Method for preparing rhamnose by using rutin

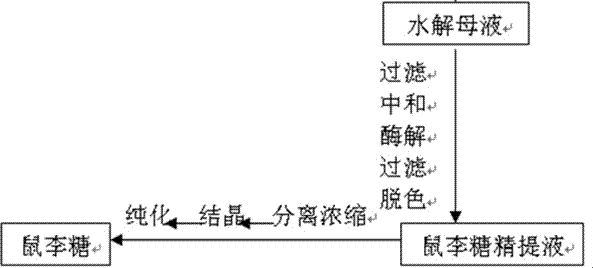

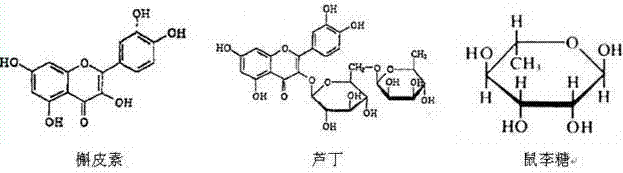

A technology of rhamnose and rutin, applied in the field of flavonoid extraction, can solve the problems of low product purity, failure to meet international standards, incomplete utilization of resources, complicated and tedious processes, etc., and achieves complete hydrolysis reaction and shortened time The effect of shortening the production cycle and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step a: Collect 10kg of Sophora japonica flower buds (wet weight), steam the collected Sophora japonica flower buds in 100°C water vapor for 12 minutes to eliminate degradative enzymes, take out the steamed flower buds, dry them in sequence, crush them, and infiltrate them. A leaching solution containing 18% sodium carbonate, 20% sodium bisulfite, and 30% calcium chloride, the ratio of the leaching solution to Sophora japonica flower buds (wet weight) is 2.5L: 1kg, and the solution obtained after percolation is filtered to remove slag to obtain a crude extract.

[0026] Step b: Add the natural traditional Chinese medicine clarifier KBT-ZTC to the crude extract obtained in step a. The ratio of the flocculation clarifier to the crude extract is 3.0g:100L. After adding the flocculation clarifier, stir gently to make the flocculation clarifier Distribute evenly in the extract, and then let it stand for 25 minutes to precipitate impurities and remove precipitates. Add antiox...

Embodiment 2

[0031] Step a: Collect 10kg of Sophora japonica flower buds (wet weight), steam the collected Sophora japonica flower buds in 120°C water vapor for 10 minutes to eliminate degradative enzymes, take out the steamed flower buds, dry them in sequence, crush them, and infiltrate them. A leaching solution containing 15% sodium carbonate, 30% sodium bisulfite, and 40% calcium chloride, the ratio of the leaching solution to Sophora japonica flower buds (wet weight) is 3.0L: 1kg, and the solution obtained after percolation is filtered to remove slag to obtain a crude extract.

[0032] Step b: Add the natural traditional Chinese medicine clarifier KBT-ZTC to the crude extract obtained in step a, the ratio of the flocculation clarifier to the crude extract is 2.5g:100L, add the flocculation clarifier and stir gently to make the flocculation clarifier in the crude Distribute evenly in the extract, and then let it stand for 30 minutes to precipitate impurities and remove precipitates. Add...

Embodiment 3

[0037] Step a: Collect 10kg of Sophora japonica flower buds (wet weight), steam the collected Sophora japonica flower buds in 115°C water vapor for 13 minutes to eliminate degradative enzymes, take out the steamed flower buds, dry them in sequence, crush them, and infiltrate them. A leaching solution containing 30% sodium carbonate, 15% sodium bisulfite, and 30% calcium chloride, the ratio of the leaching solution to Sophora japonica flower buds (wet weight) is 2.0L: 1kg, and the solution obtained after percolation is filtered to remove slag to obtain a crude extract.

[0038] Step b: Add the natural traditional Chinese medicine clarifier KBT-ZTC to the crude extract obtained in step a, the ratio of the flocculation clarifier to the crude extract is 5.0g:100L, add the flocculation clarifier and stir gently to make the flocculation clarifier in the crude Evenly distribute in the extract, and then stand still for 20 minutes to precipitate impurities and remove precipitates. Add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com