Aluminum silicate yellow-green fluorescent powder for LED and preparation method thereof

A yellow-green phosphor, aluminosilicate technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of less aluminosilicate-based phosphors, and achieve easy industrial production, cheap and easy-to-obtain raw materials, and luminescence. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

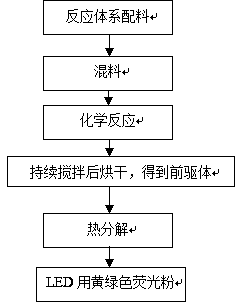

Method used

Image

Examples

Embodiment example 1

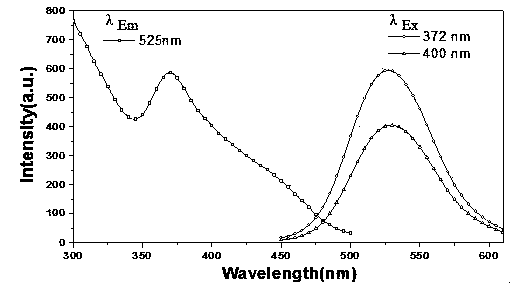

[0021] According to the chemical formula Ca 1.99 AlMg 0.5 Si 1.5 O- 7 :0.01Eu 2+ Weigh CaCO 3 (A.R.)1.99mol, Al(NO 3 ) 3 ·9H 2 O (A.R.) 1mol, Mg (NO 3 ) 2 ·6H 2 O (A.R.) 0.5mol, nano-SiO 2 1.5mol, Eu 2 O 3 (99.99%) 0.005mol; then weigh the surfactant polyethylene glycol of 0.8wt% of the total mass of the above drugs; prepare the precipitant NH 4 HCO 3 solution, the concentration is 3mol / L; the Eu will be weighed 2 O 3 Dissolve with an appropriate amount of nitric acid, add an appropriate amount of deionized water, and then heat to 50 °C for water bath treatment; add CaCO to the above solution 3 , Al(NO 3 ) 3 ·9H 2 O, Mg (NO 3 ) 2 ·6H 2 O, nano-SiO 2 , polyethylene glycol, stir at the same time, add precipitating agent dropwise, adjust PH=9, continue stirring for 1 hour; directly dry to obtain fluffy precursor; place the precursor in an atmosphere furnace with hydrogen for calcination, and the calcination temperature At 1150°C, and the calcination time ...

Embodiment example 2

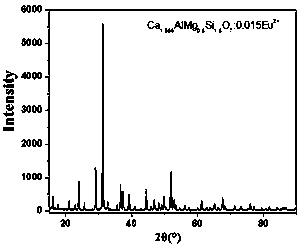

[0023] According to the chemical formula Ca 1.985 AlMg 0.5 Si 1.5 O- 7 :0.015Eu 2+ Weigh CaCO 3 (A.R.)1.985mol, Al(NO 3 ) 3 ·9H 2 O(A.R.) 1mol, Mg(NO 3 ) 2 ·6H 2 O(A.R.) 0.5mol, nano-SiO 2 1.5mol, Eu 2 O 3 (99.99%) 0.0075mol; then weigh the surfactant polyethylene glycol of 0.6wt% of the total mass of the above drugs; prepare a precipitant (NH 4 ) 2 C 2 O 4 +NH 3 ·H 2 O solution with a concentration of 3 mol / L; the weighed Eu 2 O 3 Dissolve with an appropriate amount of nitric acid, add an appropriate amount of deionized water, and then heat to 45°C for water bath treatment; add CaCO to the above solution 3 , Al(NO 3 ) 3 ·9H 2 O, Mg (NO 3 ) 2 ·6H 2 O, nano-SiO 2 , polyethylene glycol, stir at the same time, add precipitant dropwise, adjust PH=9, continue stirring for 2 hours; directly dry to obtain fluffy precursor; put the precursor in a mixed gas of nitrogen and hydrogen (H2 and N 2 ) in an atmosphere furnace, the calcination temperature is 1200...

Embodiment example 3

[0025] According to the chemical formula Ca 1.99 AlMg 0.5 Si 1.5 O- 7 :0.01Eu 2+ Weigh CaCl 2 (A.R.)1.99mol, Al(NO 3 ) 3 ·9H 2 O(A.R.) 1mol, MgCl 2 (A.R.) 0.5mol, nano-SiO 2 1.5mol, Eu 2 O 3 (99.99%) 0.005mol; then weigh the surfactant polyethylene glycol with 0.4wt% of the total mass of the above drugs; prepare a precipitant (NH 4 ) 2 CO 3 solution, the concentration is 2mol / L; the Eu will be weighed 2 O 3 Dissolve with an appropriate amount of hydrochloric acid, add an appropriate amount of deionized water, and heat to 40 °C for water bath treatment; add CaCl to the above solution 2 , Al(NO 3 ) 3 ·9H 2 O, MgCl 2 (A.R.), nano-SiO 2 , polyethylene glycol, stir at the same time, add precipitating agent dropwise, adjust PH=8, continue to stir for 3 hours; directly dry to obtain fluffy precursor; place the precursor in a stream of hydrogen (H 2 ) in an atmosphere furnace, the calcination temperature is 1250°C, and the calcination time is 3 hours, to obtain t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com