A kind of magnetization roasting method of high iron waste slag or minerals

A magnetization roasting and waste slag technology, applied in the direction of improving the process efficiency, can solve the problems of difficult to adapt to the complex composition of non-ferrous smelting high-speed iron materials, difficult to control the reduction intensity, increase the decoking process and other problems, achieve simple daily operation and maintenance, and good magnetization effect. , the effect of avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

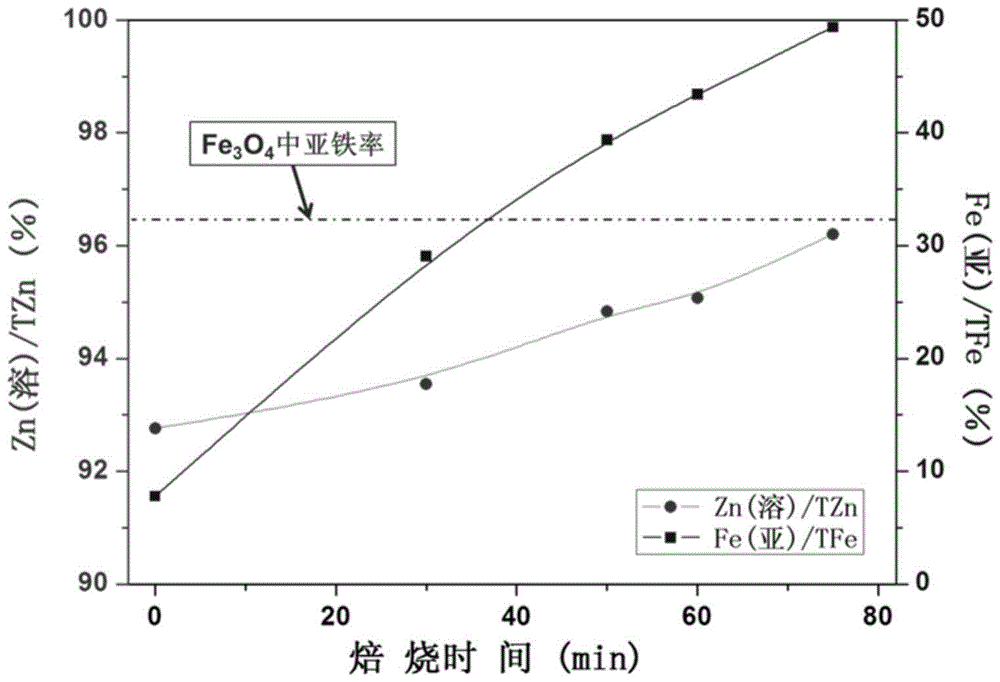

[0023] Using producer gas as fuel, magnetize and roast a certain iron-zinc calcine (containing 58.0% zinc, 7.4% iron, and its main phases are zinc oxide and zinc ferrite), so that the zinc ferrite is magnetized and decomposed into zinc oxide and ferroferric oxide. The gas composition is determined by the German MRU flue gas analyzer. The composition is shown in Table 1. The gas is mixed with a certain amount of air and ignited. After the furnace temperature rises to about 600 ° C, the gas flow rate is adjusted to 5~ 6Nm 3 / min, adjust the air intake volume to about 5Nm 3 / min, the temperature in the furnace is 700-750°C at this time, the composition concentration of the combustion tail gas is shown in Table 2, and the feed rate is 200kg / h, and the changes of the soluble zinc rate and ferrous rate of the material under different residence times are shown in the appendix figure 1 shown.

[0024] Table 1 Concentration of main components of producer gas ("—" means not detected b...

Embodiment 2

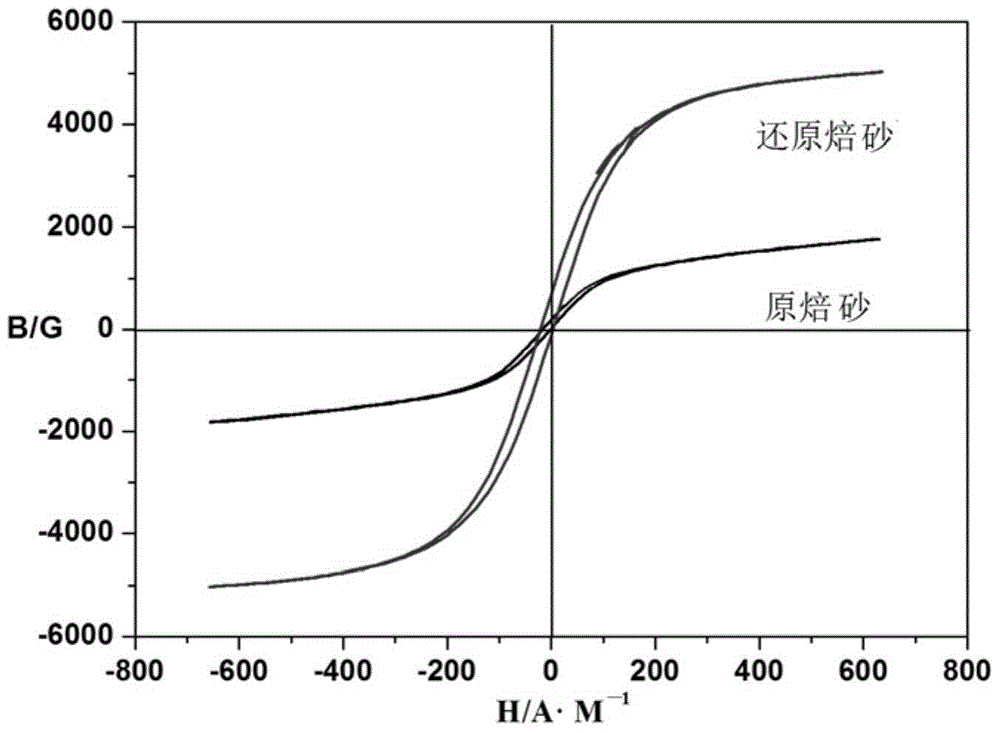

[0029] Natural gas is used as fuel, and the above-mentioned raw materials are also magnetized and roasted. The concentration of methane and other alkanes in natural gas is more than 95%, and the rest is a small amount of hydrogen sulfide. Mix the natural gas with a certain amount of air and ignite it. Adjust the temperature after the furnace temperature rises to about 700°C. The flow rate of natural gas is 1~1.2Nm 3 / min, adjust the air flow to about 4~5Nm 3 / min, the temperature in the furnace is 700~750℃ at this time, the composition concentration of the combustion tail gas is shown in Table 3, the hysteresis loops of the roasted products and raw materials are compared in the attached figure 2 shown.

[0030] Table 3 Concentration of main components of combustion exhaust gas

[0031] Element

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com