Nano-structure CoSx/C cathode electro-catalytic material and preparation method thereof

An electrocatalytic material and nanostructure technology, applied in chemical instruments and methods, physical/chemical process catalysts, structural parts, etc., can solve the problems of small particle size and narrow distribution, and achieve inhibition of agglomeration, good performance, and particle size. Evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

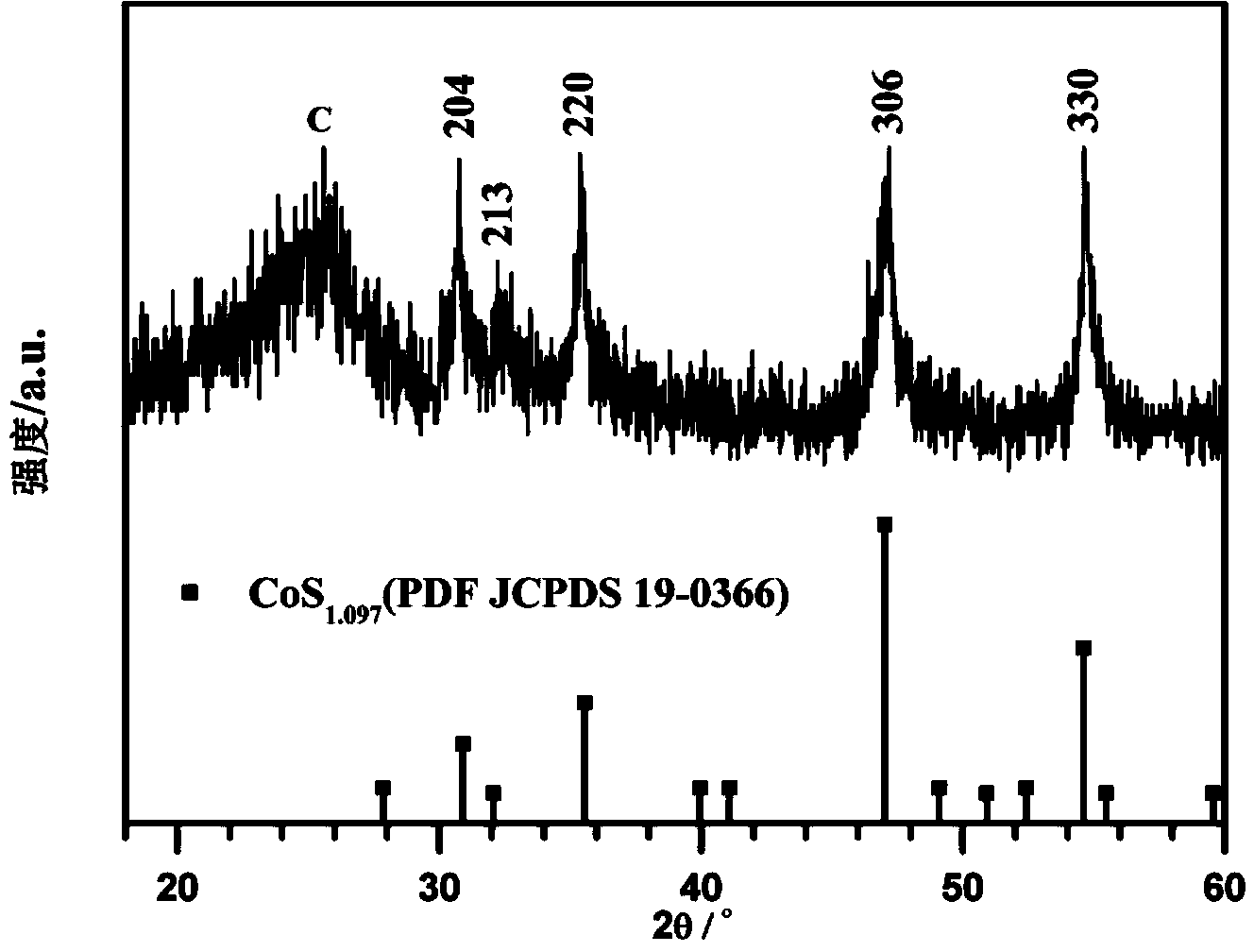

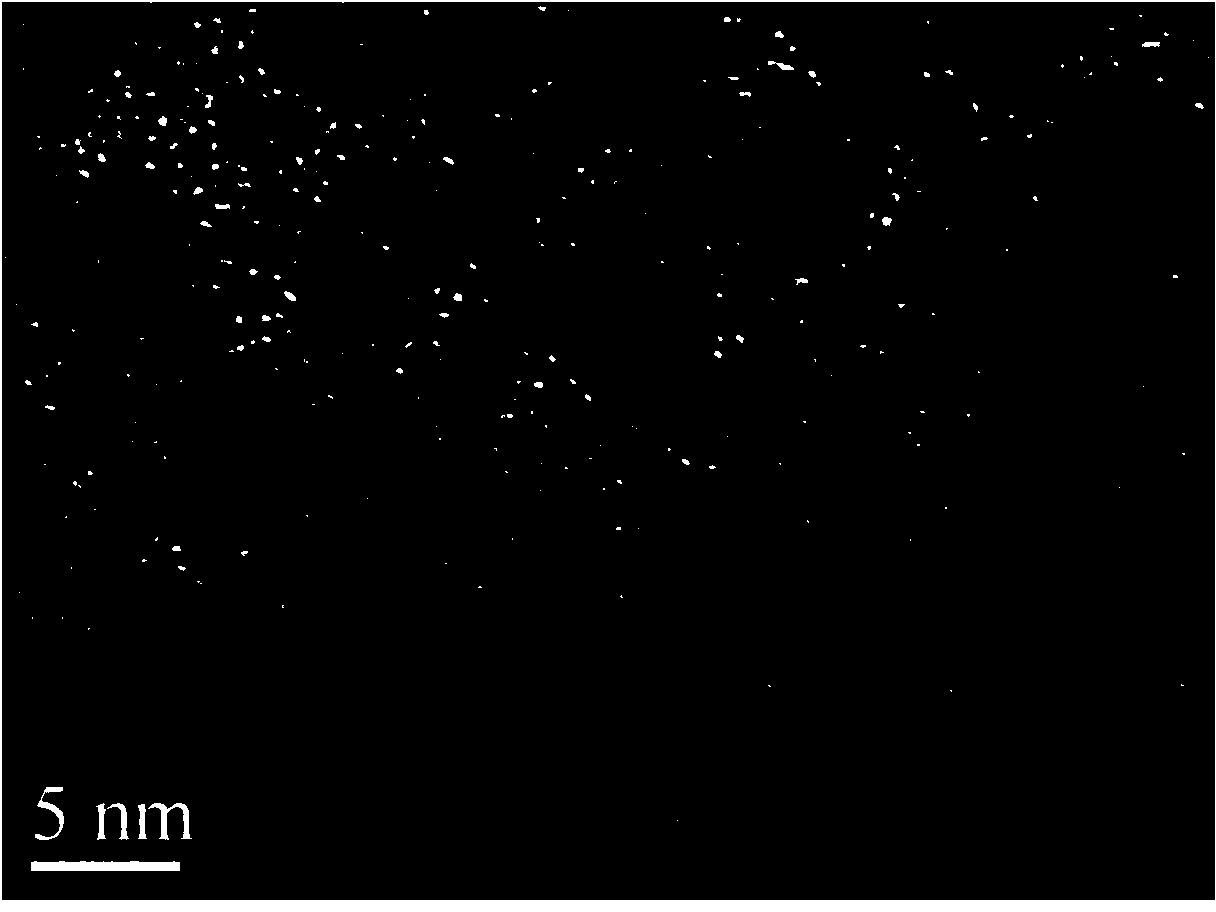

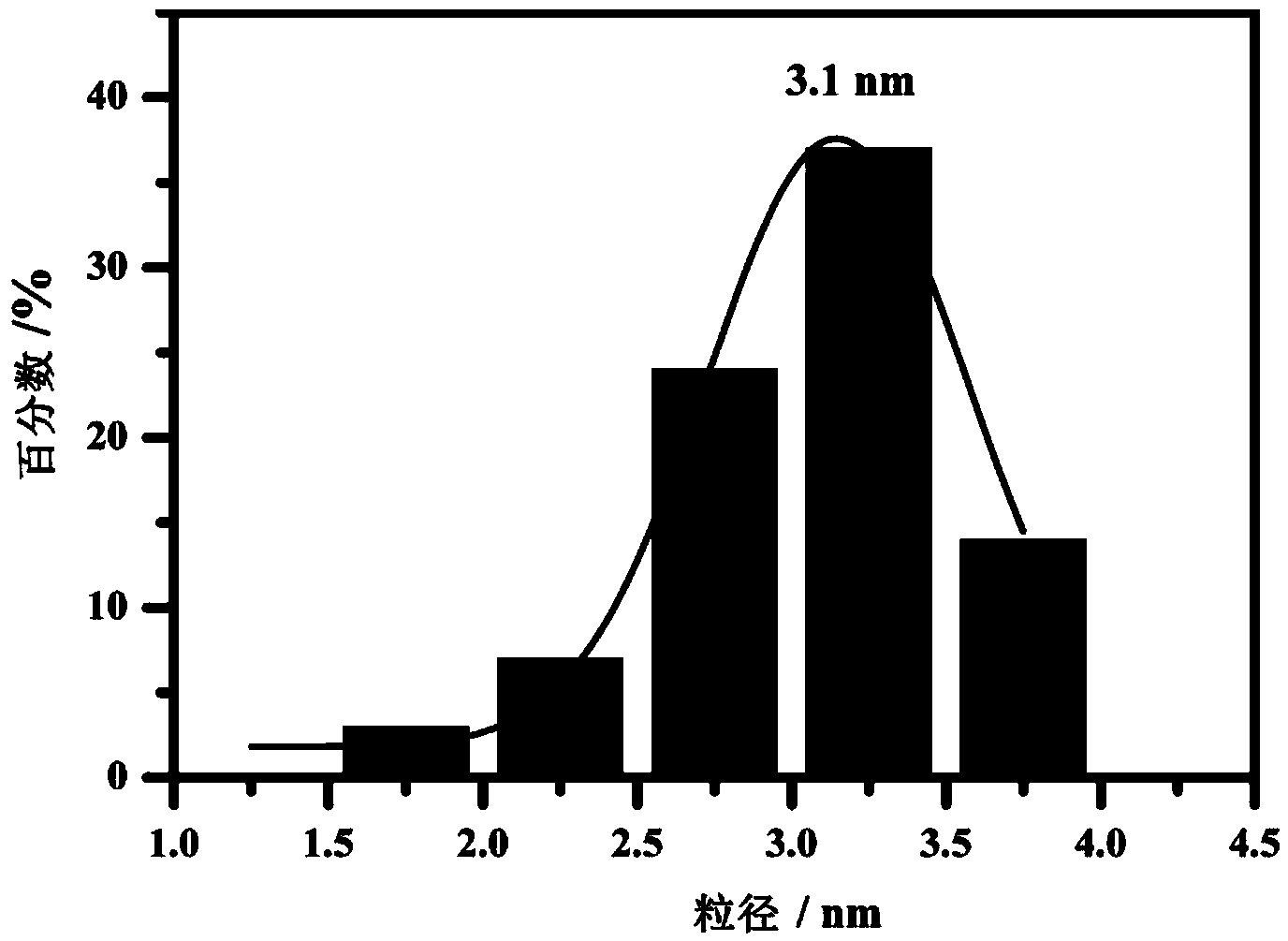

[0024] Weigh 0.23g Co(NO 3 ) 2 ·6H 2 O and 0.3g of conductive carbon black are dissolved in 80mL of absolute ethanol to form a solution with a cobalt salt concentration of 0.01mol / L;

[0025] Weigh 0.187g Na 2 Dissolve S in 80mL of absolute ethanol to make S with a concentration of 0.03mol / L 2- solution; the two solutions were simultaneously poured into a rotating liquid film reactor and quickly mixed for 30 seconds; the rotational speed of the liquid film reactor was 4500 rpm, and the gap size between the stator and the rotor was 17 μm.

[0026] Transfer the nucleated slurry to a high-pressure reactor, and crystallize and grow at a constant temperature of 80°C for 8 hours; the reaction slurry is centrifuged and washed with deionized water for more than 5 times, and finally washed once with absolute ethanol, and the filter cake is dried in an oven at 60 Dry at ~100°C for 12 hours to obtain the final product.

[0027] The obtained CoS x / C for electrochemical performance ...

Embodiment 2

[0036] Weigh 0.19g CoCl 2 ·6H 2 O and 0.2g of carbon nanotubes were dissolved in 80mL of absolute ethanol to form a solution with a cobalt salt concentration of 0.01mol / L; weigh 0.164g (NH 4 ) 2 Dissolve S in 80mL of absolute ethanol to make S with a concentration of 0.03mol / L 2- solution; two solutions are simultaneously poured into a rotating liquid film reactor and quickly mixed, nucleating for 30 seconds, the rotating speed of the liquid film reactor is 5000rpm, and the gap size between the stator and the rotor is 17 μm; the slurry after nucleation is transferred to In a high-pressure reactor, crystallize and grow at a constant temperature of 100°C for 6 hours; the reaction slurry is centrifugally washed with deionized water for more than 5 times, and finally washed with absolute ethanol once, and the filter cake is dried in an oven at 60-100°C for 12 hours The final product, CoS x The average particle size of the particles is 2.5 nm.

Embodiment 3

[0038] Weigh 0.22g CoSO 4 ·7H 2 O and 0.3g graphene are dissolved in 80mL absolute ethanol, are made into the solution that cobalt salt concentration is 0.01mol / L; Weigh 0.312g Na 2 Dissolve S in 80mL of absolute ethanol to prepare S with a concentration of 0.05mol / L 2- solution; two solutions are simultaneously poured into a rotating liquid film reactor and quickly mixed, and the nucleation is 60 seconds. The rotating speed of the liquid film reactor is 5000rpm, and the gap size between the stator and the rotor is 15 μm; In a high-pressure reactor, crystallize and grow at a constant temperature of 80°C for 8 hours; the reaction slurry is centrifugally washed with deionized water for more than 5 times, and finally washed once with absolute ethanol, and the filter cake is dried in an oven at 60-100°C for 12 hours The final product, CoS x The average particle size of the particles was 1.3 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com