Solvent-free two-component polyurethane putty for rotor wing

A two-component polyurethane, solvent-free technology, applied in the direction of filling slurry, etc., can solve the problems of unfriendly environment, insufficient cohesion, low reactivity, etc., achieve convenient construction, improve adhesion and flexibility, and good filling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 prepares long-chain vegetable oleic acid modified polyester resin

[0017] Weigh 90 parts of adipic acid, 10 parts of phthalic anhydride, 84 parts of diethylene glycol, and 11 parts of trimethylolpropane into a four-necked flask equipped with a thermometer, an oil-water separator and a stirrer, and fill it with nitrogen for about 15 minutes. Slowly heat to about 60°C after the material melts, start the agitator and continue to heat to 150°C to start reflux dehydration, control the water outlet rate and the column top temperature of the oil-water separator within the range of 100±2°C, and control the heating rate to 10°C / h, React at 160°C-220°C for 8-12 hours until the measured acid value is less than 5mgKOH / g, add 31 parts of ricinoleic acid and react for 3 hours, then add 0.2 parts of stannous octoate as a catalyst to promote the further progress of the reaction, when the oil-water separator When the column top temperature drops below 70°C, take a sample t...

Embodiment 2

[0018] Embodiment 2 prepares self-made reactive diluent

[0019] Weigh 254 parts of caprolactone monomer, 58 parts of 1,4-butanediol, 42 parts of trimethylolpropane and 0.4 parts of catalyst tetrabutyl titanate and put them into a four-necked flask equipped with a thermometer, condenser and stirrer In the process, fill with nitrogen to protect for about 15 minutes, heat slowly until the material melts, start the stirrer, continue heating for about 1 hour to 175 ° C ~ 180 ° C, keep warm for 3 hours, cool down and discharge the material, and then the self-made reactive diluent is obtained. The viscosity at 25 ° C is 280mPa·s, save for subsequent use; Wherein, caprolactone monomer: polyol: the weight ratio of catalyst is 254: 100: 0.4,

Embodiment 3

[0020] Embodiment 3 prepares solvent-free two-component polyurethane putty 1#

[0021] The long-chain vegetable oleic acid-modified polyester resin prepared in Example 1 and the self-made reactive diluent prepared in Example 2 were evenly mixed in a weight ratio of 1:4 to obtain a hydroxyl resin. Weigh 25 parts of hydroxyl resin, 3.75 parts of domestic anatase titanium dioxide, 3 parts of Shanghai # Add 0.75 parts of carbon black, 22.5 parts of precipitated barium sulfate, 45 parts of talc, 3.75 parts of dolomite, 10.1 parts of dispersant BYK-1610.1 part of defoamer AFCONA-27220.1 part and 0.1 part of leveling agent EFKA-37770. After ~15 minutes, use a three-roller to grind to a fineness of 60 μm, and the output is component A;

[0022] Commercially available crude polymethylene polyphenyl polyisocyanate and modified diphenylmethane diisocyanate are uniformly mixed in a weight ratio of 4:1 to form component B;

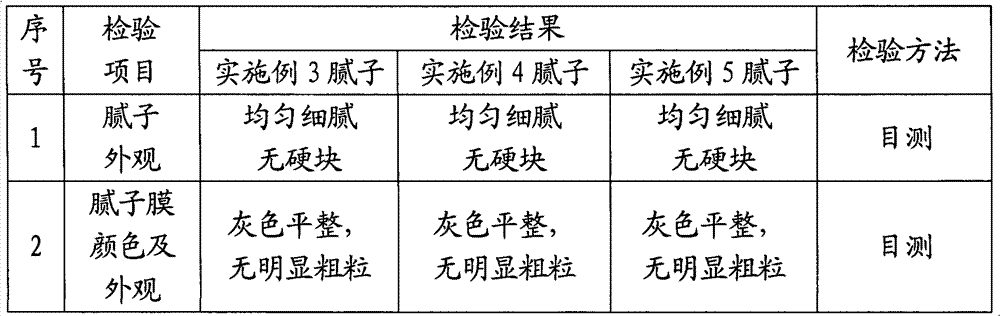

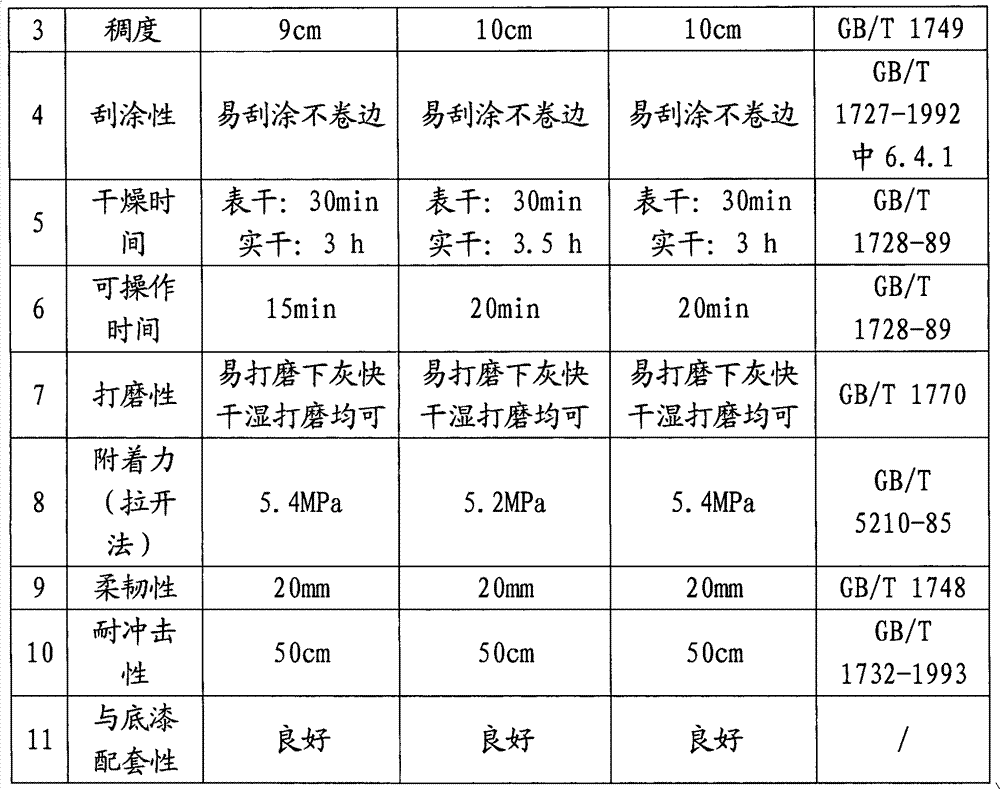

[0023] Take component A and component B and mix them evenly at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com