Water-based paint capable of shielding Wi-Fi signals as well as preparation and application methods thereof

A water-based coating and signal technology, applied in conductive coatings, carboxyl rubber coatings, polyurea/polyurethane coatings, etc., can solve problems such as fire hazards and environmental pollution, and achieve increased conductivity, wide application range, and excellent Wi-Fi signals The effect of shielding ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

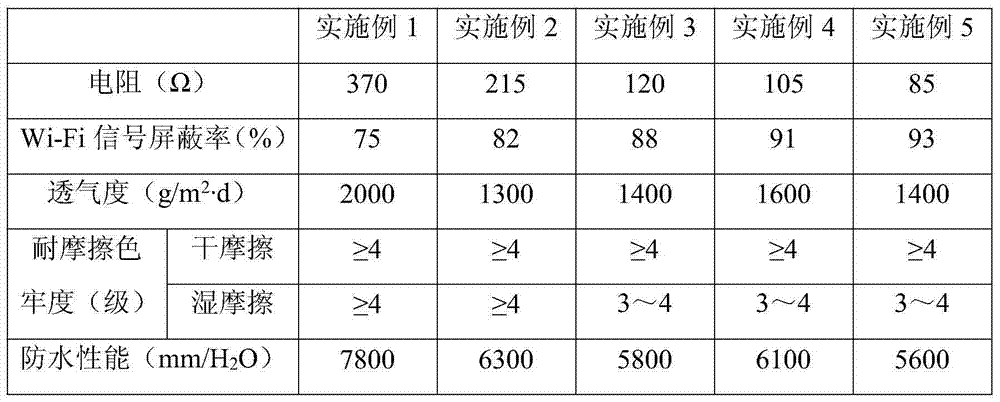

Examples

Embodiment 1

[0028] A water-based coating for shielding Wi-Fi signals and a preparation method thereof, the weight fraction components of the water-based coating and the preparation method are as follows:

[0029] In 100 parts of methacrylic latex, add 3 parts of polyacrylamide dispersant, 30 parts of 200 mesh nickel powder and 3 parts of polyacrylate leveling agent, stir and disperse at a speed of 300r / min for 10min under a high-speed stirrer;

[0030] Then add 50 parts of 200 mesh conductive carbon black, 80 parts of deionized water and 8 parts of ionic octadecadequaternary ammonium salt polymer-type water-based conductive agent in the uniformly dispersed slurry, at a speed of 600r / min under the high-speed stirrer Stir and disperse for 20 minutes to obtain a uniform water-based paint.

[0031] The resulting coating was evenly coated on the surface of the substrate described in the invention patent "A Modified Polyolefin Paper Without Plant Fiber" (authorized announcement number: CN101462...

Embodiment 2

[0033] A water-based coating for shielding Wi-Fi signals and a preparation method thereof, the weight fraction components of the water-based coating and the preparation method are as follows:

[0034] In 100 parts of methyl acrylate latex, add 5 parts of Gur gum dispersant, 50 parts of 500 mesh nickel powder and 6 parts of modified polyacrylate leveling agent, stir and disperse at a speed of 500r / min for 20min under a high-speed stirrer ;

[0035] Then add 90 parts of 500 mesh conductive carbon black, 140 parts of deionized water and 6 parts of ionic octadecadequaternary ammonium salt polymer type water-based conductive agent in the uniformly dispersed slurry, at a speed of 700r / min under the high-speed stirrer Stir and disperse for 45 minutes to obtain a uniform water-based paint.

[0036] The resulting coating was evenly coated on the surface of the substrate described in the invention patent "A Modified Polyolefin Paper Without Plant Fiber" (authorized announcement number:...

Embodiment 3

[0038] A water-based coating for shielding Wi-Fi signals and a preparation method thereof, the weight fraction components of the water-based coating and the preparation method are as follows:

[0039]In 100 parts of 2-ethyl methacrylate latex, add 5 parts of Onkel HLD-12 type dispersant, 80 parts of 1000 mesh nickel powder and 8 parts of polyether modified polydimethylsiloxane type leveling agent , stir and disperse at a rate of 600r / min for 20min under a high-speed stirrer;

[0040] Then add 80 parts of 1000 meshes of conductive carbon black, 160 parts of deionized water and 4 parts of alkanol ammonium salt type water-based conductive agent of unsaturated acid carboxylate in the uniformly dispersed slurry, under high-speed stirrer with 800r / min speed stirring dispersion 60min to obtain a uniform water-based paint.

[0041] The resulting coating was evenly coated on the surface of the substrate described in the invention patent "Inorganic Powder Highly Filled Polyolefin Deco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com