Preparation method of expanded compound feed for micropterus salmoides and snakehead fishes

A technology of extruded compound feed and snakehead, applied in animal feed, animal feed, application, etc., can solve problems such as liver enlargement, anorexia, slow growth, etc., achieve high water stability, reduce feed cost, and high feed conversion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

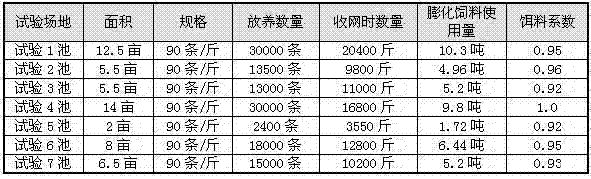

Image

Examples

Embodiment 1

[0054] A preparation method for extruded compound feed for California perch and snakehead, comprising the following steps:

[0055] ⑴ Weigh raw materials and conventional auxiliary materials according to the formula, mix, pulverize, and pass through 8-10 mesh sieves to obtain coarse materials;

[0056] ⑵ The coarse material is crushed for the second time and passed through a 60-80 mesh sieve, and mixed with other auxiliary materials in the formula to obtain a mixed material;

[0057] ⑶ Pass the mixed material through a 80-100 mesh sieve after superfine pulverization to obtain superfine powder;

[0058] ⑷ Move the ultrafine powder into the modulator, pass 14-15% of the mass of the ultrafine powder into the water vapor at 90-100°C for modulation, and then enter the extrusion extruder granulator to make feed pellets;

[0059] ⑸ Dry the feed pellets at a temperature of 95-103°C to obtain the product;

[0060] Described formula comprises raw material, conventional auxiliary mater...

Embodiment 2

[0081] A preparation method for extruded compound feed for California perch and snakehead, comprising the following steps:

[0082] ⑴ Weigh raw materials and conventional auxiliary materials according to the formula, mix, pulverize, and pass through 8-10 mesh sieves to obtain coarse materials;

[0083] ⑵ The coarse material is crushed for the second time and passed through a 60-80 mesh sieve, and mixed with other auxiliary materials in the formula to obtain a mixed material;

[0084] ⑶ Pass the mixed material through a 80-100 mesh sieve after superfine pulverization to obtain superfine powder;

[0085] ⑷ Move the ultrafine powder into the modulator, pass 14-15% of the mass of the ultrafine powder into the water vapor at 90-100°C for modulation, and then enter the extrusion extruder granulator to make feed pellets;

[0086] ⑸ Dry the feed pellets at a temperature of 95-103°C to obtain the product;

[0087] Described formula comprises raw material, conventional auxiliary mater...

Embodiment 3

[0108] A preparation method for extruded compound feed for California perch and snakehead, comprising the following steps:

[0109] ⑴ Weigh raw materials and conventional auxiliary materials according to the formula, mix, pulverize, and pass through 8-10 mesh sieves to obtain coarse materials;

[0110] ⑵ The coarse material is crushed for the second time and passed through a 60-80 mesh sieve, and mixed with other auxiliary materials in the formula to obtain a mixed material;

[0111] ⑶ Pass the mixed material through a 80-100 mesh sieve after superfine pulverization to obtain superfine powder;

[0112] ⑷ Move the ultrafine powder into the modulator, pass 14-15% of the mass of the ultrafine powder into the water vapor at 90-100°C for modulation, and then enter the extrusion extruder granulator to make feed pellets;

[0113] ⑸ Dry the feed pellets at a temperature of 95-103°C to obtain the product;

[0114] Described formula comprises raw material, conventional auxiliary mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com