Xylylene diisocyanate rectification apparatus and rectification method thereof

A xylylene diisocyanate and rectification technology, which is applied in the direction of isocyanic acid derivative purification/separation, fractionation, steam distillation, etc. Diisocyanate purity can not meet people's requirements and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

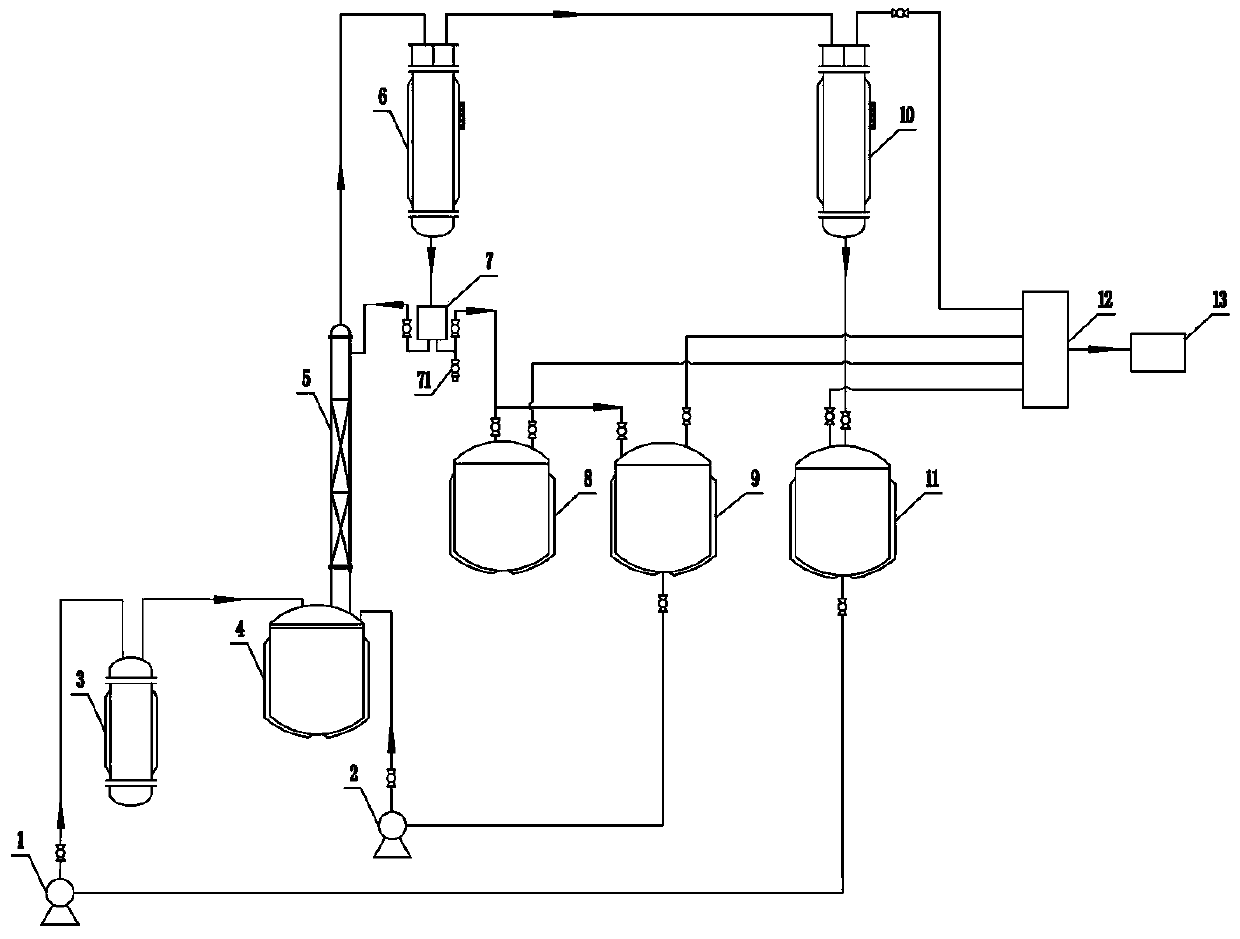

[0032] Such as figure 1 Shown, a kind of xylylene diisocyanate rectification device, it comprises organic solvent heater 3, crude product reboiler 4, rectifying column 5, primary condenser 6, finished product tank 8, crude solvent receiving tank 9 , high vacuum unit 12 and tail gas treatment system 13, each equipment is connected into a closed circuit according to a specific order.

[0033] The gas phase outlet of the organic solvent heater 3 is connected with the material inlet of the crude product reboiler 4, and the gas phase outlet of the crude product reboiler 4 is connected with the gas phase inlet of the rectifying tower 5, and the organic solvent is in the organic After being vaporized in the solvent heater 3, it enters the crude product reboiler 4 and mixes with the vaporized xylylene diisocyanate raw material, and then enters t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com