Method of preparing 2, 4, 5-trifluorobenzoic acid by microstructural reactor

A microstructure reactor, the technology of trifluorobenzoic acid, which is applied in the preparation of carboxylate, the preparation of carboxylate/lactone, organic chemistry, etc., can solve the problem of inability to realize continuous operation, difficult mass production, and many reaction steps, etc. problem, to achieve the effect of no amplification effect, continuous process, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

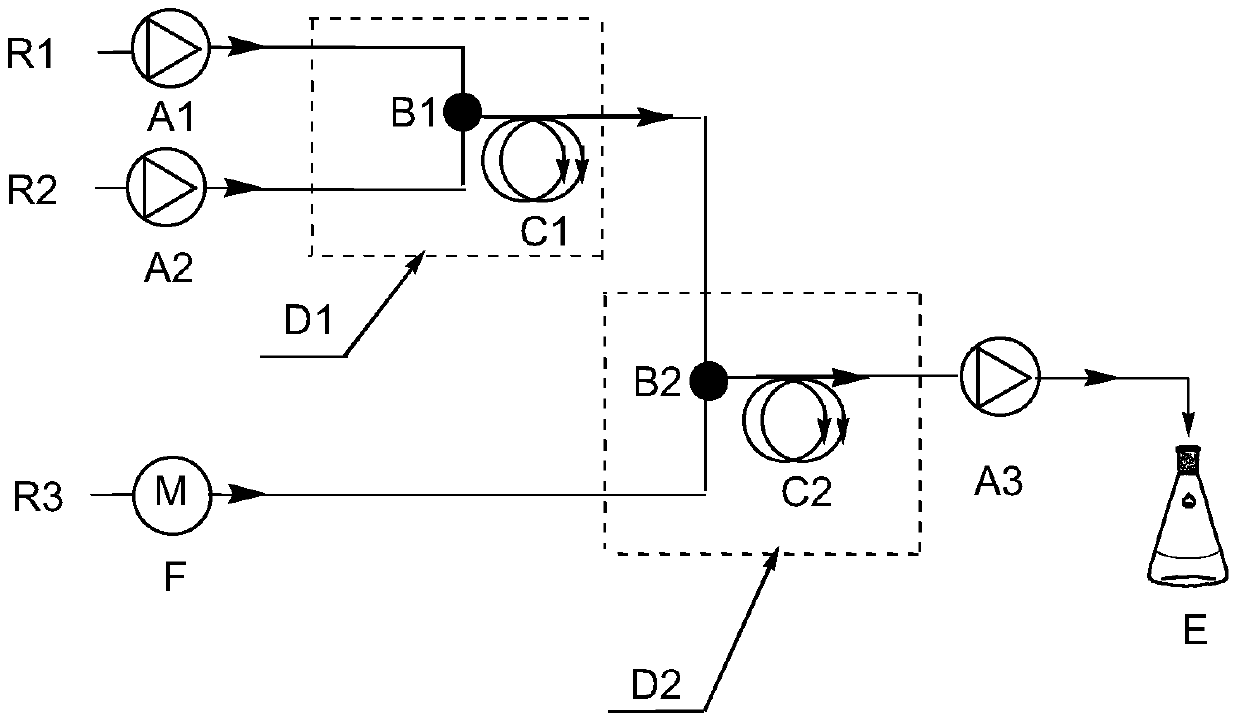

[0023] Ethylmagnesium bromide tetrahydrofuran solution (1M) and 2,4,5-trifluorobromobenzene tetrahydrofuran solution (1M) were injected into micro-mixer B1 (cross-toed micro Mixer, HPIMM, IMM, Germany, length × width × height = 25 × 21 × 37 μm) mixed, then enter the microchannel reactor C1 (inner diameter: 1mm) and carry out Grignard exchange at the temperature of the incubator D1 (10°C) And react for 2min, the product 2,4,5-trifluorophenylmagnesium bromide is metered into CO by F 2 The gas enters the micro-mixer B2 (V2, IMM, Germany, width × depth = 45 × 200 μm) according to the flow rate ratio of 1:10, and then enters the microchannel reactor C2 (inner diameter: 1mm), and continues in the incubator D2 (10°C) Carry out nucleophilic addition at high temperature and react for 0.5min, pump the product collection bottle E pre-filled with ammonium chloride aqueous solution and diethyl ether by plunger pump A3, add glacial acetic acid solution to the collection bottle E under stirr...

Embodiment 2

[0025] Ethylmagnesium bromide tetrahydrofuran solution (0.5M) and 2,4,5-trifluorobromobenzene tetrahydrofuran solution (0.5M) were injected into micro-mixer B1 (cross-toed Type micro-mixer, HPIMM, IMM, Germany, length × width × height = 25 × 21 × 37μm), enter the microchannel reactor C1 (inner diameter: 1mm) and continue to carry out the grid at the temperature of the incubator D1 (20°C). Exchange and react for 5min, the product 2,4,5-trifluorophenylmagnesium bromide and CO 2 The gas flow rate ratio is 1:20 and enters the falling film microstructure reactor B2 (length × width: 300 × 100μm) for mixing, then enters the microchannel reactor C2 (inner diameter: 2mm), and continues to carry out at the temperature of the incubator D2 (20°C) Nucleophilic addition and reaction for 5 minutes, pumped by plunger pump A3 into the product collection bottle E pre-installed with ammonium chloride aqueous solution and ether, adding sulfuric acid solution to the collection bottle E under stirr...

Embodiment 3

[0027] Ethylmagnesium bromide tetrahydrofuran solution (1.5M) and 2,4,5-trifluorobromobenzene tetrahydrofuran solution (1.5M) were injected into micro-mixer B1 (cross-toed Type micro-mixer, HPIMM, IMM, Germany, length × width × height = 25 × 21 × 37μm) and then enter the microchannel reactor C1 (inner diameter: 1mm) to continue at the temperature of the incubator D1 (40°C) Grignard exchange and reaction for 8 minutes, the product 2,4,5-trifluorophenylmagnesium bromide and CO 2The gas enters the falling film microstructure reactor B2 (length×width: 300×100μm) at a flow rate ratio of 1:25, and then enters the microchannel reactor C2 (inner diameter: 3mm), and continues to be heated at the temperature of the incubator D2 (30°C). Carry out nucleophilic addition and react for 10 minutes, pump into the product collection bottle E pre-installed with ammonium chloride aqueous solution and diethyl ether by plunger pump A3, add hydrochloric acid solution in the collection bottle E under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com