Waterproof and moisture permeable composite membrane and preparation method thereof

A waterproof and moisture-permeable, composite membrane technology, applied in the field of textiles, can solve the problems of uneven distribution of micropores and complex processes in composite membranes, and achieve the effects of good chemical gas particle performance, complex operation, and excellent high and low temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

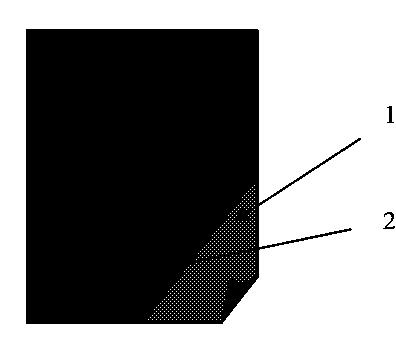

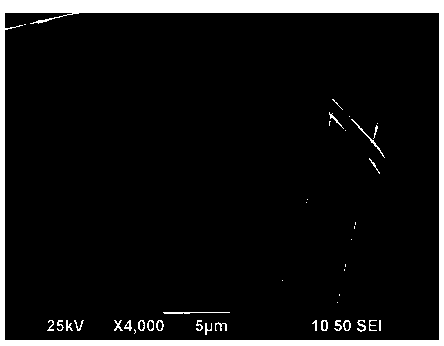

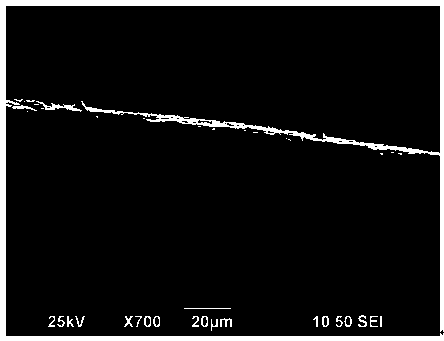

[0039] The waterproof and moisture-permeable composite membrane of this embodiment includes a hydrophobic membrane 2 and a hydrophilic membrane 1, the hydrophobic membrane 2 is made by electrospinning on the surface of the hydrophilic membrane 1, and the main component of the hydrophobic membrane 2 is polyvinylidene fluoride , the hydrophobic film 2 is doped with acrylate rubber accounting for 2.4% of the mass of polyvinylidene fluoride, the thickness of the hydrophobic film 2 is 50 μm; the hydrophilic film 1 is thermoplastic polyester, the thickness of the hydrophilic film 1 is 15 μm, electrospinning The nanofiber diameter is 1000nm.

[0040] The preparation method of the waterproof and moisture-permeable composite membrane of this embodiment, the steps are as follows:

[0041] (1) Dissolve polyvinylidene fluoride with an intrinsic viscosity of 33.0mpa·S in a mixture of N,N-dimethylacetamide and acetone with a volume ratio of 1:1 to make a solution with a concentration of 11w...

Embodiment 2

[0045] The waterproof and moisture-permeable composite membrane of this embodiment includes a hydrophobic membrane and a hydrophilic membrane. The hydrophobic membrane is made by electrostatic spinning on the surface of the hydrophilic membrane. The main component of the hydrophobic membrane is polytetrafluoroethylene, and the hydrophobic membrane is mixed with Mixed with acrylate rubber accounting for 9.6% of the mass of PTFE, the thickness of the hydrophobic film is 150 μm; the hydrophilic film is thermoplastic polyester, the thickness of the hydrophilic film is 20 μm, and the diameter of the electrospun nanofiber is 4000 nm.

[0046] The preparation method of the waterproof and moisture-permeable composite membrane of this embodiment, the steps are as follows:

[0047] (1) Dissolve polytetrafluoroethylene with an intrinsic viscosity of 41.0mpa·S in a mixture of N,N-dimethylacetamide and acetone with a volume ratio of 2:1 to make a solution with a concentration of 17wt%. Und...

Embodiment 3

[0051] The waterproof and moisture-permeable composite membrane of this embodiment includes a hydrophobic membrane and a hydrophilic membrane. The hydrophobic membrane is made by electrospinning on the surface of the hydrophilic membrane. The main component of the hydrophobic membrane is polyvinylidene fluoride, and the hydrophobic membrane is mixed with Mixed with acrylate rubber accounting for 7.8% of the mass of polyvinylidene fluoride, the thickness of the hydrophobic film is 100 μm; the hydrophilic film is thermoplastic polyester, the thickness of the hydrophilic film is 15 μm, and the diameter of the electrospun nanofiber is 2000 nm.

[0052] The preparation method of the waterproof and moisture-permeable composite membrane of this embodiment, the steps are as follows:

[0053] (1) Dissolve polyvinylidene fluoride with an intrinsic viscosity of 35.0mpa·S in a mixture of N,N-dimethylacetamide and acetone with a volume ratio of 4:1 to make a solution with a concentration of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com