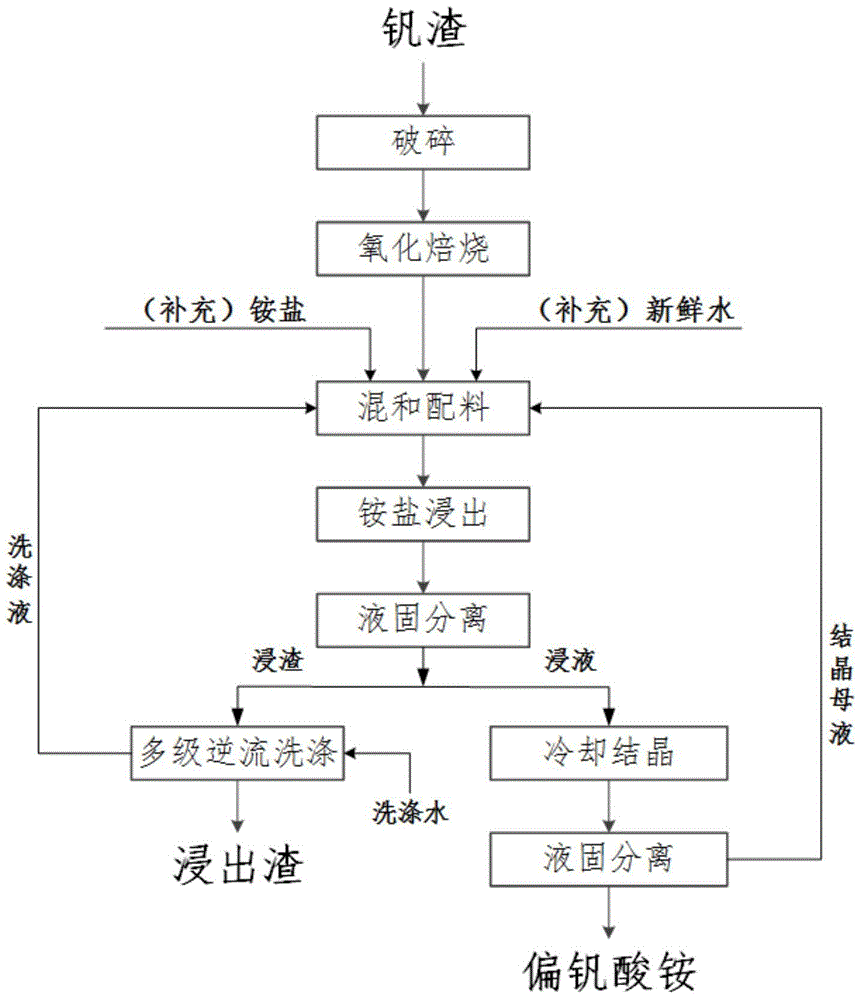

Method used for preparing ammonium metavanadate from vanadium slag via ammonium salt leaching

A technology of ammonium metavanadate and vanadium slag ammonium salt, which is applied in the field of non-ferrous metallurgy, can solve the problems of large amount of vanadium precipitation wastewater and Glauber's salt by-products, low purity of sodium vanadate products, and difficulty in acid wastewater treatment. The effect of simplifying the wastewater treatment process, low cost and short process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] (1) Crushing and grinding the vanadium slag to a particle size of less than 74 microns, pre-oxidizing at 800°C for 120 minutes, and opening the furnace door ajar during the roasting process to ensure that the vanadium slag is fully in contact with the air;

[0041](2) Take 40g of pre-oxidized vanadium slag, add it to 300g / L ammonium bicarbonate solution, and mix evenly. Among them, the ammonium bicarbonate solution has a volume of 200mL, and leaching reaction in an autoclave. The reaction is controlled at 150°C, and the reaction time is 3h , the pressure in the autoclave is 3.5MPa; after the reaction, the filter residue is washed twice with countercurrent water. During the washing process, the water consumption for each washing is 200mL, and the water temperature is 29°C;

[0042] (3) Cool the leaching solution obtained by filtration to 62° C. and filter to obtain ammonium metavanadate crystals.

[0043] After testing and calculation, the leaching rate of vanadium is 91...

Embodiment 2

[0045] (1) The vanadium slag is crushed and ground to a particle size of less than 74 microns, and pre-oxidized at 900°C for 60 minutes. During the roasting process, the furnace door is ajar to ensure that the vanadium slag is fully in contact with the air. .

[0046] (2) Take 40g of pre-oxidized vanadium slag, add it to 150g / L ammonium bicarbonate solution, mix well, and the volume of ammonium bicarbonate solution is 200mL, leaching reaction in an autoclave, control the reaction at 200°C, and the reaction time is 6h , the pressure in the autoclave is 4.1MPa. After the reaction, the filter residue is washed twice with countercurrent water. During the washing process, the water consumption for each washing is 200mL, and the water temperature is 34°C;

[0047] (3) Cool the leaching solution obtained by filtration to 51° C. and filter to obtain ammonium metavanadate crystals.

[0048] After testing and calculation, the leaching rate of vanadium is 90.89%, the leaching rate of si...

Embodiment 3

[0050] (1) Crushing and grinding the vanadium slag to a particle size of less than 74 microns, pre-oxidizing at 750°C for 180 minutes, and opening the furnace door ajar during the roasting process to ensure that the vanadium slag is fully in contact with the air;

[0051] (2) Take 40g of pre-oxidized vanadium slag, add it to 150g / L ammonium carbonate solution, and mix evenly. Among them, the ammonium bicarbonate solution has a volume of 200mL, and leaching reaction in an autoclave. The reaction is controlled at 150°C, and the reaction time is 6h. The pressure in the autoclave is 2MPa. After the reaction is completed, the filter residue is washed twice with countercurrent water. During the washing process, the water consumption for each washing is 200mL, and the water temperature is 23°C;

[0052] (3) Cool the leaching solution obtained by filtration to 55° C. and filter to obtain ammonium metavanadate crystals.

[0053] After testing and calculation, the leaching rate of vanad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com