Environment-friendly polylactic resin prepared in presence of improved catalyst and application of polylactic resin

A technology of polylactic acid resin and catalyst, which is applied in plant protection covers, sustainable manufacturing/processing, flexible coverings, etc., can solve the problems of large environmental impact, poor safety performance, low catalytic efficiency, etc., to reduce side reactions, Effects of improving efficiency and regulating reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Add 30mL of raw material lactic acid into a 50mL single-necked flask, set the temperature to 70°C, vacuumize, distill for 7h to remove impurity water, and put it in a dry box for use. Add 10g of purified lactic acid, 0.05g of an appropriate amount of catalyst (neodecanoic acid and bismuth neodecanoate) and a certain amount of solvent 1,4-butanediol into the three-necked flask, and vacuumize with a water pump while raising the temperature. The initial temperature is set to 100°C, and gradually increase the reaction temperature by 10°C every 30min to prevent the reaction liquid from bumping. Control the highest reaction temperature and vacuum degree. After a certain period of time, stop heating, cool to room temperature, and terminate the reaction. Chloroform was added to dissolve, after dissolution, polylactic acid was precipitated by adding absolute ethanol, and dried in a vacuum oven at 50° C. for 24 hours to obtain 9.3 g of white polylactic acid resin.

Embodiment 2

[0024] In a pre-dried three-neck flask filled with argon, add 5 g of dry DL-lactide, vacuumize, blow argon, and add 0.2 mL of catalyst (neodecanoic acid and bismuth neodecanoate) in toluene solution (concentration 3.5 mM ). The toluene was vacuum-dried, sealed under reduced pressure, and reacted in an oil bath at 140°C for 12 hours. The solidified polymer was dissolved in 30 mL of dichloromethane, the precipitated polylactic acid was filtered in methanol, and dried in a vacuum oven at 50° C. for 24 hours to obtain 4.7 g of white polylactic acid resin.

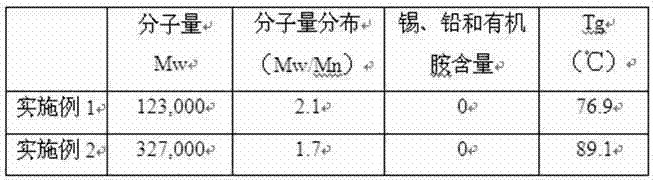

[0025] The acidity of the polylactic acid resins obtained in Examples 1 and 2 was measured. Acidity measurements were performed with a Metrohm 809Titando equipment using 0.1N KOH ethanol solution as the titrant. The results are shown in Table 1.

[0026] Referring to Table 1, the polylactic acid resins of the examples were found to have an acidity of less than 5 meq / kg. These results confirm that the preparation method of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com