , formulated into a uniform TiCl 4 hexane solution, and then add two pieces of carbon cloth to each beaker, take it out after soaking for 12 hours. After the carbon cloth was taken out, it was placed in a tube furnace. Under the air atmosphere, the heating rate was 3°C / min, from room temperature to 500°C. After a constant temperature of 30 minutes, the temperature was naturally lowered. It can be observed that the surface of the nanowire is covered with a thin layer of TiO 2 Seed layer;

[0051] Step 2: In a 200mL polytetrafluoroethylene...

Embodiment 2

[0055] Prepare a solution with methylene blue as the target pollutant to carry out an evaluation experiment on the photocatalytic degradation activity of the catalyst. The evaluation experiment is carried out in the following manner:

[0056] Will have CN x / TiO 2 The carbon cloth of the core-shell nanowire array was used as a photoanode, and the initial concentration of immersion was 1.5×10 - 5 In a mol / L methylene blue solution, a three-electrode system (PEC) is used to apply a bias voltage of 1.0V to the photoanode by connecting to an electrochemical workstation;

[0057] Before the start of the reaction, the adsorption was carried out under dark conditions, and the reaction was started after the adsorption equilibrium was reached.

[0058] A 300W Xe lamp is used as the light source, and a 420nm cut-off filter is installed on it, and the distance between the light source and the reaction liquid surface is 10cm; during the reaction time of 4 hours, sampling is performed e...

Embodiment 3

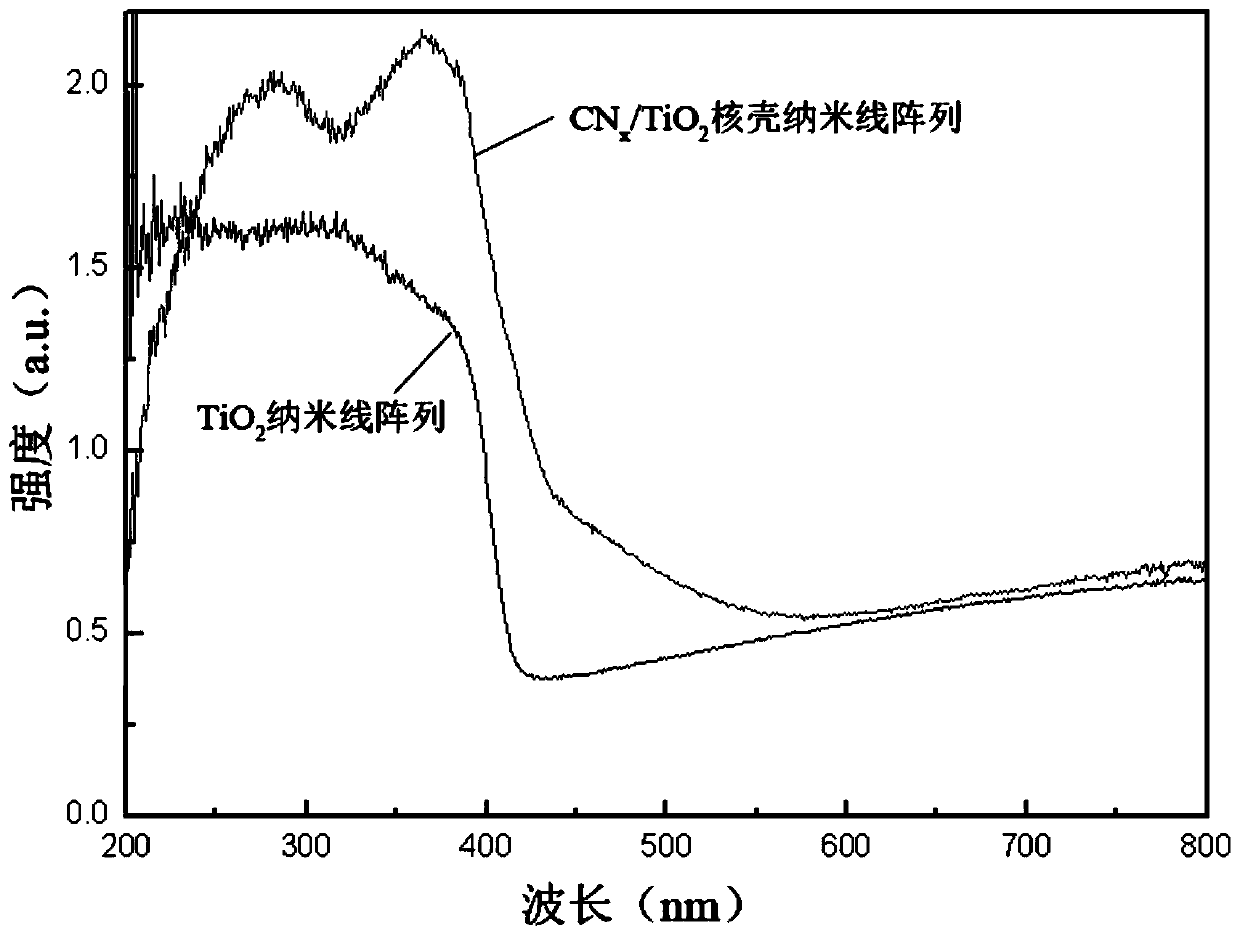

[0061] For the CN prepared in Example 1 x / TiO 2 The core-shell nanowire array is used as a photocatalyst for activity evaluation. The specific steps are similar to those in Example 2. The applied bias voltage is 2.0V, and the curve of photocatalytic degradation of methylene blue is obtained, as shown in Figure 5 shown. Depend on Figure 5 The results show that when the applied bias voltage is 2.0V, CN x / TiO 2 The photodegradation rate constant of the core-shell nanowire array is 0.01268min -1 , which is TiO in Comparative Example 1 below 2 1.4 times that of nanowire arrays. It can be seen that the CN provided by this embodiment x / TiO 2 The core-shell nanowire array photocatalyst has high photocatalytic activity, compared with pure TiO 2 Compared with nanowires, the degradation rate is significantly improved.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com