Method for reducing emission of PM 2.5 and SO2 at outlet of wet desulphurization system

A technology for SO2 and desulfurization slurry, which is applied in chemical instruments and methods, separation methods, and separation of dispersed particles to achieve the effects of promoting reaction, improving desulfurization efficiency, and promoting SO2 to enter desulfurization slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

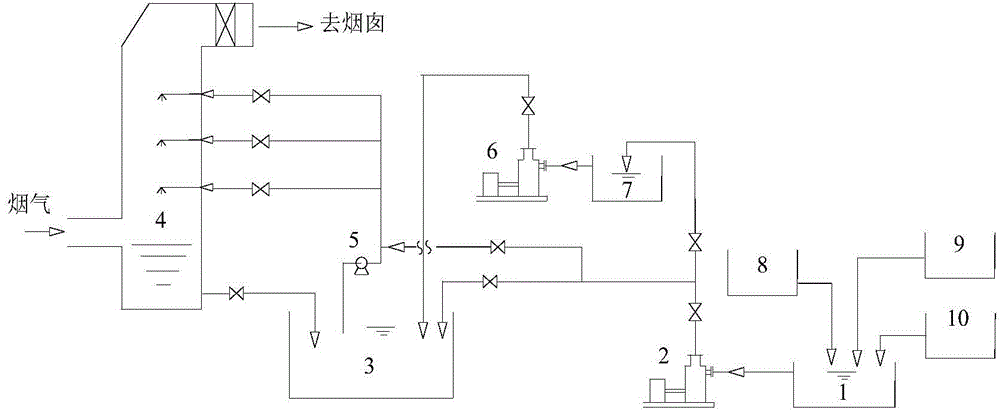

Image

Examples

Embodiment 1

[0029] The flue gas is produced by a fully automatic coal-fired boiler with a flue gas volume of 300Nm 3 / h, the desulfurization tower adopts a spray tower with a tower diameter of 200mm and a tower height of 4500mm, three-stage spraying, and a liquid-gas ratio of 18L / Nm 3 , the wet desulfurization technology is the limestone-gypsum method; the PM in the flue gas at the inlet of the desulfurization tower 2.5 The mass concentration is 17mg / m 3 , SO 2 The concentration is 1200mg / m 3 . The composition of the additive solution is as follows: 0.01% non-ionic polyacrylamide (molecular weight ≥ 5 million), 0.05% sulfamic acid, 0.05% sodium tripolyphosphate, 0.05% fatty acid monosulfate sodium compound salt. The dusty flue gas produced by the fully automatic coal-fired boiler enters the desulfurization tower after the coarse dust is removed by the electrostatic precipitator, and is in countercurrent contact with the limestone desulfurization slurry. Adopt electric low pressure im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com