Device for gathering liquid drops in metal slag by adding pulsed electric field

A pulsed electric field and metal droplet technology, applied in the improvement of process efficiency, recycling technology and other directions, can solve the problem that the separation efficiency of slag and metal droplets is difficult to control, lacks effective means of slag gold separation and recovery of metals, and is not suitable for industrial production. Application and other issues, to achieve the effect of simple structure, strong slag corrosion resistance, and time saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

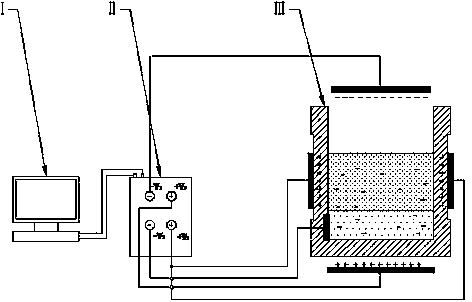

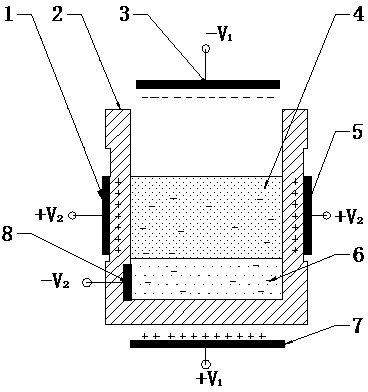

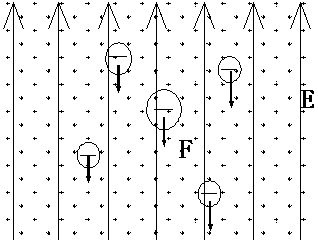

[0036] In this example, see Figure 1 ~ Figure 3 , a device for gathering droplets in molten metal slag by applying an external pulse electric field. It is composed of a controller I, a pulse power supply II and a reaction furnace III. A series of electrode plates are laid and inlaid on 2, and each electrode plate is correspondingly connected to the electrode end of the pulse power supply II to form an electric field generation system, so that the slag-gold system 4 in the reaction furnace III is under the action of the electric field, and the controller I is connected to the pulse power supply On II, control the output voltage mode of the pulse power supply II. The electrode plates installed on the furnace body 2 are mainly composed of a set of plates with the same polarity and a set of plates with different polarities. Potential area space and electric field action area space, the positive end of pulse power supply II provides an external positive potential to a group of pla...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, especially in that:

[0044] In this example, see Figure 4 , plates with different polarities are composed of vertical negative electrode plates 3' and vertical positive electrode plates 7', vertical negative electrode plates 3' and vertical positive electrode plates 7' are arranged in parallel in a vertical arrangement, and installed insulated On the side wall of the furnace body 2, the vertical negative electrode plate 3' and the vertical positive electrode plate 7' are electrically connected to the other positive terminal and the other negative terminal of the pulse power supply II respectively, so that the vertical negative electrode plate 3' The region where the slag-gold system 4 is located between the positive electrode plate 7' and the vertical positive electrode plate 7' forms an electric field action area space, and the pulse voltage applied by the pulse power supply II makes the electric field in the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com