A kind of antibacterial agent for controlling the emission of polluted gas in the process of collecting and transporting domestic garbage and its preparation and application

A technology for polluting gas and domestic waste, applied in the direction of chemicals, applications, and biocides for biological control, it can solve the problems of poor broad-spectrum antibacterial properties, odor pollution, secondary pollution, etc., and achieve stable physical properties and inhibit Bacteria, human environment friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: be used for rubbish transportation process

[0057] Preparation of antibacterial mother solution:

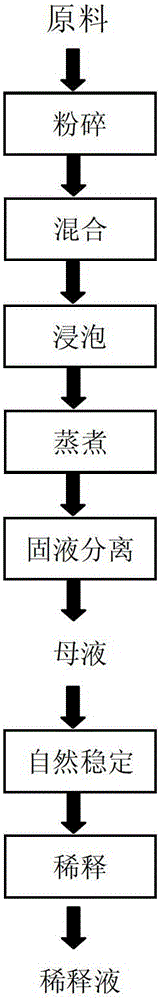

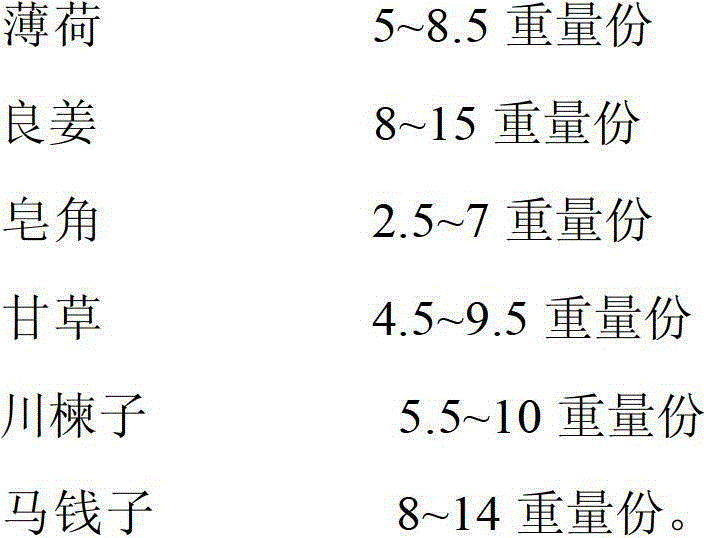

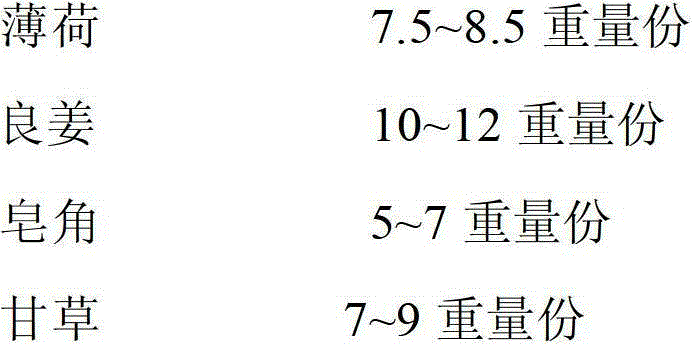

[0058] 1. The above-mentioned raw materials are pulverized into fine particles by a pulverizer according to Table 1, and the pulverization fineness reaches between 20-50 mesh.

[0059] 2. Transfer the pulverized raw materials in step 1 to the reaction kettle according to the required weight ratio, add 750kg of water, stir and mix, and soak for 25 hours.

[0060] 3. Cook for 7 hours, the cooking temperature is 80~90°C, the distillate during the cooking process is condensed and refluxed to the reactor.

[0061] 4. Cool to room temperature, transfer the cooked material in step 3 to a plate and frame filter press for solid-liquid separation, and collect the filtrate into a closed container.

[0062] 5. The filtrate obtained in step 4 is sealed and naturally stable for 2 days to obtain the antibacterial mother solution.

[0063] Take the antibacterial mother s...

Embodiment 2

[0066] Embodiment 2: for garbage loading and unloading process

[0067] Preparation of antibacterial mother solution:

[0068] 1. The above-mentioned raw materials are pulverized into fine particles by a pulverizer according to Table 1, and the pulverization fineness reaches between 25-60 mesh.

[0069] 2. Transfer the pulverized raw materials in step 1 to the reaction kettle according to the required weight ratio, add 810kg of water, stir and mix, and soak for 28 hours.

[0070] 3. Cook for 8 hours, the cooking temperature is 80~90°C, the distillate during the cooking process is condensed and refluxed to the reactor.

[0071] 4. Cool to room temperature, transfer the cooked material in step 3 to a plate and frame filter press for solid-liquid separation, and collect the filtrate into a closed container.

[0072] 5. The filtrate obtained in step 4 is sealed and naturally stable for 2 days to obtain the antibacterial mother solution.

[0073] Take the bacteriostatic mother s...

Embodiment 3

[0076] Embodiment 3: be used for rubbish stacking process

[0077] Preparation of antibacterial mother solution:

[0078] 1. The above-mentioned raw materials are pulverized into fine particles by a pulverizer according to Table 1, and the pulverization fineness reaches between 30-80 mesh.

[0079] 2. Transfer the pulverized raw materials in step 1 to the reaction kettle according to the required weight ratio, add 900kg of water, stir and mix, and soak for 30 hours.

[0080] 3. Cook for 8 hours, the cooking temperature is 80~90°C, the distillate during the cooking process is condensed and refluxed to the reactor.

[0081] 4. Cool to room temperature, transfer the cooked material in step 3 to a plate and frame filter press for solid-liquid separation, and collect the filtrate into a closed container.

[0082] 5. The filtrate obtained in step 4 is airtight and naturally stable for 3 days to obtain the antibacterial mother solution.

[0083] Take the bacteriostatic mother solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| control rate | aaaaa | aaaaa |

| control rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com