Preparation method of dithiocarbamic acid sulfurized cross-linking agent

A technology of dithiocarbamate and dibenzyldithiocarbamate, applied in the field of preparation of 1,6 bis-hexane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Put 39g of hexamethylene-1,6-bisthiosulfate disodium salt dihydrate, 31.3g of sodium dibenzyldithiocarbamate and 390g of dioxane into a 1000mL three-necked flask, and stir at 20°C for 10 hours. Filtrate to obtain 16 g of white sodium sulfate solids, 400 g of reaction solution of dioxane, after the reaction solution was concentrated to dryness, 70 g of product with a content of 98% was obtained, and the yield was 95%.

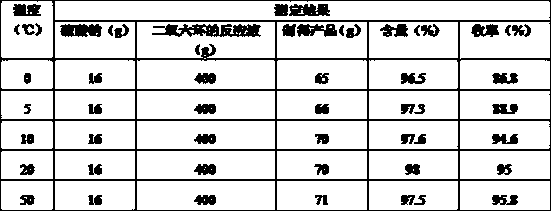

[0022] Embodiment 2, 3, 4, 5, the reaction temperature is respectively 0 ℃, 5 ℃, 10 ℃, 50 ℃, all the other implementations are as embodiment 1. The analysis results are shown in Table 1.

[0023] Table 1 Determination results using dioxane as reaction system

[0024]

[0025] It can be seen from Table 1 that as the temperature increases, the purity of the product does not change much, but the yield increases, and the product yield and purity are better at a temperature of 20°C.

Embodiment 6

[0027] 39g of hexamethylene-1,6-bisthiosulfate disodium salt dihydrate, 31.3g of sodium dibenzyldithiocarbamate and 390g of tetrahydrofuran were successively put into a 1000mL three-necked flask, and stirred at 20°C for 10 hours. After filtration, 18 g of white sodium sulfate solid and 410 g of the reaction solution of tetrahydrofuran were obtained. After the reaction solution was concentrated to dryness, 68 g of the product with a content of 98% was obtained, and the yield was 90.4%.

Embodiment 7

[0029] 39g of hexamethylene-1,6-bisthiosulfate disodium salt dihydrate, 31.3g of sodium dibenzyldithiocarbamate and 390g of toluene were successively put into a 1000mL three-necked flask, and stirred at 20°C for 20 hours. Filtrate to obtain 16 g of white sodium sulfate solid and 400 g of the reaction solution of toluene. After the reaction solution was concentrated to dryness, 60 g of the product with a content of 96.7% was obtained, and the yield was 80.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com