Semi-solid preparation process for SiCp/ZL104 bearing bushes

A composite bearing bush and preparation technology, which is applied in the field of casting and pressure processing, can solve the problems of high cost, low welding strength, poor wear resistance of aluminum-based alloys, etc., and achieve the effect of low cost, high cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

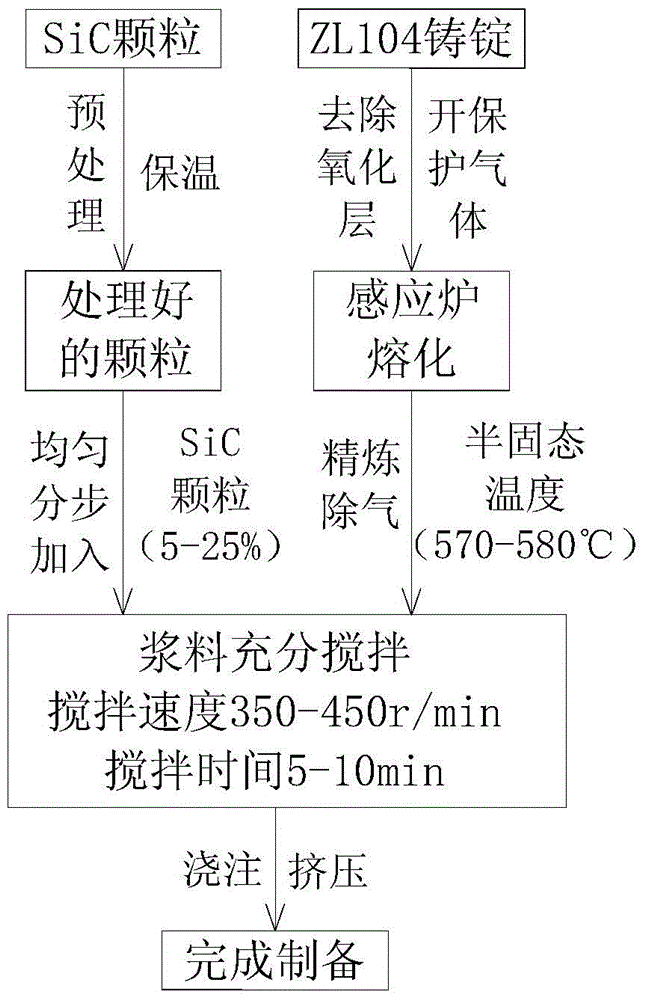

[0019] Referring to the accompanying drawings, a semi-solid preparation process of SiCp / ZL104 composite bearing comprises the following steps:

[0020] 1) Perform high-temperature pre-oxidation treatment on SiC particles. The process is to calcinate SiC particles with a size of 50-100um at a high temperature of 900-1100°C for 3 hours, and then perform heat preservation treatment in the range of 250-300°C;

[0021] 2) After grinding the ZL104 ingot to remove the oxide layer, put it into an intermediate frequency induction furnace and turn on the protective gas, heat the ZL104 ingot to above the liquidus line of 595°C to completely melt it, and after the thermocouple detects that the temperature is stable, gradually Adjust the power of the intermediate frequency induction furnace to stabilize the temperature in the furnace at 615-625°C and keep it warm for 10-15 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| solid fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap