Method for preparing high-flatness wide pure-molybdenum metal plate

A metal plate and flatness technology, which is applied in the field of preparing high-flatness and wide-width pure molybdenum metal plates, can solve the problems of low yield, low relative density and poor production flexibility of rolled plates, and can reduce the hot rolling billeting temperature. , the effect of increasing the relative density and simplifying the sintering process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

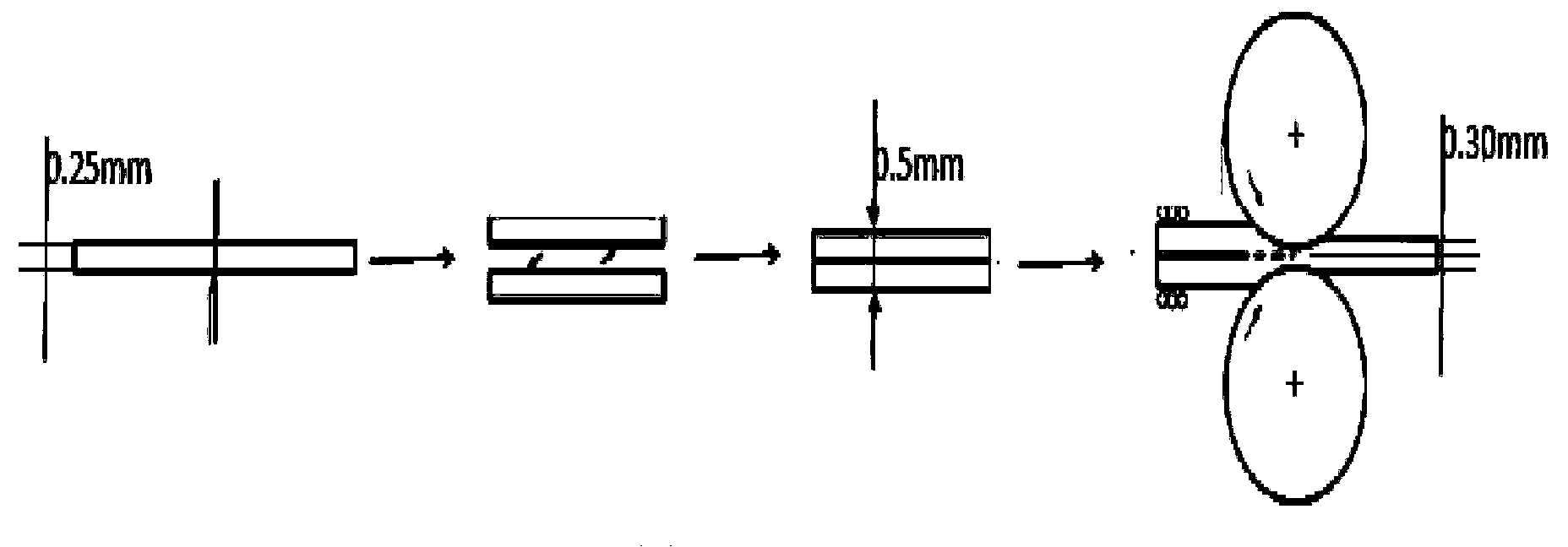

Image

Examples

Embodiment 1

[0057] The pure molybdenum metal powder is rolled into a billet, the rolling pressure is controlled at 40KN, and the rolling speed is controlled at 2.5cm / s, and the pure molybdenum powder is rolled into a thin plate green body with a thickness of 1.4mm.

[0058] The obtained pure molybdenum thin plate green body is placed in a high-temperature sintering furnace for sintering to obtain a pure molybdenum thin plate sintered body. The sintering temperature is 1300° C. and the sintering time is 1.5 hours.

[0059] The sintered slab is subjected to warm rolling, and the temperature of the slab is kept at 400°C, and several passes of warm rolling are performed until the total deformation of the sheet reaches 40%.

[0060] The warm-rolled pure molybdenum sheet is placed in a high-temperature furnace for heat treatment at a temperature of 1200°C for 1 hour.

[0061] Warm rolling is performed on the heat-treated pure molybdenum sheet, and this is repeated several times to obtain a pure...

Embodiment 2

[0065] The pure molybdenum metal powder is rolled into a billet, the rolling pressure is controlled at 60KN, and the rolling speed is controlled at 2.0cm / s, and the pure molybdenum powder is rolled into a thin plate green body with a thickness of 1.1mm.

[0066] The obtained pure molybdenum sheet green body is placed in a high-temperature furnace for sintering to obtain a pure molybdenum sheet sintered body. The sintering temperature is 1250° C. and the sintering time is 2 hours.

[0067] The sintered slab is subjected to warm rolling, and the temperature of the slab is kept at 400°C, and several passes of warm rolling are performed until the total deformation of the sheet reaches 40%.

[0068] Put the warm-rolled pure molybdenum sheet into a high-temperature furnace for heat treatment at a temperature of 1150°C for 1.5 hours.

[0069] The treated pure molybdenum sheet is then subjected to warm rolling, and this is repeated several times to obtain a pure molybdenum sheet with ...

Embodiment 3

[0073] The pure molybdenum metal powder is rolled into a blank, the rolling pressure is controlled at 80KN, and the rolling speed is controlled at 1.5cm / s, and the pure molybdenum powder is rolled into a thin plate green body with a thickness of 0.9mm.

[0074] The obtained pure molybdenum sheet green body is placed in a high-temperature furnace for sintering to obtain a pure molybdenum sheet sintered body. The sintering temperature is 1200° C. and the sintering time is 2 hours.

[0075] The sintered slab is subjected to warm rolling, and the temperature of the slab is kept at 350°C, and several passes of warm rolling are performed until the total deformation of the sheet reaches 40%.

[0076] The warm-rolled pure molybdenum sheet is placed in a high-temperature furnace for heat treatment at a temperature of 1100°C for 2 hours.

[0077] After reburning, the pure molybdenum sheet is subjected to warm rolling, and this is repeated many times to obtain a pure molybdenum sheet wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com