A method of preparing nb-si based super high temperature alloy by laser selective melting technology

A laser selective melting and ultra-high temperature alloy technology, applied in the direction of improving energy efficiency and process efficiency, can solve the difficulty in meeting the requirements of Nb-Si-based alloy investment casting molding, multi-machining and post-processing, and limit alloy properties and other problems, to achieve the effect of eliminating the design and manufacturing process of molds, avoiding machining and post-processing, and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

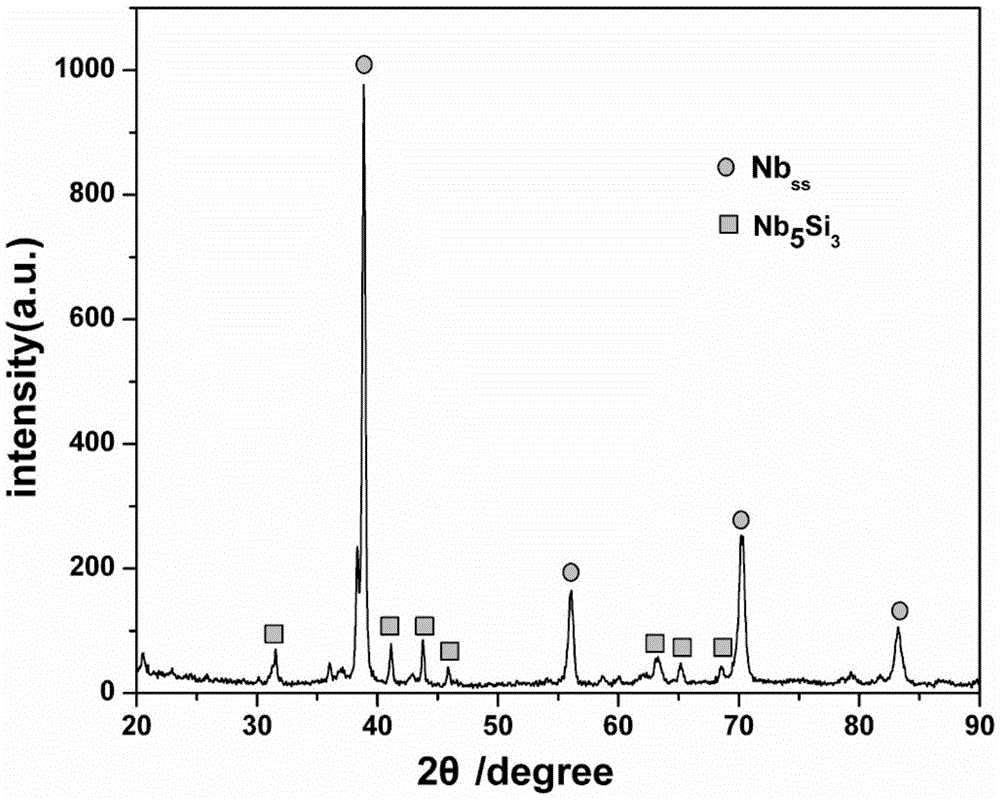

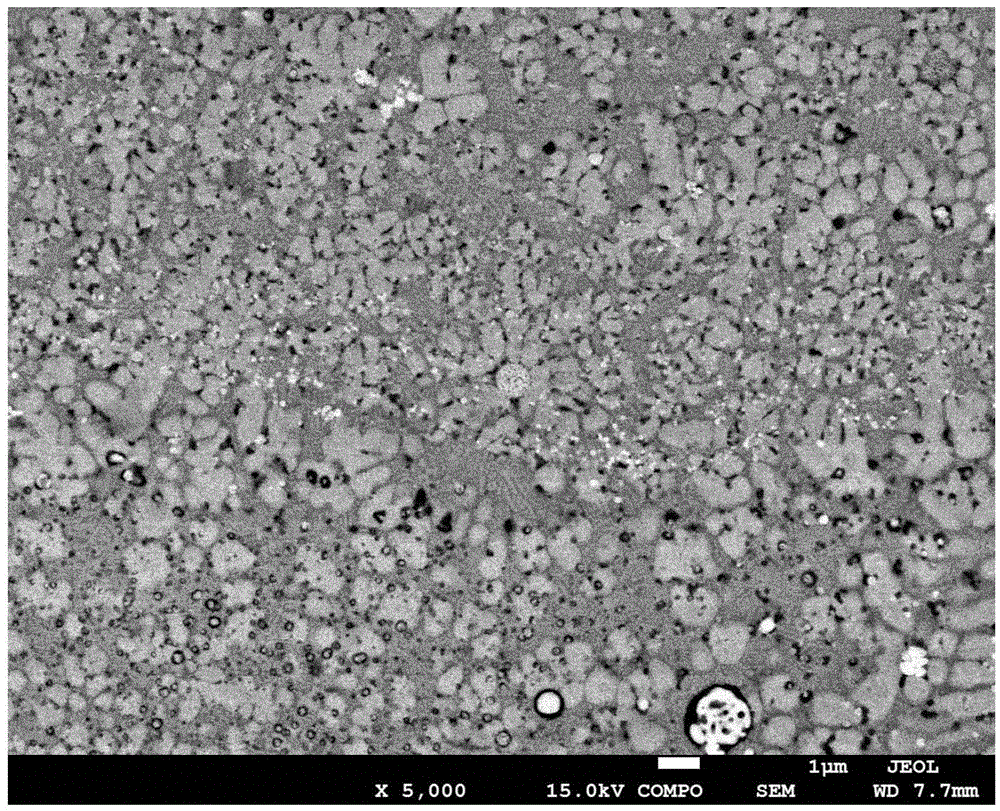

Embodiment 1

[0027]Using SLM technology to prepare Nb-18Si-24Ti-2Cr-2Al-2Hf (at.%, atomic percentage) super high temperature alloy: the SLM laser selective melting system used mainly includes: Nd-YAG laser, computer system for forming control, Powder feeding system and argon atmosphere protection device;

[0028] 1. Select Nb-18Si-24Ti-2Cr-2Al-2Hf pre-alloyed powder prepared by argon atomization method, the powder is spherical or nearly spherical, and the diameter is between 10 and 60 μm;

[0029] 2. According to the shape of the alloy parts to be processed, use the computer to establish a three-dimensional CAD model, and use the slicing software to perform layered slice discretization in the height direction of the model. Section profile information and scanning processing path, save multi-layer slice information as STL file, and transfer to SLM laser melting system;

[0030] 3. Put the powder into the forming cavity, and fix the Ti6Al4V forming substrate with a thickness of 10mm on the ...

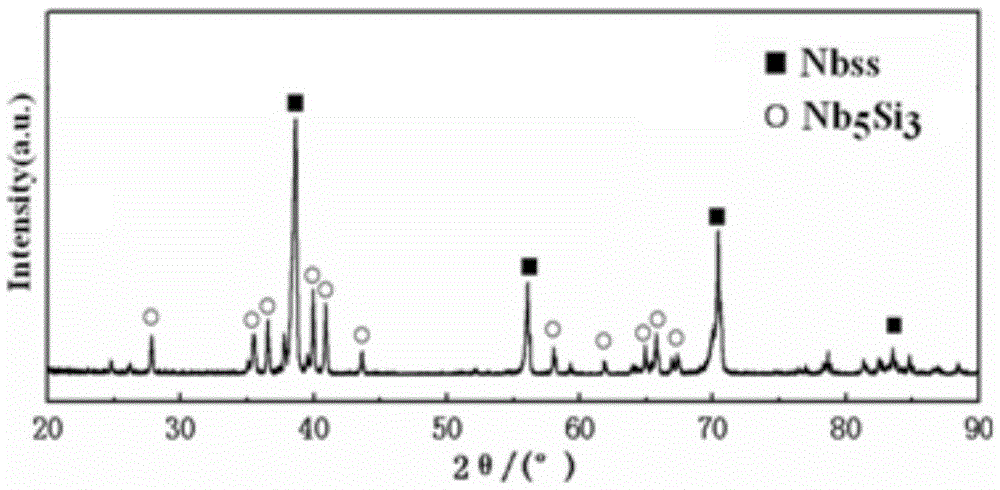

Embodiment 2

[0037] Using SLM technology to prepare Nb-16Si-22Ti-4Cr-2Al-2Hf (at.%, atomic percentage) super high temperature alloy: the SLM laser selective melting system used mainly includes: Nd-YAG laser, computer system for forming control, Powder feeding system and argon atmosphere protection device;

[0038] 1. Select Nb-16Si-22Ti-4Cr-2Al-2Hf pre-alloyed powder prepared by argon atomization method, the powder is spherical or nearly spherical, and the diameter is between 10 and 60 μm;

[0039] 2. According to the shape of the alloy parts to be processed, use the computer to establish a three-dimensional CAD model, and use the slicing software to perform layered slice discretization in the height direction of the model. Section profile information and scanning processing path, save multi-layer slice information as STL file, and transfer to SLM laser melting system;

[0040] 3. Put the powder into the forming cavity, and fix the Ti6Al4V forming substrate with a thickness of 10mm on the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com