Method of recovering phosphorus

A technology of hydrated calcium silicate and crystals, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve problems such as increased operating costs, increased operating costs, and blockages , to achieve the effect of avoiding the increase of sludge volume, avoiding waste and reducing by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 The recovery of phosphorus in phosphorus-containing wastewater

[0037] 10L of phosphorus-containing wastewater was collected; the phosphorus-containing wastewater came from the effluent of the secondary sedimentation tank of a certain urban sewage treatment plant in Chongqing, and the phosphorus content in the wastewater was measured to be 5mg / L.

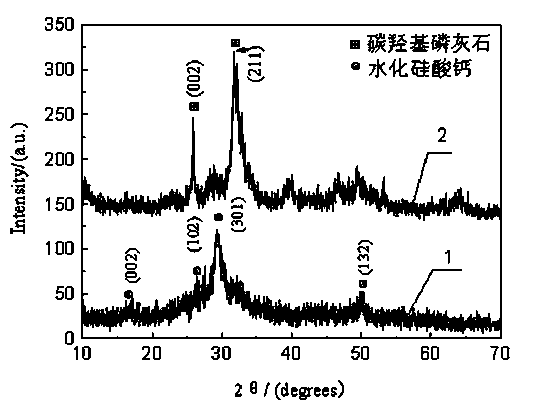

[0038] Take phosphorus-containing wastewater (calculated by the mass of phosphorus) and the excess interplanar spacing is 1.3nm, which has an X-ray diffraction absorption peak at 2θ=30.55°, and the infrared characteristic peak is: δ(Si-O-Si) 455cm -1 , V δ (Si-O-Si) 652 cm -1 , V(Si-O)Q 1 816cm -1 , V(Si-O)Q 2 970cm -1 After mixing the excess calcium silicate hydrate crystals with a calcium-silicon molar ratio of 10g, they are mixed with excess carbonate (carbonates include sodium carbonate, sodium bicarbonate or calcium bicarbonate.) Mix, collect 100 ~ 140μm 1.04g of precipitate; 8.97g of precipitate wit...

Embodiment 2

[0043] Example 2 Recovery of Phosphorus in Phosphorous Wastewater

[0044] 10L of phosphorus-containing wastewater was collected; the phosphorus-containing wastewater came from the effluent of an anaerobic phosphorus release tank of a certain urban sewage treatment plant in Chongqing, and the phosphorus content in the wastewater was measured to be 10mg / L.

[0045] Take phosphorus-containing wastewater (calculated by the mass of phosphorus) and the excess interplanar spacing is 1.3nm, which has an X-ray diffraction absorption peak at 2θ=30.55°, and the infrared characteristic peak is: δ(Si-O-Si) 455cm -1 , V δ (Si-O-Si) 652 cm -1 , V(Si-O)Q 1 816cm -1 , V(Si-O)Q 2 970cm -1 After mixing the excess calcium silicate hydrate crystals with a calcium-silicon molar ratio of 10g, they are mixed with excess carbonate (carbonates include sodium carbonate, sodium bicarbonate or calcium bicarbonate.) Mix, collect 100 ~ 140μm 1.08g of precipitate; 3.94g of precipitate with a parti...

Embodiment 3

[0049] Example 3 Recovery of Phosphorus in Phosphorous Wastewater

[0050] 10L of phosphorus-containing wastewater was collected; the phosphorus-containing wastewater came from the effluent of an anaerobic phosphorus release tank of a certain urban sewage treatment plant in Chongqing, and the phosphorus content in the wastewater was measured to be 20mg / L.

[0051] Take phosphorus-containing wastewater (calculated by the mass of phosphorus) and the excess interplanar spacing is 1.3nm, which has an X-ray diffraction absorption peak at 2θ=30.55°, and the infrared characteristic peak is: δ(Si-O-Si) 455cm -1 , V δ (Si-O-Si) 652 cm -1 , V(Si-O)Q 1 816cm -1 , V(Si-O)Q 2 970cm -1 After mixing the excess calcium silicate hydrate crystals with a calcium-silicon molar ratio of 10g, they are mixed with excess carbonate (carbonates include sodium carbonate, sodium bicarbonate or calcium bicarbonate.) Mix, collect 100 ~ 140μm 1.18g of precipitate; 8.95g of precipitate with a parti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| lattice spacing | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com