Method for measuring isostatic pressure resistance of hollow glass beads

A technology of hollow glass microbeads and measuring method, which is applied in the direction of using stable tension/pressure test material strength, measuring device, specific gravity measurement, etc., can solve the problems of deviation of test results and high test results, and avoid corrosion. , High test accuracy and the effect of reducing errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

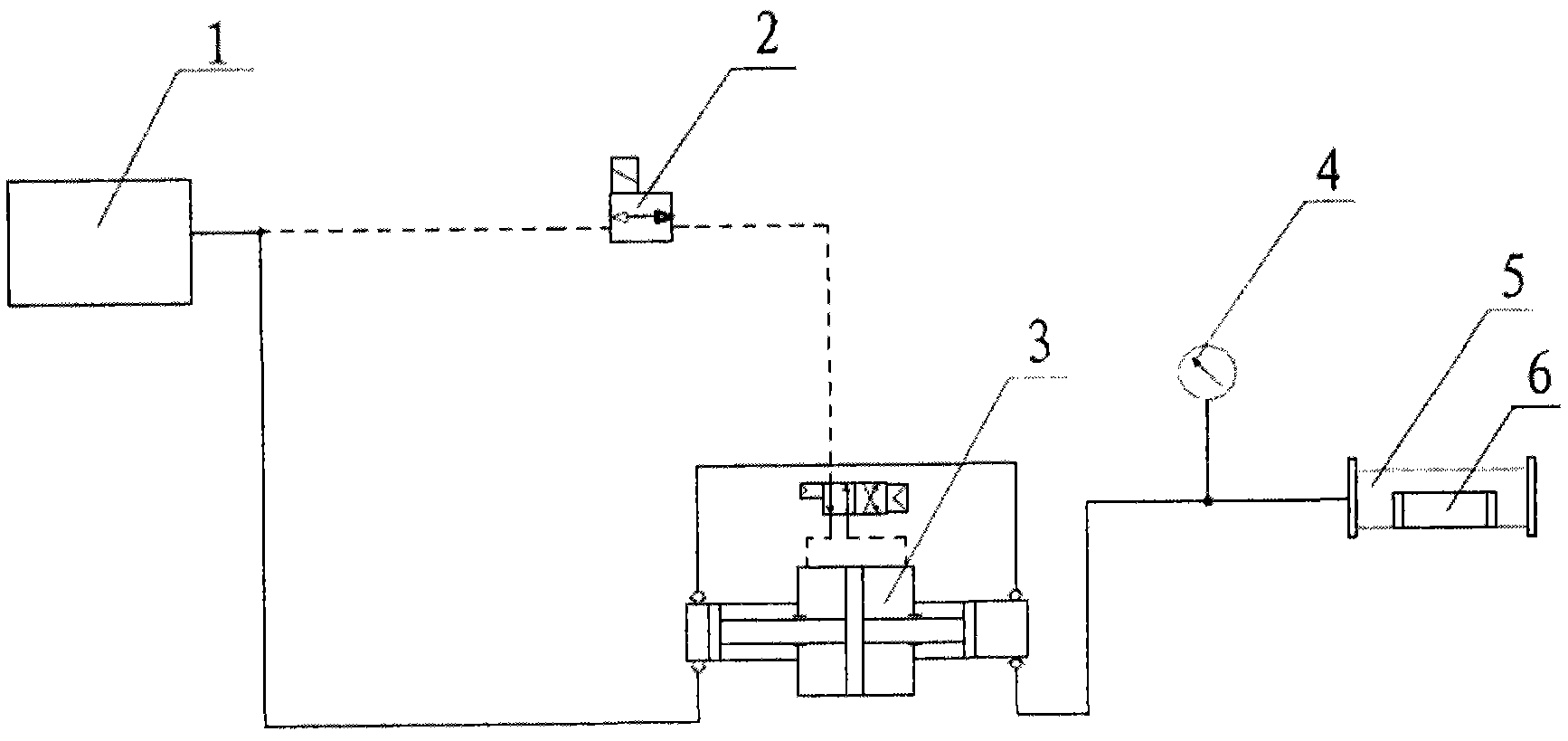

Method used

Image

Examples

Embodiment 1

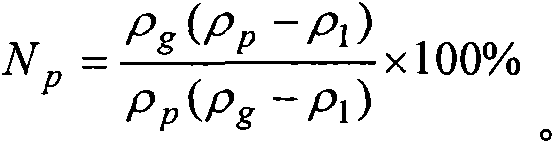

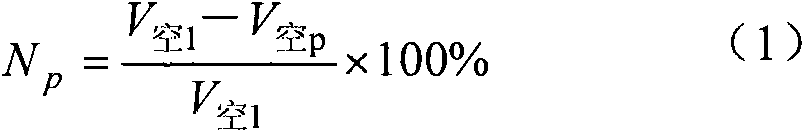

[0052] The hollow glass microsphere samples of the same batch were selected, and the samples were baked until dry for use. Take out 1.5g hollow glass microsphere sample (apparent particle density is at 0.10-0.20g / cm 3 between) into the sample compartment of the true density tester, and use the true density tester to measure the density ρ of the sample 1 0.14g / cm 3 . Take out 25g hollow glass microsphere sample, grind three times with a corundum mortar, grind for 20 minutes each time, fully pulverize the sample, use a true density tester to measure the density ρ of the ground sample g 2.47g / cm 3 . Take out 1.5g hollow glass microsphere sample and put it into a specific sample cell. Increase the pressure for 1 minute to the isostatic pressure of 2MPa, open the pressure relief valve immediately, and after returning to normal pressure, open the high-pressure test chamber, take out the sample pool, take the compressed sample out of the sample pool, and use a true density teste...

Embodiment 2

[0056] The hollow glass microsphere samples of the same batch were selected, and the samples were baked until dry for use. Take out 1.5g hollow glass microsphere sample (apparent particle density is at 0.10-0.20g / cm 3 between) into the sample compartment of the true density tester, and use the true density tester to measure the density ρ of the sample 1 0.16g / cm 3 . Take out 25g of hollow glass microsphere samples, mechanically crush them three times with a pressure of 50 MPa, keep the pressure for 10 minutes each time, fully pulverize the samples, and use a true density tester to measure the density ρ of the crushed samples g 2.50g / cm 3 . Take out 1.5g hollow glass microsphere sample and put it into a specific sample cell. Boost the pressure for 2 minutes to the isostatic pressure of 5MPa, maintain the pressure of 5MPa for 1 minute, open the pressure relief valve, after returning to normal pressure, open the high pressure test chamber, take out the sample pool, take the ...

Embodiment 3

[0058] The hollow glass microsphere samples of the same batch were selected, and the samples were baked until dry for use. Take out 2.0g hollow glass microsphere sample (apparent particle density is at 0.20-0.30g / cm 3 between) into the sample compartment of the true density tester, and use the true density tester to measure the density ρ of the sample 1 0.25g / cm 3 . Take out 25g hollow glass microsphere sample, grind three times with a ceramic mortar, grind for 30 minutes each time, fully pulverize the sample, use the true density tester to measure the density ρ of the sample after grinding g 2.48g / cm 3 . Take out 2.0g of hollow glass microsphere samples and put them into a specific sample cell. The volume is subject to the loosely filled sample cell. Put the sample cell into a specific high-pressure test chamber, close the high-pressure test chamber, and use a booster to introduce argon gas , boost the pressure for 5 minutes to isostatic pressure of 10MPa, maintain the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com