Functional granular major-element water soluble fertilizer and preparation method thereof

A large amount of elements, granular technology, applied in the direction of fertilization device, fertilizer mixture, application, etc., can solve the problems of water retention and drought resistance, soil repair and improvement, inability to mix nutrients organically, loose structure, etc., to improve crop yield and quality , Improve fertilizer utilization rate, improve water retention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 350 parts of urea, 220 parts of potassium nitrate, 250 parts of potassium dihydrogen phosphate, 115 parts of monoammonium phosphate, 30 parts of potassium sulfate, 11.6 parts of boric acid, 7.7 parts of EDTA chelated iron, 6.6 parts of EDTA chelated zinc, 3.9 parts of EDTA chelated manganese parts, 0.2 parts of ammonium heptamolybdate, and 5 parts of polyglutamic acid (PGA).

[0046] step 1 : Melt 350 parts of urea at high temperature (130°C-140°C), enter the buffer tank, pressurize it through the delivery pump, and send it to the mixing tank at the top of the tower after metering.

[0047] Step 2: 11.6 parts of boric acid, 6.6 parts of EDTA chelated zinc, 7.7 parts of EDTA chelated iron, 3.9 parts of EDTA chelated manganese, 5 parts of polyglutamic acid, 0.2 parts of ammonium heptamolybdate, and 30 parts of potassium sulfate are premixed in a certain proportion , and then measure the mixed material with 250 parts of potassium dihydrogen phosphate, 220 parts of pota...

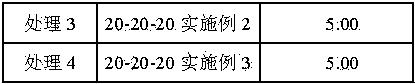

Embodiment 2

[0051] 347 parts of urea, 220 parts of potassium nitrate, 250 parts of potassium dihydrogen phosphate, 115 parts of monoammonium phosphate, 30 parts of potassium sulfate, 11.6 parts of boric acid, 7.7 parts of EDTA chelated iron, 6.6 parts of EDTA chelated zinc, 3.9 parts of EDTA chelated manganese parts, 0.2 parts of ammonium heptamolybdate, and 8 parts of polyglutamic acid (PGA).

[0052] The specific implementation steps are the same as the implementation example 1.

[0053] The obtained product specification is 20-20-20, containing 0.2% boron, 0.1% chelated iron, 0.1% chelated zinc, 0.05% chelated manganese, 0.01% molybdenum, and 0.8% polyglutamic acid (PGA)

Embodiment 3

[0055] 345 parts of urea, 220 parts of potassium nitrate, 250 parts of potassium dihydrogen phosphate, 115 parts of monoammonium phosphate, 30 parts of potassium sulfate, 11.6 parts of boric acid, 7.7 parts of EDTA chelated iron, 6.6 parts of EDTA chelated zinc, 3.9 parts of EDTA chelated manganese parts, 0.2 parts of ammonium heptamolybdate, and 10 parts of polyglutamic acid (PGA).

[0056] The specific implementation steps are the same as the implementation example 1.

[0057] The obtained product specification is 20-20-20, containing 0.2% boron, 0.1% chelated iron, 0.1% chelated zinc, 0.05% chelated manganese, 0.01% molybdenum, and 1.0% polyglutamic acid (PGA)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com