Method for preparing composite nanofiltration membrane by employing interfacial polymerization process

A technology of composite nanofiltration membrane and interfacial polymerization method, which is applied in the field of composite nanofiltration membrane prepared by interfacial polymerization method, can solve the problems of high energy consumption, high operating pressure of nanofiltration membrane, and reduce the operating pressure of nanofiltration membrane, so as to save energy consumption, good application prospects, and low operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

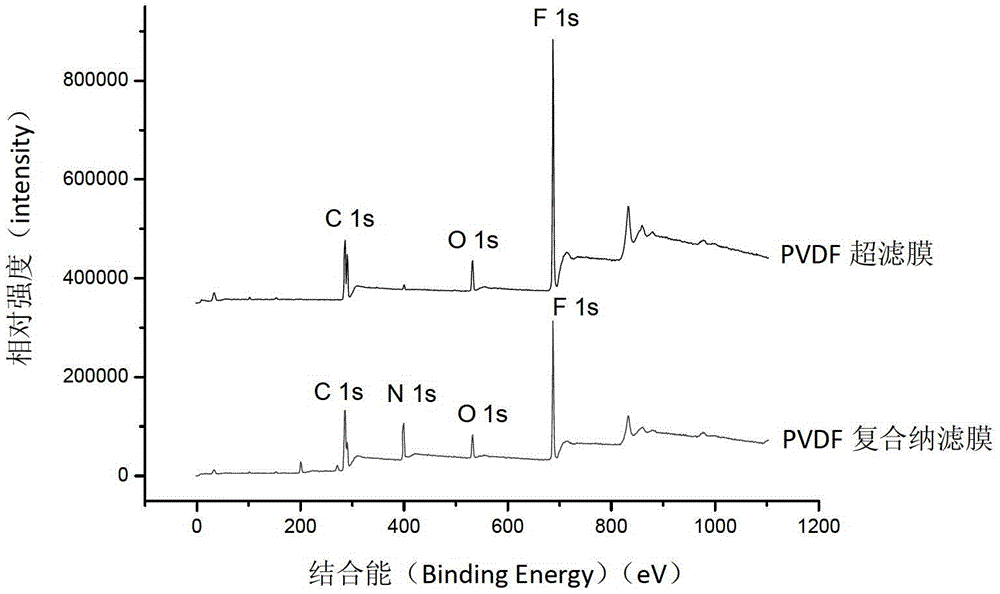

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment, the PVDF ultrafiltration membrane is used as the porous support layer, the aqueous solution of piperazine is used as the water phase solution, and the toluene solution of cyanuric chloride is used as the oil phase solution, and the composite nanofiltration membrane is prepared by interfacial polymerization. Specific steps are as follows:

[0030] Step 1: Use PVDF flat ultrafiltration membrane as the porous support layer;

[0031] Step 2: configure the aqueous phase solution, the mass percentage concentration of piperazine in the aqueous phase solution is 1.0%, and triethylamine and sodium lauryl sulfate are also included in the aqueous phase solution, wherein, the quality of sodium lauryl sulfate The percentage concentration is 0.1%;

[0032] Configure the oil phase solution, the mass percent concentration of cyanuric chloride in the oil phase solution is 1.0%;

[0033] The ratio of the amount of triethylamine in the aqueous phase solution to the a...

Embodiment 2

[0041] In this embodiment, the PVDF hollow fiber ultrafiltration membrane is used as the porous support layer, the aqueous solution of m-phenylenediamine is used as the water phase solution, and the benzene solution of cyanuric chloride is used as the oil phase solution, and the composite nanofiltration membrane is prepared by interfacial polymerization. .

[0042] Specific steps are as follows:

[0043] Step 1: Use PVDF hollow fiber ultrafiltration membrane as the porous support layer;

[0044] Step 2: configure the water phase solution, the mass percentage concentration of m-phenylenediamine in the water phase solution is 1.0%, and the water phase solution also includes potassium hydroxide and sodium dodecylsulfonate, wherein dodecylsulfonate The mass percent concentration of sodium nitrate is 0.1%;

[0045] Configure the oil phase solution, the mass percent concentration of cyanuric chloride in the oil phase solution is 0.8%;

[0046] The ratio of the amount of potassium...

Embodiment 3

[0054] In this example, the polysulfone hollow fiber ultrafiltration membrane is used as the porous support layer, the aqueous solution of triethanolamine is used as the aqueous phase solution, the ethyl acetate solution of hexachlorocyclotriphosphazene is used as the oil phase solution, and the composite Nanofiltration. Specific steps are as follows:

[0055] Step 1: using polysulfone hollow fiber ultrafiltration membrane as a porous support layer;

[0056] Step 2: configure the aqueous phase solution, the mass percentage concentration of triethanolamine in the aqueous phase solution is 0.1%, potassium hydroxide and cetyl dimethyl benzyl ammonium chloride are also included in the aqueous phase solution, wherein, cetyl Alkyl dimethyl benzyl ammonium chloride mass percent concentration is 0.05%;

[0057] An oil phase solution is configured, and the mass percent concentration of hexachlorocyclotriphosphazene in the oil phase solution is 0.3%.

[0058] The ratio of the amount ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com