Spraying method for preparing graphene/polymer emulsion composite thin film material

A technology of polymer emulsion and composite film, which is applied in the field of preparation of graphene/polymer emulsion nanocomposite film materials, can solve the problems of complex operation of in-situ polymerization, reduction of polymer molecular weight, and poor dispersion of graphene, etc., to achieve Large-scale industrial production, good stability, and excellent barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

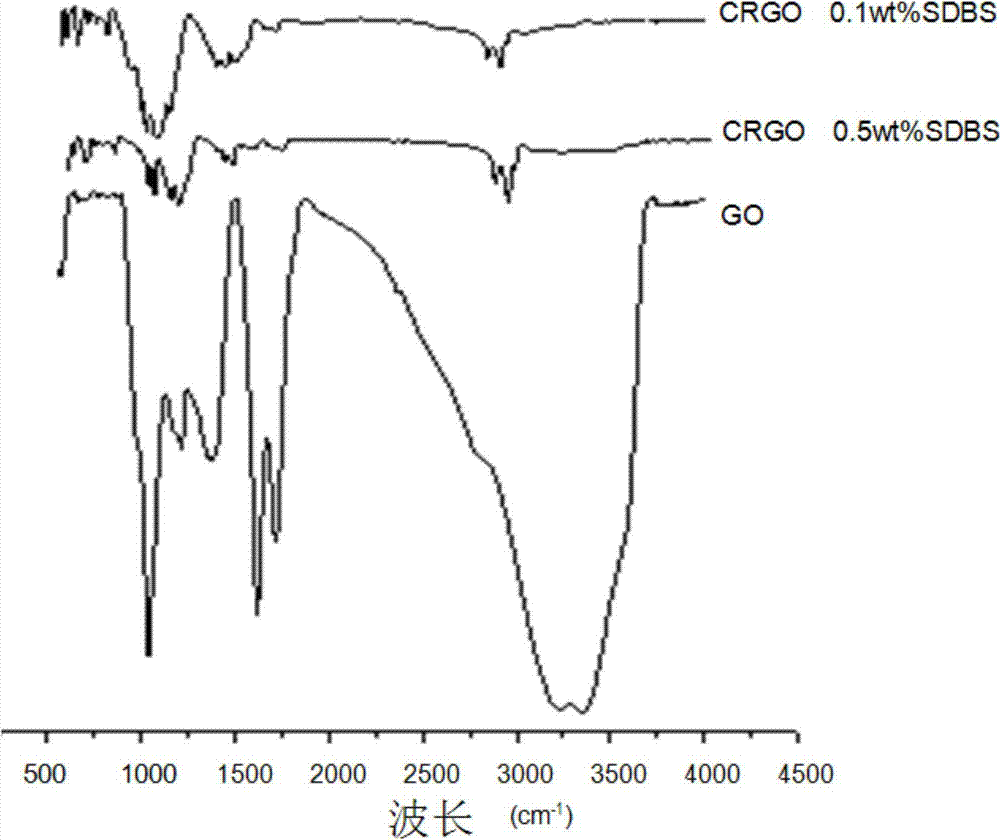

[0042] Prepare 400ml of graphite oxide aqueous solution with a concentration of 1.0mg / ml, ultrasonically peel and disperse for 3 hours; add sodium dodecylbenzenesulfonate with a mass fraction of 0.5wt%, mix and stir evenly, and ultrasonically disperse for 1 hour; add 0.4ml of mass fraction With a fraction of 85% hydrazine hydrate, continue to ultrasonically disperse for 3 hours to obtain a black graphene hydrosol. Mix the styrene-acrylic emulsion and graphene hydrosol uniformly according to the volume ratio of 1:5 to prepare the graphene / styrene-acrylic composite emulsion; heat the polytetrafluoroethylene substrate to 100C, spray the graphene / polymer nano-composite emulsion, Repeat 30 times by spraying for 1 minute with an interval of 2 minutes to obtain a graphene / styrene-acrylic nanocomposite film. Such as figure 1 As shown in the graphene infrared characterization (IR) diagram, it can be seen that the reduced graphene oxide graphene has a good degree of reduction and can r...

Embodiment 2

[0044] Prepare 400ml of graphite oxide aqueous solution with a concentration of 0.5mg / ml, ultrasonically peel and disperse for 3 hours; add sodium dodecylbenzenesulfonate with a mass fraction of 0.1wt%, mix and stir evenly, and ultrasonically disperse for 1 hour; add 0.4ml of mass fraction With a fraction of 85% hydrazine hydrate, continue ultrasonic dispersion for 2 hours to obtain a black graphene hydrosol. Mix the styrene-acrylic emulsion, graphene hydrosol and deionized water according to the volume ratio of 1:3:2 to prepare the graphene / styrene-acrylic composite emulsion; spray it on the polytetrafluoroethylene substrate at 100°C, Spray for 1 minute with an interval of 2 minutes, and repeat this 30 times to obtain a graphene / styrene-acrylic nanocomposite film.

[0045] Such as figure 1 As shown in the graphene infrared characterization (IR) figure, it can be seen that reduced graphene oxide graphene has a good degree of reduction, can remove most of the oxygen-containing...

Embodiment 3

[0047] Prepare 400ml of graphite oxide aqueous solution with a concentration of 1.0mg / ml, ultrasonically peel and disperse for 2 hours; add sodium dodecylbenzenesulfonate with a mass fraction of 0.2wt%, mix and stir evenly, and ultrasonically disperse for 1 hour; add 0.4ml of mass With a fraction of 85% hydrazine hydrate, continue to ultrasonically disperse for 3 hours to obtain a black graphene hydrosol. Mix the styrene-butadiene emulsion, graphene hydrosol and deionized water evenly according to the volume ratio of 1:1:1 to prepare the graphene / styrene-butadiene composite emulsion; configure 1.0mmg / ml dodecylbenzenesulfonic acid Sodium aqueous solution, sprayed on the 100°C PET substrate, sprayed for 1 minute, with an interval of 2 minutes, and repeated 15 times; then sprayed the graphene / butadiene nanocomposite emulsion on the substrate, sprayed for 1 minute, with an interval of 2 minutes, and repeated for 30 times. Once, the graphene / butadiene-butadiene nanocomposite film ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com