Barium sulfate and preparation method thereof

A barium sulfate and barium source technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve the problems of restricting the use of a large amount of barium sulfate, unfavorable addition of barium sulfate, and reducing the density of barium sulfate, so as to achieve mechanical strength and processability Excellent, easy to industrialized production, good mechanical strength and processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) The 5.0mol / L barium chloride solution of 85 parts by weight is added in the emulsification tank, the pH value of the barium chloride solution is adjusted to 7 with a pH regulator, then add 3 parts by weight of sodium stearate, 10 parts by weight 100% paraffin, emulsified by ultrasonic wave for 100min, the solution is emulsified to form uniform and stable oil-in-water structure droplets, the size of the oil core of the emulsion droplets can be controlled and adjusted according to the length of emulsification time and the amount of emulsifier;

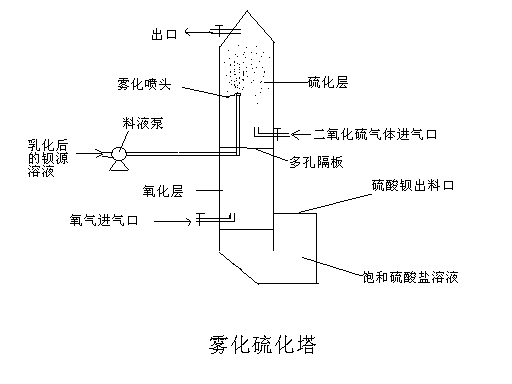

[0037] 2) Pressurize the emulsion obtained in step 1) with a material liquid pump, and then atomize it through a nozzle to form a single small liquid droplet with an oil-in-water structure, and vulcanize the atomized liquid droplet by sulfur dioxide gas and oxygen respectively. Oxidation, that is, sulfur dioxide gas first dissolves in the liquid beads to form sulfite, sulfite and barium ions form barium sulfite, then barium sulfit...

Embodiment 2

[0040] 1) The 3.0mol / L barium chloride solution of 90 parts by weight is added in the emulsification tank, the pH value of the barium chloride solution is adjusted to 8 with a pH regulator, then add 4 parts by weight of sodium stearate, 12 parts by weight Use ultrasonic waves to carry out emulsification treatment for 80 minutes to make the solution emulsify to form uniform and stable oil-in-water structure droplets. The size of the oil core of the emulsion droplets can be controlled and adjusted according to the length of emulsification time and the amount of emulsifier;

[0041] 2) Pressurize the emulsion obtained in step 1) with a material liquid pump, and then atomize it through a nozzle to form a single small liquid droplet with an oil-in-water structure, and vulcanize the atomized liquid droplet by sulfur dioxide gas and oxygen respectively. Oxidation, that is, sulfur dioxide gas first dissolves in the liquid beads to form sulfite, sulfite and barium ions form barium sulfi...

Embodiment 3

[0045] 1) The 2.0mol / L barium chloride solution of 90 parts by weight is added in the emulsification tank, the pH value of the barium chloride solution is adjusted to 9 with a pH regulator, and then the dodecylbenzenesulfonic acid of 5 parts by weight is added Sodium and 15 parts by weight of oxidized polyethylene wax are emulsified by ultrasonic waves for 80 minutes to emulsify the solution to form uniform and stable oil-in-water droplets. to control and adjust;

[0046] 2) Pressurize the emulsion obtained in step 1) with a material liquid pump, and then atomize it through a nozzle to form a single small liquid droplet with an oil-in-water structure, and vulcanize the atomized liquid droplet by sulfur dioxide gas and oxygen respectively. Oxidation, that is, sulfur dioxide gas first dissolves in the liquid beads to form sulfite, sulfite and barium ions form barium sulfite, then barium sulfite is quickly oxidized by oxygen to barium sulfate, the barium source solution on the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com