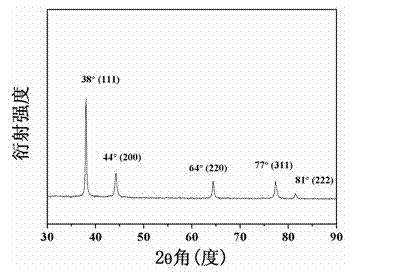

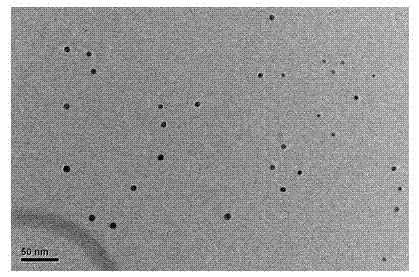

Sliver nanoparticles and production method thereof

A technology of nano-silver particles and silver salts, applied in the field of nanometers, to achieve the effect of reducing waste water and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1: First, add 20 grams of CL into a 100 ml round-bottomed flask, heat to 60°C to make it melt completely; take 0.1 gram of AgNO 3 It was added to the above mixture, and the reaction was continued for 1 hour under stirring. After the reaction, 20 g of water was added to dissolve, and Ag NPs could be obtained after centrifugation.

Embodiment 2

[0031] Example 2: First, add 40 grams of CL into a 100 ml round-bottomed flask, heat it to 80°C to melt it completely; add 0.1 grams of PVP into the CL melt, and after the PVP is completely dissolved, take 0.3 grams of AgNO 3 Add to the mixture of CL melt and PVP, and continue to react for 3 hours under stirring. At the end of the reaction, 40 g of water was added to dissolve the caprolactam, and Ag NPs could be obtained after centrifugation.

Embodiment 3

[0032] Example 3: First, add 60 grams of CL into a 100 ml round-bottomed flask, heat it to 100°C to melt it completely; add 0.5 grams of PVP into the CL melt; after the PVP is completely dissolved, take 0.5 grams of AgNO 3 Add to the mixture of CL melt and PVP, and continue to react for 6 hours under stirring. At the end of the reaction, 60 g of water was added to dissolve the caprolactam, and Ag NPs could be obtained after centrifugation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com