Method for one-kettle preparation of fluorosilicone block polymer-modified inorganic material

An inorganic material, fluorosilicon block technology, applied in the direction of biocide-containing paints, antifouling/underwater coatings, coatings, etc., can solve the problems of increased cost and many steps, achieve high conversion rate and reduce production costs , the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

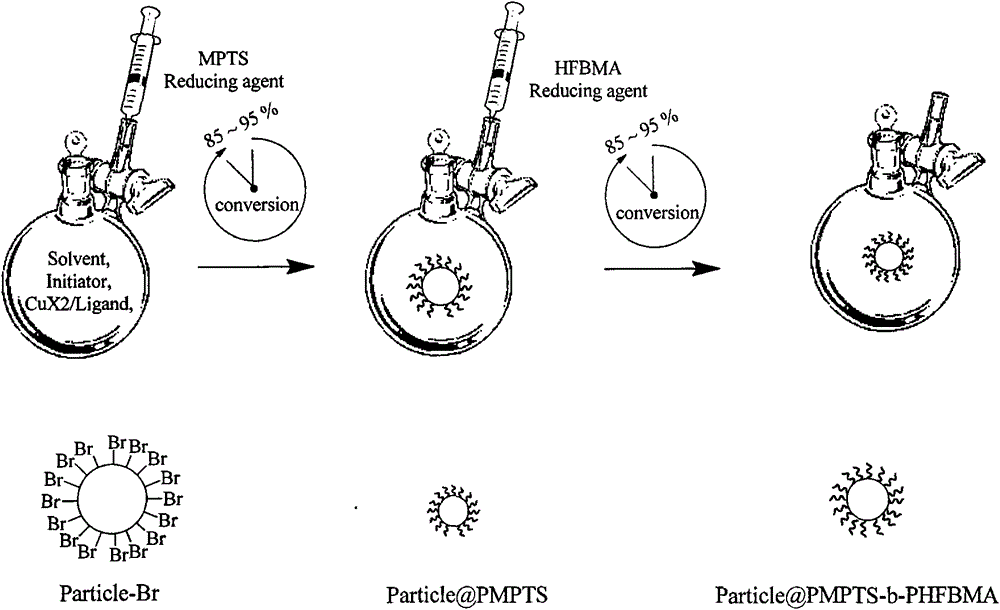

Method used

Image

Examples

Embodiment 1

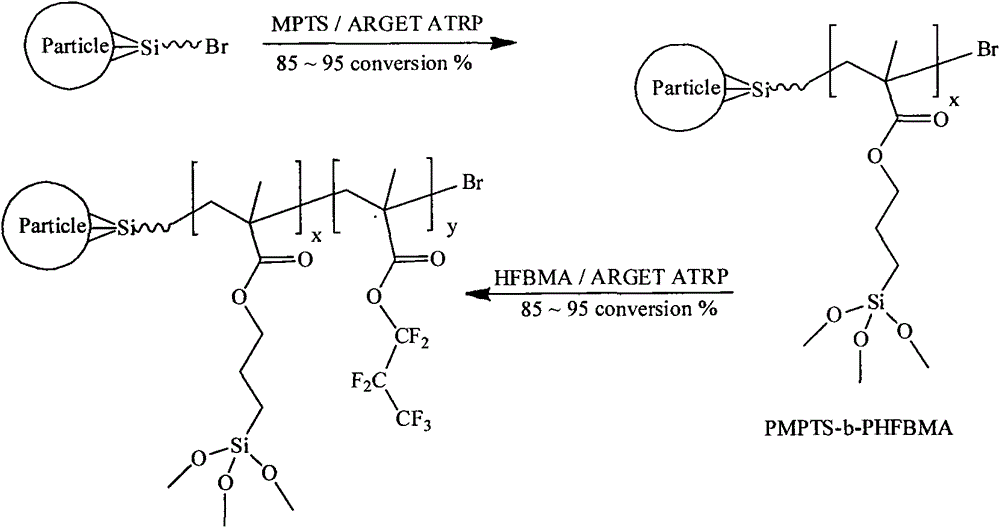

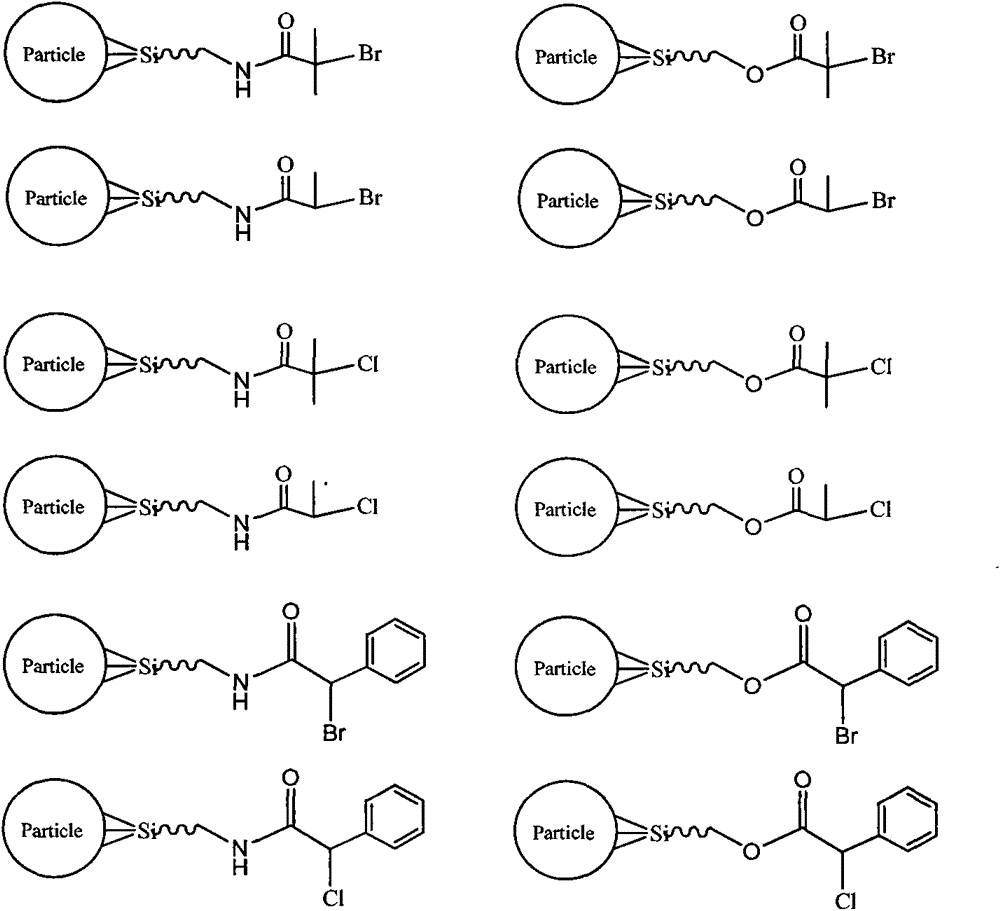

[0034] Add 1 mol of 2-bromoisobutyrate-modified silica on the surface, 0.0025 mol of copper bromide, 0.01 mol of TPMA and 50 mol of toluene into the reaction flask, blow nitrogen gas for 10 minutes, heat to 60°C, and then Add a mixture of 100mol 3-methacryloxypropyltrimethoxysilane (MPTS) and 0.025mol stannous octoate, and slowly add 100mol heptafluorobutyl methacrylate diluted with 100mol toluene when the monomer conversion rate reaches 85%. The mixture of (HFBMA) and 0.05mol stannous octoate is put into the reaction bottle, feed nitrogen for 10 minutes, heat to 60 ℃, when the closed system reacts until the monomer conversion rate reaches 85%, open and stir, the main component of the obtained product is poly 3-Methacryloxypropyltrimethoxysilane-b-polyheptafluorobutylmethacrylate modified silica.

Embodiment 2

[0036] Diatomaceous earth modified with 1mol2-bromoisobutyramide group on the surface, 0.05mol copper bromide, 0.2molMe 6 Add TREN and 250mol xylene into the reaction flask together, feed nitrogen for 30 minutes, heat to 80°C, then add 250mol 3-methacryloxypropyltrimethoxysilane (MPTS) and a mixture of 0.025-1mol ascorbic acid, When the conversion rate of the monomer reaches 90%, slowly add a mixture of 250 mol of heptafluorobutyl methacrylate (HFBMA) and 0.5 mol of ascorbic acid diluted with 250 mol of xylene into the reaction flask, feed nitrogen gas for 10 to 60 minutes, and heat to 80 ℃, react in a closed system until the conversion rate of the monomer reaches 90%, and stir in the open to obtain a product whose main component is poly-3-methacryloxypropyltrimethoxysilane-b-polyheptafluorobutyl methacrylate Modified silica.

Embodiment 3

[0038] Add montmorillonite with 1 mol of 2-bromopropionate groups on the surface, 0.1 mol of copper bromide, 0.4 mol of TPMA and 500 mol of anisole into the reaction flask, blow nitrogen gas for 60 minutes, heat to 95°C, and then Add a mixture of 500mol 3-methacryloxypropyltrimethoxysilane (MPTS) and 1mol stannous octoate, and slowly add 500mol heptafluorobutyl methacrylate diluted with 500mol anisole when the monomer conversion rate reaches 95%. Put the mixture of base ester (HFBMA) and 1mol stannous octoate into the reaction flask, feed nitrogen gas for 60 minutes, heat to 95° C., and when the closed system reacts to the monomer conversion rate reaches 95%, stir in the open to obtain the main component of the product: Poly(3-methacryloxypropyltrimethoxysilane)-b-polyheptafluorobutyl methacrylate modified silica.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com