Coal powder pyrolysis and gasification method

A pulverized coal, pyrolysis technology, applied in the field of coal gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

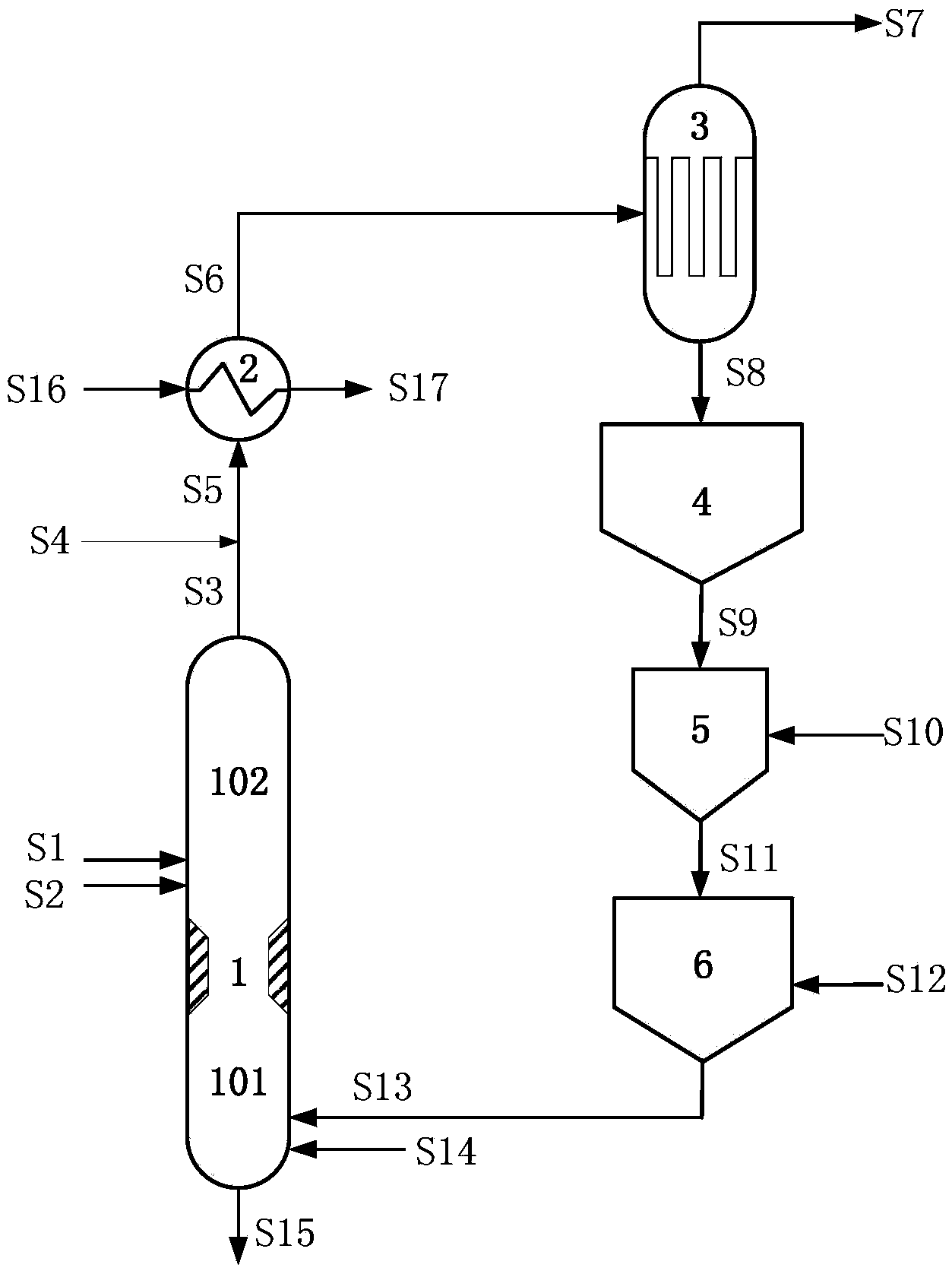

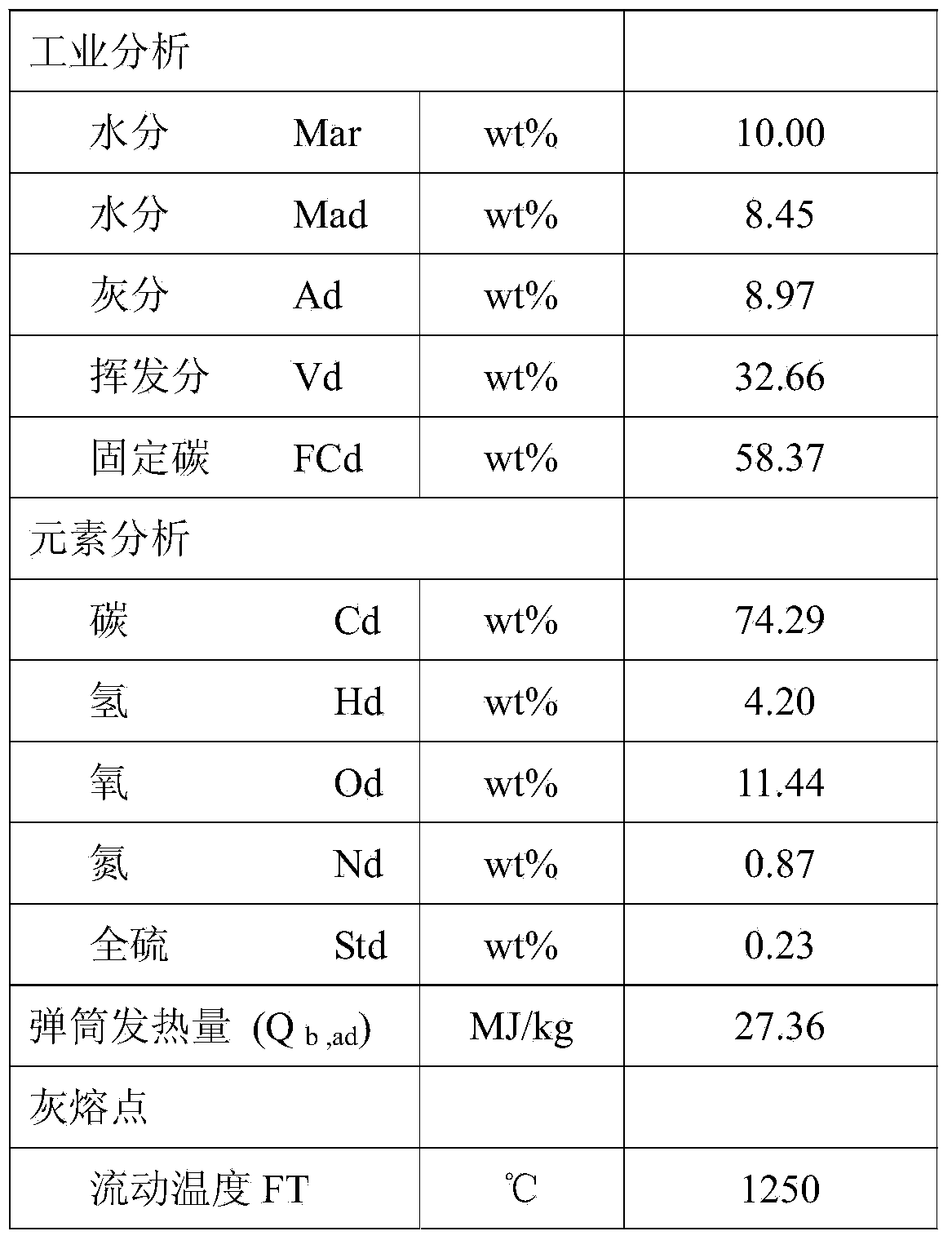

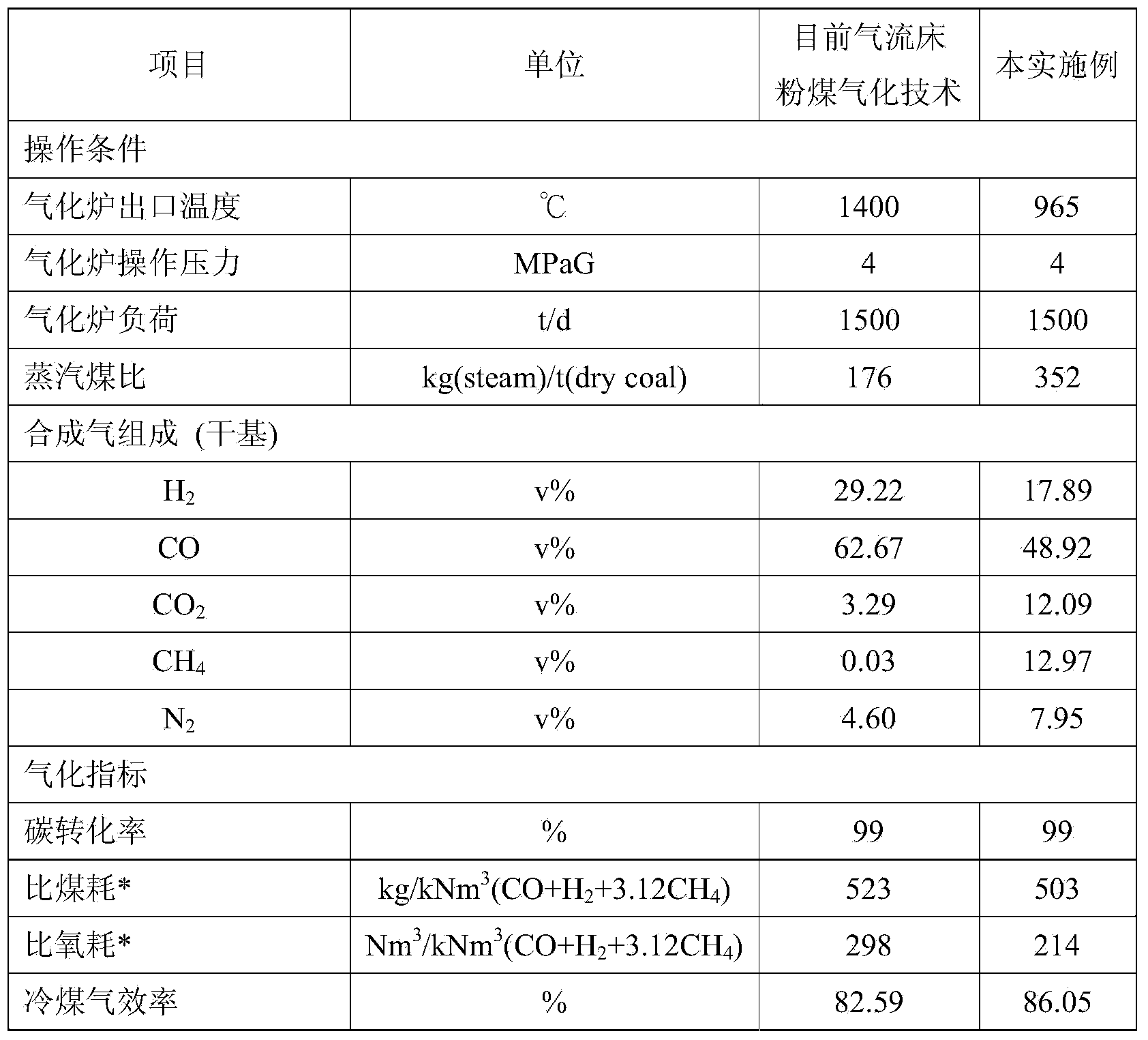

[0042] For the production of syngas by the gasification technology of entrained bed pulverized coal pyrolysis and semi-coke gasification, the sensible heat in the high-temperature gasification syngas of semi-coke is recovered by means of pulverized coal pyrolysis, and the syngas CH 4 The content is high, the cold gas efficiency of the system is high, and it can be widely used in the preparation of methane-rich synthesis gas or fuel gas with high calorific value. Table 1 shows the properties of raw coal. The pressure of the gasifier is 4.0MPa, and the processing capacity of a single gasifier is greater than 1000 tons (dry basis coal) per day.

[0043] Table 1 Properties of raw coal

[0044]

[0045] In this embodiment, the gasifier consists of two stages: an entrained bed pulverized coal pyrolysis furnace and an entrained bed semi-coke gasifier. All pulverized coal passes through N 2 Conveying into the entrained bed pulverized coal pyrolysis furnace, the synthetic gas cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com