Preparation method and applications of royal jelly microcapsule

A technology of royal jelly and microcapsules, which is applied in the field of preparation of royal jelly microcapsules, can solve the problems that hinder the promotion and popularization of royal jelly freeze-dried powder, achieve the effects of stabilizing active ingredients, expanding the scope of application, and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

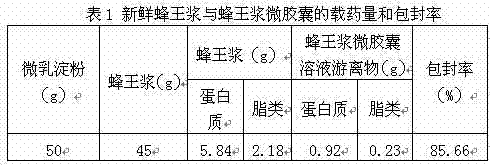

Embodiment 1

[0022] Mix 45 g of fresh royal jelly with 100 mL of water and mix well. Weigh 50 g of microporous starch into a beaker, add the prepared royal jelly extract, stir for 15 min to completely absorb the active ingredients of royal jelly, and prepare a microporous starch emulsion. Prepare 100 mL of gelatin solution with a concentration of 5% by gelatin and gum arabic at a ratio of 1:2, and add the prepared microporous starch emulsion into the prepared gelatin solution. This process is carried out on a magnetic stirrer , keep the temperature at 25°C; after the polymerization reaction, put the mixture in the refrigerator to cool overnight at 4°C to speed up the precipitation process. The cooled mixture was frozen at -18°C and freeze-dried. The freeze-drying conditions are: condensation temperature -45°C, pressure 0.5kPa, final temperature 20°C. Finally, powdered royal jelly microcapsules are obtained. The spicy and astringent taste of microencapsulated royal jelly is masked and th...

Embodiment 2

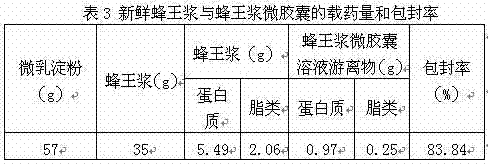

[0030] Mix 35 g of fresh royal jelly with 100 mL of water and mix well. Weigh 57 g of microporous starch into a beaker, add the prepared royal jelly extract, stir for 15 min to completely absorb the active ingredients of royal jelly, and prepare a microporous starch emulsion. Prepare 100 mL of colloidal solution with a concentration of 8% by gelatin and gum arabic at a ratio of 1:2, and add the prepared microporous starch emulsion into the prepared colloidal solution. This process is carried out on a magnetic stirrer , keep the temperature at 30°C; after the polymerization reaction, put the mixture in the refrigerator to cool overnight at 4°C to speed up the precipitation process. The cooled mixture was frozen at -18°C and freeze-dried. The freeze-drying conditions are: condensation temperature -50°C, pressure 0.7 kPa, final temperature 23°C. Finally, powdered royal jelly microcapsules are obtained.

[0031] The content of protein and lipid in fresh royal jelly and the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com