A kind of release agent for masking tape and preparation method thereof

A masking tape and release agent technology, applied in adhesives, defoamers, film/sheet adhesives, etc., can solve the problems of high temperature curing, release agent dependence on imports, low mobility, etc., to achieve good durability Temperature and weather resistance, less foaming, and low mobility effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

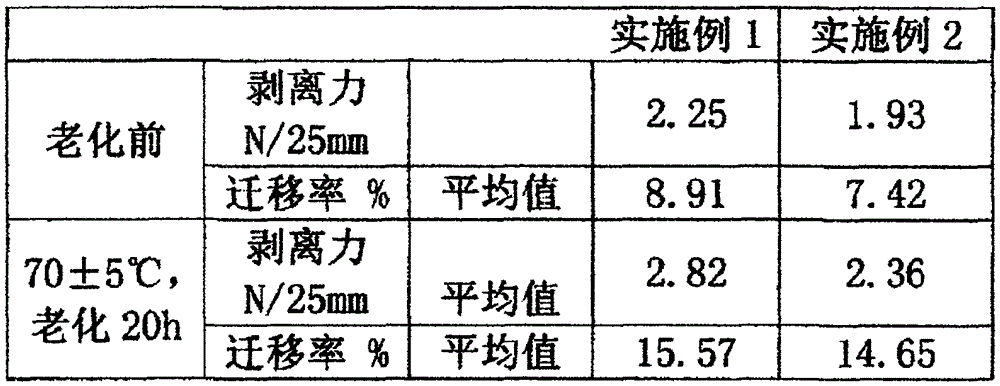

Examples

preparation example Construction

[0020] The preparation method of release agent for masking tape of the present invention comprises the following steps:

[0021] S011. Add sodium lauryl sulfate with a mass percentage of 80-90% in the above formula and deionized water with a mass percentage of 20-35% in the pre-emulsification kettle, mix and stir evenly, and then add all the ethyl acrylate in the formula ester, butyl acrylate, methyl methacrylate, styrene, succinic acid, and cross-linking monomers, and stir evenly to make a monomer pre-emulsion;

[0022] S012, adding 50-70% deionized water and the remaining sodium lauryl sulfate and all sodium bicarbonate into the reaction kettle, stirring evenly;

[0023] S013, the temperature of the reaction kettle is raised to 78-85° C., and the ammonium persulfate with a mass percentage of 60-75% and the monomer pre-emulsion with a mass percentage of 2-8% in the formula are added;

[0024] S014. After 5-15 minutes, start to add the remaining monomer pre-emulsion and ammon...

Embodiment 1

[0031] The release agent for masking tape of the embodiment of the present invention 1, it is made up of following raw material by weight:

[0032] Ethyl Acrylate 190, Butyl Acrylate 35, Methyl Methacrylate 110, Succinic Acid 8, 1,4-Butanediol Diacrylate 1.75, Deionized Water 580, Sodium Bicarbonate 0.2, Sodium Lauryl Sulfate 3.24, ammonium persulfate 2.35, defoamer 1.3, zinc glycinate 18, ammonia water 10, sodium behenyl succinate 30 and modified polysiloxane 5.

[0033] The preparation method of the release agent for masking tape of the embodiment of the present invention 1 comprises the following steps:

[0034] S111. Preparation of monomer pre-emulsion: In the pre-emulsification kettle, add sodium lauryl sulfate with a mass percentage of 80% in the formula and deionized water with a mass percentage of 25% to mix and stir evenly, then add to the formula Stir all ethyl acrylate, butyl acrylate, methyl methacrylate, and succinic acid evenly to make a monomer pre-emulsion;

...

Embodiment 2

[0043]The release agent for masking tape of the embodiment of the present invention 2, it is made up of following raw material by weight:

[0044] Ethyl Acrylate 144.5, Butyl Acrylate 62, Styrene 125, Succinic Acid 10, Deionized Water 570, Sodium Bicarbonate 0.2, Sodium Lauryl Sulfate 3.34, Sodium Persulfate 2.35, Defoamer 1.5, Zinc Glycinate 21 , ammonia water 12, long-chain alkyl surfactant 60 and modified polysiloxane 2.

[0045] The preparation method of the release agent for masking tape of the embodiment of the present invention 2 comprises the following steps:

[0046] S211. In the pre-emulsification kettle, add sodium lauryl sulfate with a mass percentage of 80% in the formula and deionized water with a mass percentage of 25% to mix and stir evenly, then add all the ethyl acrylate and butyl acrylate in the formula Ester, styrene, succinic acid, stir evenly to make monomer pre-emulsion;

[0047] S212. Add 60% deionized water, the remaining sodium lauryl sulfate and al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com