Chitosan-nano-silver wound dressing and preparation method thereof

A technology of wound dressing and chitosan, which is applied in the field of chitosan-nano silver wound dressing and its preparation, can solve the problems of affecting wound healing, stimulating wound, liquid penetration, etc., and achieve excellent wound repair ability, growth promotion, size uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

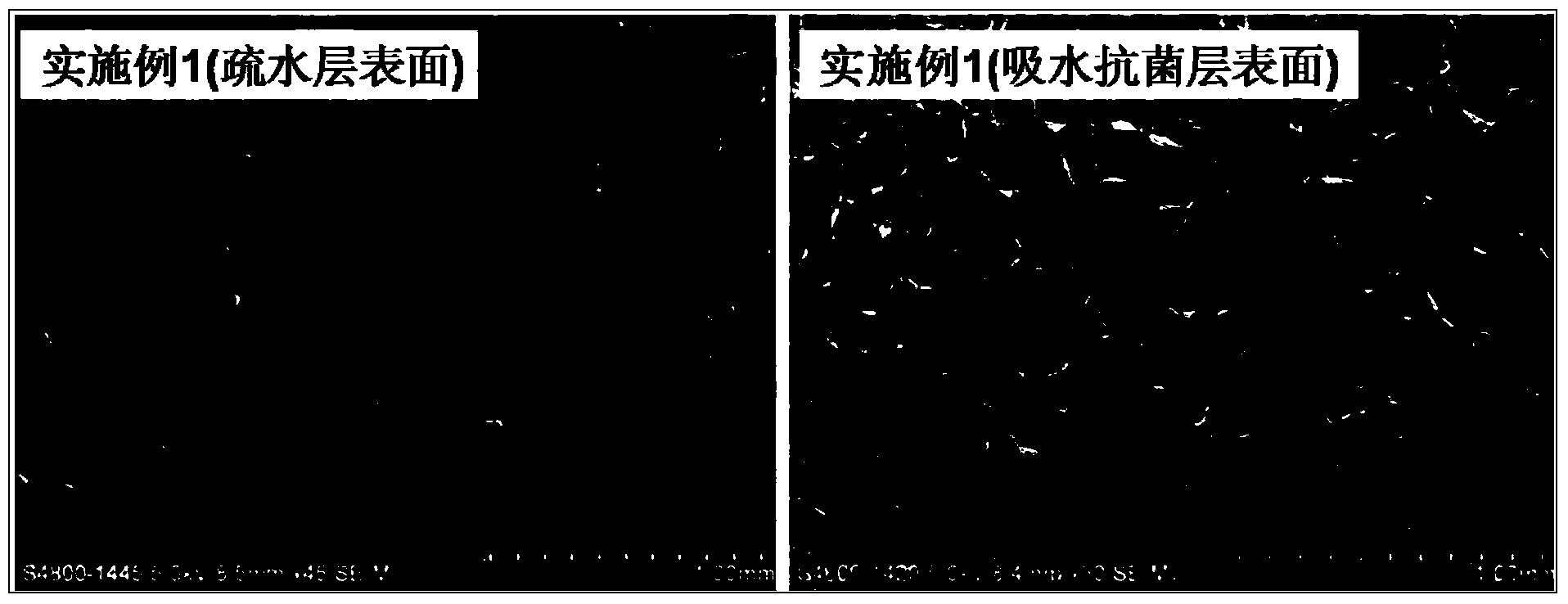

Embodiment 1

[0038] Preparation of spongy chitosan: Weigh 0.8g chitosan (deacetylation degree is 70%, viscosity is 100cPa s), dissolve it in 50mL acetic acid solution with a concentration of 0.5wt%, and the obtained shell The polysaccharide acetic acid solution was poured into a glass petri dish and placed in a refrigerator for pre-freezing at -20°C for 12h. Then place it in a vacuum freeze dryer for freeze-drying treatment, wherein the parameters of the freeze dryer are: the cold trap temperature is -40°C, the vacuum degree is 10Pa, and the freezing time is 18 hours. Subsequent soaking treatment with 1.0 mol / L sodium hydroxide solution for 2 hours, and repeated washing with deionized water until neutral spongy chitosan was obtained.

[0039] Preparation of nano-silver sol: Weigh 1.2g polyvinylpyrrolidone (PVP, weight-average molecular weight Mw=55,000), dissolve it in 60mL deionized water, add dropwise 6mL silver nitrate aqueous solution with a concentration of 0.1mol / L, stir for 30 minut...

Embodiment 2

[0047] Preparation of spongy chitosan: Weigh 1.0g chitosan (deacetylation degree is 95%, viscosity is 100cPa s), dissolve in 50mL acetic acid solution with a concentration of 1wt%, and dissolve the obtained chitosan The sugar-acetic acid solution was poured into a glass petri dish and placed in a refrigerator for pre-freezing at -18°C for 12 hours. Then place it in a vacuum freeze dryer for freeze-drying treatment, wherein the parameters of the freeze dryer are: cold trap temperature-55°C, vacuum degree 4Pa, and freezing time of 24 hours. Subsequent soaking treatment with 2.0 mol / L sodium hydroxide solution for 2 hours, and repeated washing with deionized water until neutral spongy chitosan is obtained.

[0048] Preparation of nano-silver sol: Weigh 0.05g polyvinylpyrrolidone (PVP, weight average molecular weight Mw=55,000), dissolve it in 50mL deionized water, add dropwise 2.5mL silver nitrate aqueous solution with a concentration of 0.1mol / L, and stir for 30 minutes Slowly ...

Embodiment 3

[0055] Preparation of spongy chitosan: weigh 1.5g chitosan (deacetylation degree is 100%, viscosity is 200cPa s), dissolve in 50mL acetic acid solution with a concentration of 1.5wt%, and the obtained shell The polysaccharide acetic acid solution was poured into a glass petri dish and placed in a refrigerator for pre-freezing at -22°C for 8 hours. Then place it in a vacuum freeze dryer for freeze-drying treatment, wherein the parameters of the freeze dryer are: cold trap temperature-58°C, vacuum degree 8Pa, and freezing time 16h. Subsequent soaking treatment with 1.2 mol / L ammonia solution for 2 hours, and repeated washing with deionized water until neutral spongy chitosan was obtained.

[0056] Preparation of nano-silver sol: Weigh 0.5g polyvinylpyrrolidone (PVP, weight-average molecular weight Mw=55,000), dissolve it in 45mL deionized water, add dropwise 2.5mL silver nitrate aqueous solution with a concentration of 0.2mol / L, and stir for 30 minutes Slowly add 0.1mol / L sodiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com