Material capable of realizing ultraviolet-light crosslinking and application thereof to 3D printing material

A 3D printing and crosslinking agent technology, which is applied in the field of ultraviolet 3D printing crosslinked polyester materials and its preparation, can solve the problems of slow crosslinking speed and unsuitability for the application of 3D printing materials, and achieve low production cost and easy Effect of industrial production and improvement of molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

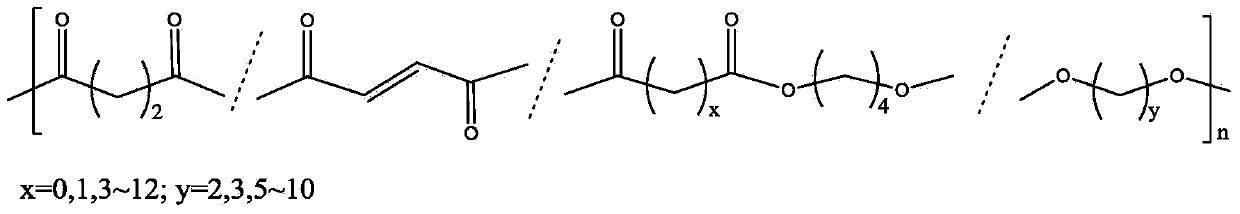

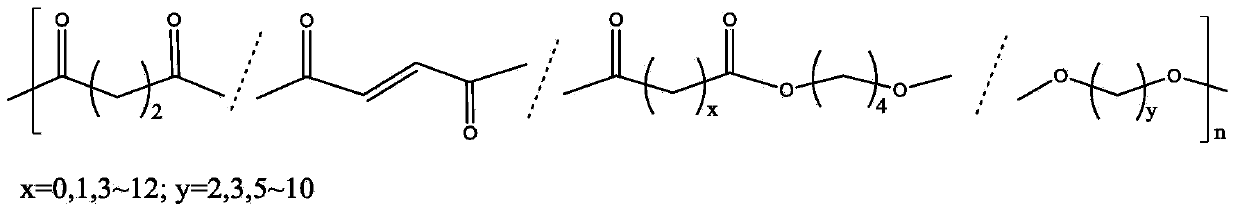

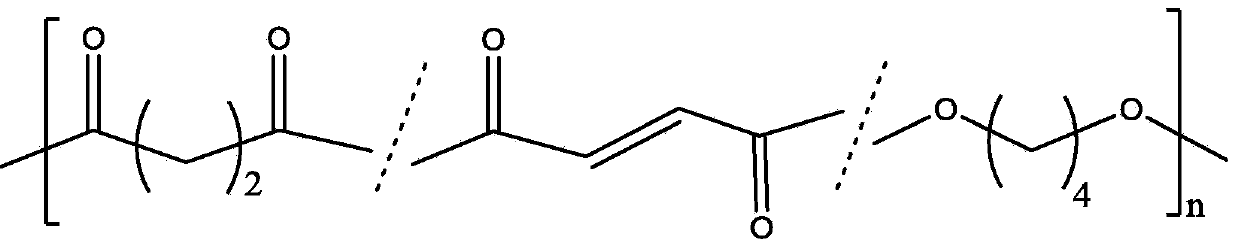

[0047] 1) Preparation of aliphatic polyester prepolymers containing double bonds

[0048] At room temperature, add 1,4-butanedioic acid, fumaric acid, 1,4-butanediol, zinc chloride and hydroquinone at a molar ratio of 1:1:2:0.01:0.005, totaling 2500g, and add it to high purity nitrogen Replaced in a 5L reactor. At the same time, the reactor is equipped with a high-purity nitrogen inlet, a mechanical stirrer, and a condenser. The above reaction system is controlled at 150°C, and the reaction is stirred with nitrogen until the water output reaches 95% of the theoretical water output, then the polycondensation catalyst (butyl titanate) 0.05g / 100g polymer is added, the pressure is slowly reduced to 50Pa, and then polycondensation 9 hours. The PBS copolyester is obtained, and its structural formula is shown in formula 2. According to the integrated area of the hydrogen NMR spectrum, the number average molecular weight can be calculated to be 26,000.

[0049]

[0050] Formula 2

[0...

Embodiment 2

[0055] 1) Preparation of aliphatic polyester prepolymers containing double bonds

[0056] At room temperature, first add 2500g of succinic acid, maleic anhydride, 1,4-butanediol, zinc chloride and hydroquinone at a molar ratio of 0.96:0.04:2:0.01:0.003 to 5L replaced with high purity nitrogen In the reactor. At the same time, the reactor is equipped with a high-purity nitrogen inlet, a mechanical stirrer, and a condenser. The above reaction system is controlled at 250°C, and the reaction is stirred with nitrogen until the water output reaches 95% of the theoretical water output, then a polycondensation catalyst (stannous octoate) 0.5g / 100g polymer is added, the pressure is slowly reduced to 5Pa, and then polycondensation 3 hour. The PBS copolyester is obtained. According to the integrated area of the proton NMR spectrum, the number average molecular weight can be calculated to be 1000.

[0057] 2) Combine 98.15 parts of the aliphatic polyester prepolymer obtained in step 1) w...

Embodiment 3

[0061] 1) Preparation of aliphatic polyester prepolymers containing double bonds

[0062] At room temperature, first add 2500g of succinic acid, fumaric acid, maleic anhydride, 1,4-butanediol, zinc chloride and hydroquinone at a molar ratio of 0.8:0.1:0.1:2:0.1:0.05 to the high In a 5L reactor replaced by pure nitrogen. At the same time, the reactor is equipped with a high-purity nitrogen inlet, a mechanical stirrer, and a condenser. The above reaction system was controlled at 180°C, and the reaction was stirred with nitrogen until the water output reached 95% of the theoretical water output. Then, the polycondensation catalyst (isopropyl titanate) 0.5g / 100g polymer was added, and the pressure was slowly reduced to 5Pa. Polycondensation for 3 hours. The PBS copolyester is obtained. According to the integrated area of the proton NMR spectrum, the number average molecular weight can be calculated to be 13,000.

[0063] 2) Combine 96.5 parts of the aliphatic polyester prepolymer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com