Flame-retardant composite material component with high thermal conductivity and high heat radiation property and preparation method of flame-retardant composite material component

A composite material, high heat dissipation technology, applied in flame retardant, high thermal conductivity, high heat dissipation nylon material and its preparation, application field of modified polymer material, can solve the problem of low thermal conductivity and heat dissipation performance, accelerated aging degree of the system, and anti-oxidation performance. Defects and other problems, to achieve the effect of reducing the amount of absorbed light, improving aging resistance, and small thermal expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

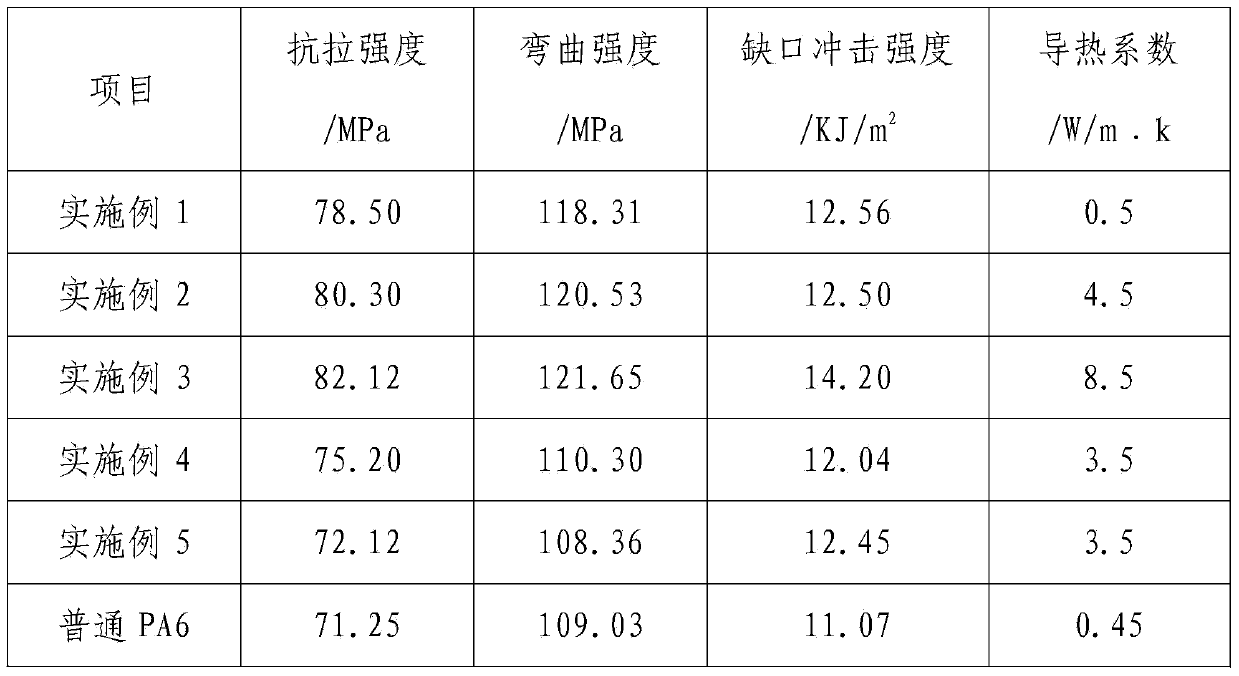

Embodiment 1

[0025] A component of a flame-retardant, high-thermal-conduction, high-heat-dissipation composite material, which contains materials and corresponding molar contents as follows: polyamide 20%, magnesium hydroxide 30%, silicon carbide 1%, polytetrafluoroethylene 1%, compatible Agent 20%, antioxidant 20%, processing aid 8%.

Embodiment 2

[0027] A component of a flame-retardant, high-thermal-conductivity, high-heat-dissipation composite material, which contains materials and corresponding molar contents as follows: 20% polyamide, 30% magnesium hydroxide, 1% silicon carbide, 10% polytetrafluoroethylene, compatible Agent 20%, antioxidant 10%, processing aid 9%.

Embodiment 3

[0029] A component of a flame-retardant, high-thermal-conductivity, high-heat-dissipation composite material, which contains materials and corresponding molar contents as follows: 20% polyamide, 30% magnesium hydroxide, 20% silicon carbide, 10% polytetrafluoroethylene, compatible Agent 10%, antioxidant 1%, processing aid 9%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com