Preparing method for high-temperature resistant metal/ceramic composite heating unit material

A ceramic composite and heating element technology, which is applied in the direction of heating element materials, can solve the problems of low heating efficiency and short life of heating element materials, and achieve the effects of high temperature resistance, long life and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Step 1, take Al 2 o 3 30ml of ceramic powder, 5ml of polyvinyl alcohol, 65ml of distilled water, fully mixed, degassed and sieved to obtain Al 2 o 3 Casting slurry; Al 2 o 3 The slurry was cast into sheet-like Al with a thickness of 500 μm 2 o 3 green body;

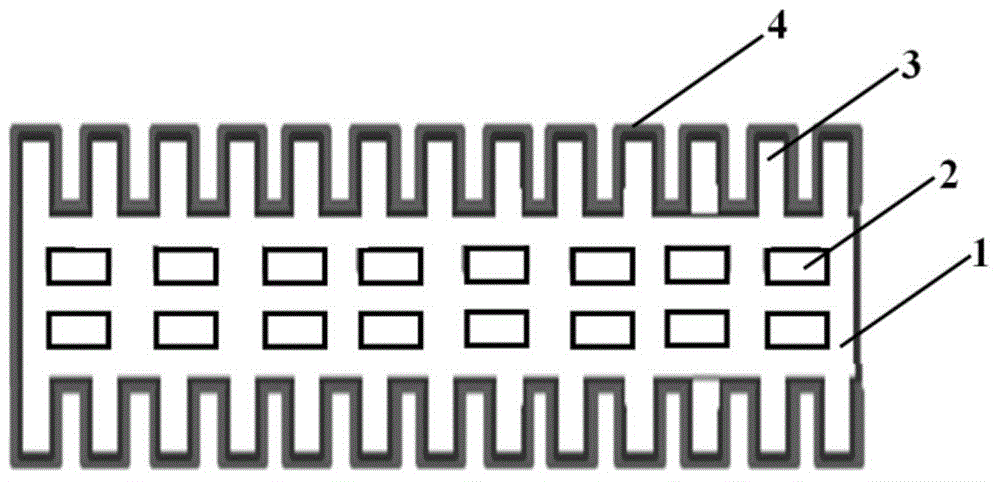

[0056] Step 2, take 50ml of NiCr alloy powder, 50ml of ethyl cellulose solution, fully mix, vacuum degas and sieve to obtain the NiCr alloy slurry for screen printing; take sheet Al 2 o 3 Green body, the NiCr alloy paste is printed on the sheet Al by a screen printing machine 2 o 3 On the surface of one side of the green body, the shape of the printed NiCr alloy is S-shaped, and the thickness is 200 μm. After drying at 25 ° C, the sheet-type Al 2 o 3 / NiCr composite green body;

[0057] Step 3, the flake Al 2 o 3 / NiCr composite green bodies are laminated in the order that the side with the printed NiCr shape faces up, the number of laminated layers is 2 layers, and a layer of sheet Al is placed on th...

Embodiment 2

[0062] Step 1, take ZrO 2 Ceramic powder 35ml, carboxymethyl cellulose 8ml, distilled water 57ml, fully mixed, vacuum degassed and sieved to obtain ZrO 2 Casting slurry; the ZrO 2 The slurry was cast into sheet-like ZrO with a thickness of 400 μm 2 green body;

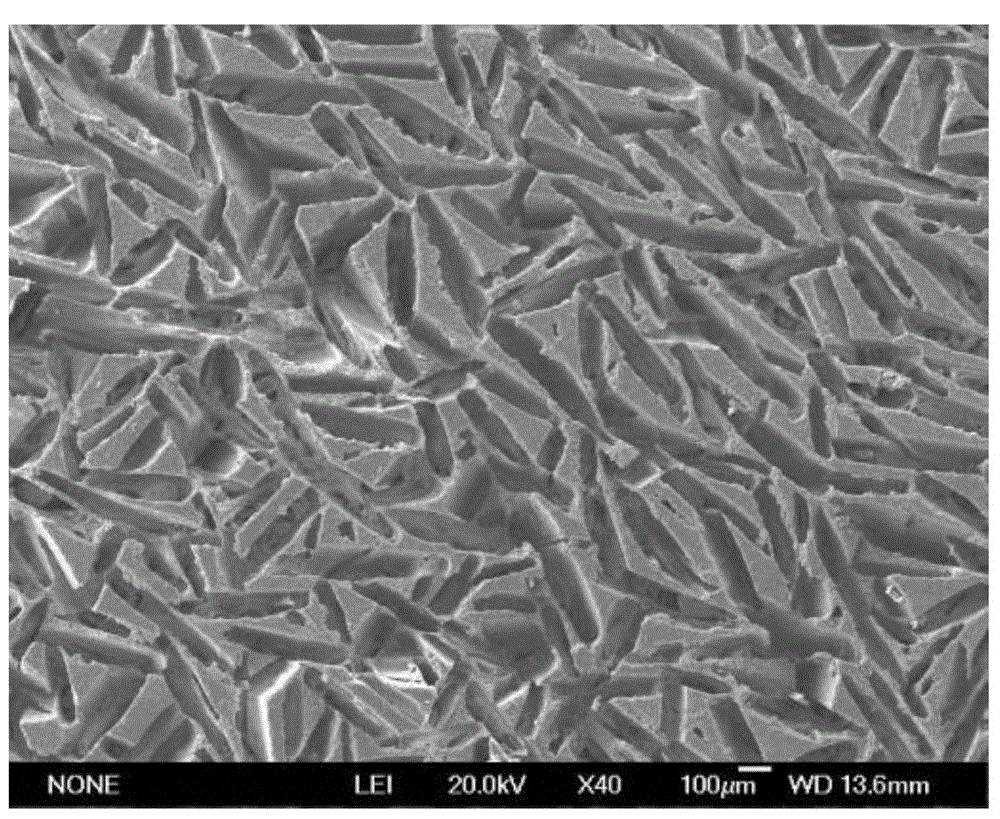

[0063] Step 2, take Ni powder 70ml, castor oil and rosin turpentine mixture 30ml, vacuum degass and sieve after fully mixing, obtain the Ni slurry for screen printing; Take sheet ZrO 2 Green body, the Ni paste is printed on the sheet ZrO by a screen printing machine 2 On the surface of one side of the green body, the printed Ni is in the shape of a mesh, with a thickness of 50 μm, and after drying at 40 ° C, the sheet ZrO 2 / Ni composite green body;

[0064] Step 3, the chip ZrO 2 / Ni composite green bodies are stacked in the order that the side with the Ni shape printed on them faces up, the number of stacks is 3 layers, and a layer of sheet ZrO is placed on the top layer. 2 The green body is then heat-sealed i...

Embodiment 3

[0069] Step 1, take SiO 2 40ml of ceramic powder, 12ml of polyvinyl alcohol, 48ml of distilled water, fully mixed, vacuum degassed and sieved to obtain SiO 2 Casting slurry; SiO 2 The slurry was cast into sheet SiO with a thickness of 600 μm 2 green body;

[0070] Take 30ml of molybdenum-manganese alloy powder and 70ml of terpineol, mix well, vacuum degas and sieve to obtain molybdenum-manganese alloy slurry for screen printing; take sheet SiO 2 Green body, the molybdenum-manganese alloy paste is printed on the sheet SiO by a screen printing machine 2 On the surface of one side of the green body, the shape of the printed molybdenum-manganese alloy is S-shaped, with a thickness of 100 μm. After drying at 50 ° C, the sheet SiO 2 / Molybdenum-manganese composite green body;

[0071] Step 3, the chip SiO 2 / Molybdenum-manganese composite green bodies are stacked in order with the side printed with the shape of molybdenum-manganese facing up, the number of stacks is 4 layers, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com