Meso-porous silica, and catalyst for vapor phase carbonylation of propylene to butyraldehyde with meso-porous silica as carrier

A technology of mesoporous silica and catalyst, applied in silica, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc. The process is complex and other problems, to achieve the effect of solving the difficult separation of the catalytic system and the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1) Preparation of carrier mesoporous silica

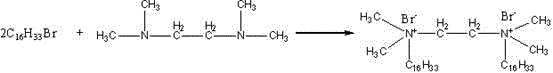

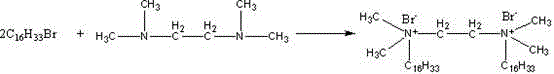

[0038] Take 45mL of hexadecane bromide (0.148 mol) and 30 mL of acetone into a three-necked flask, stir evenly with a magnetic force, place in a constant temperature water bath at 80°C, take 11mL of tetramethylethylenediamine (0.074 mol) in a constant pressure dropping funnel , drop by drop, heated to reflux for 48h. Cooled to room temperature to obtain a white powdery solid, washed 3 times with an appropriate amount of acetone, filtered and dried to obtain template C 16 -2-C 16 51.2 g.

[0039] The reaction equation is as follows:

[0040]

[0041] Template C was prepared by 8.4 g (0.012 mol) 16- 2-C 16 Dissolve in 150 mL of water, heat to 45°C, and stir evenly until it is completely dissolved, add 6.2 mL of tetraethyl orthosilicate (0.028 mol) to the obtained colloidal solution, add 0.1M NaOH solution dropwise to it to adjust the pH After fully stirring and mixing, the solution was placed in a high-temperature reac...

Embodiment 2

[0046] 1) Preparation of carrier mesoporous silica

[0047] Add 30 mL hexadecane bromide (0.098 mol) and 25 mL acetone into a three-necked flask, stir evenly with a magnetic force, place in a constant temperature water bath at 90°C, take 6.6 mL tetramethylethylenediamine (0.044 mol) and drop Liquid funnel, drop by drop and heated to reflux for 48h. Cooled to room temperature to obtain a white powdery solid, washed 3 times with an appropriate amount of acetone, filtered and dried to obtain template C 16 -2-C 16 32.7g.

[0048] Template C was prepared from 12.9 g 16 -2-C 16 (0.018 mol) was dissolved in 240 mL of water, heated to 45 °C, and stirred evenly until it was completely dissolved, and 11.2 mL of ethyl orthosilicate (0.050 mol) was added to the obtained colloidal solution, and 0.1M Adjust the pH of the NaOH solution to 5.5, stir and mix well, place the solution in a high-temperature reactor, and crystallize at 90°C for 12 hours; cool to room temperature and filter ...

Embodiment 3

[0053] 1) Preparation of carrier mesoporous silica

[0054] Take 40mL of hexadecane bromide (0.131 mol) and 30mL of acetone into a three-necked flask, stir evenly with a magnetic force, place in a constant temperature water bath at 85°C, take 9.3mL of tetramethylethylenediamine (0.063 mol) in a constant pressure dropping funnel , drop by drop and heated to reflux for 48h. Cooled to room temperature to obtain a white powdery solid, washed 3 times with an appropriate amount of acetone, filtered and dried to obtain template C 16 -2-C 16 42.7g.

[0055] Template C was prepared from 9.5 g 16 -2-C 16 (0.013 mol) was dissolved in 240mL of water, heated to 45°C, and stirred evenly until it was completely dissolved, and 7.3mL tetraethyl orthosilicate (0.033 mol) was added to the obtained colloidal solution, and 0.1M NaOH was added dropwise Adjust the pH of the solution to 5.0, stir and mix well, place the solution in a high-temperature reaction kettle, and crystallize at 95°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com