Edible peanut protein isolate antimicrobial coating and preparation method thereof

A peanut protein isolate and antibacterial film technology, applied in flexible coverings, transportation and packaging, packaging, etc., to achieve the effects of accelerating industrial production, accelerating practical commercial applications, improving film-forming properties and anti-corrosion and fresh-keeping capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

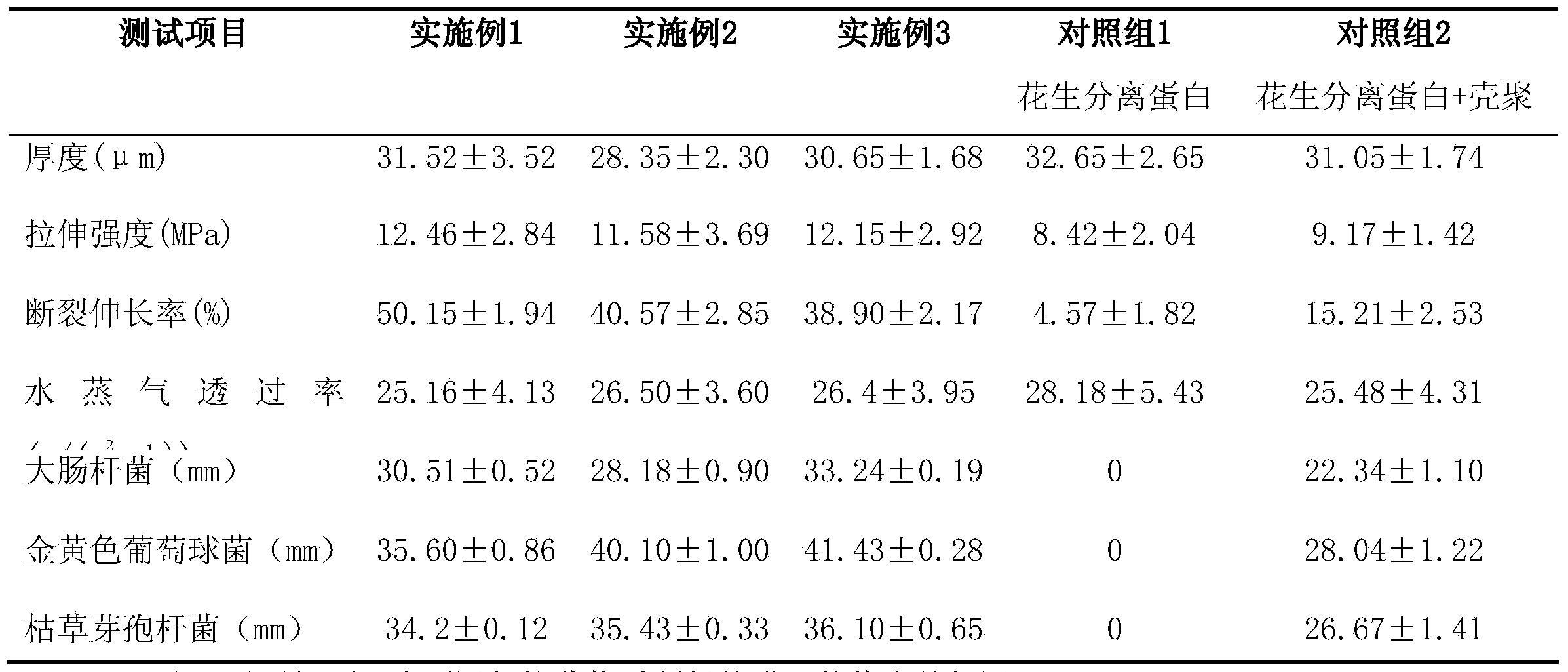

Embodiment 1

[0031] Weigh 3g of peanut protein isolate, dissolve it in 50mL of distilled water, adjust the pH to 9.0 with 0.1N NaOH, stir and dissolve to form a peanut protein isolate solution; weigh 1g of chitosan and dissolve it in 50mL of 2% (V / V) acetic acid solution, stir Dissolved into chitosan solution; mix the two solutions, add 2mL glycerin as a plasticizer, stir evenly with a glass rod, put in an ultrasonic water bath at 75°C for 30min, then cool it to 40°C, add 4mL clove essential oil, and use a homogenizer After homogenizing the above solution for 1 min, put it into a vacuum degasser for degassing 3-4 times, take 50mL of film-forming liquid and pour it on a 20cm×20cm plexiglass plate, cast it, and place it in a blast drying oven at 50°C After internal drying for 10 hours, the film was peeled off, and the peeled film was placed in a desiccator with a relative humidity of 52% (filled with saturated magnesium nitrate solution to maintain its humidity), and its film-forming performa...

Embodiment 2

[0033] Weigh 3g of peanut protein isolate, dissolve it in 50mL of distilled water, adjust the pH to 9.0 with 0.1N NaOH, stir and dissolve to form a peanut protein isolate solution; weigh 1g of chitosan and dissolve it in 50mL of 2% (V / V) acetic acid solution, stir Dissolved into chitosan solution; mix the two solutions, add 2mL glycerin as a plasticizer, stir evenly with a glass rod, put in an ultrasonic water bath at 75°C for 30min, then cool it to 40°C, add Nisin at 5000IU / mL, use Homogenizer Homogenize the above solution for 1min, put it into a vacuum degasser for degassing 3-4 times, take 50mL of film-forming liquid and pour it on a 20cm×20cm plexiglass plate, cast it, and blow it at 50°C After drying in a drying oven for 10 hours, peel off the film, put the peeled film in a desiccator with a relative humidity of 52% (filled with saturated magnesium nitrate solution to maintain its humidity), and measure its film-forming performance and antibacterial effect after equilibrat...

Embodiment 3

[0035] Weigh 3g of peanut protein isolate, dissolve it in 50mL of distilled water, adjust the pH to 9.0 with 0.1N NaOH, stir and dissolve to form a peanut protein isolate solution; weigh 1g of chitosan and dissolve it in 50mL of 2% (V / V) acetic acid solution, stir Dissolved into a chitosan solution; mix the two solutions, add 2mL glycerin as a plasticizer, stir evenly with a glass rod, put in a 75°C ultrasonic water bath for 30min, then cool it to 40°C, add 4mL clove essential oil and press 5000IU / Add Nisin to mL, homogenize the above solution for 1min with a homogenizer, put it into a vacuum degasser for degassing 3-4 times, take 50mL of film-forming liquid and pour it on a 20cm×20cm plexiglass plate, and tape-cast it. After drying in a blast drying oven at 50°C for 10 hours, peel off the film, place the peeled film in a desiccator with a relative humidity of 52% (filled with saturated magnesium nitrate solution to maintain its humidity), and measure its film formation after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com