A kind of preparation method of heat-insulating and sterilizing car roof fabric and airgel felt

An airgel blanket and car roof technology, applied in the field of auto parts, can solve problems such as unfavorable health of passengers, moisture accumulation in the car, and obvious temperature difference, etc., achieve good heat insulation effect, strengthen mechanical strength, The effect of accelerated prototyping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

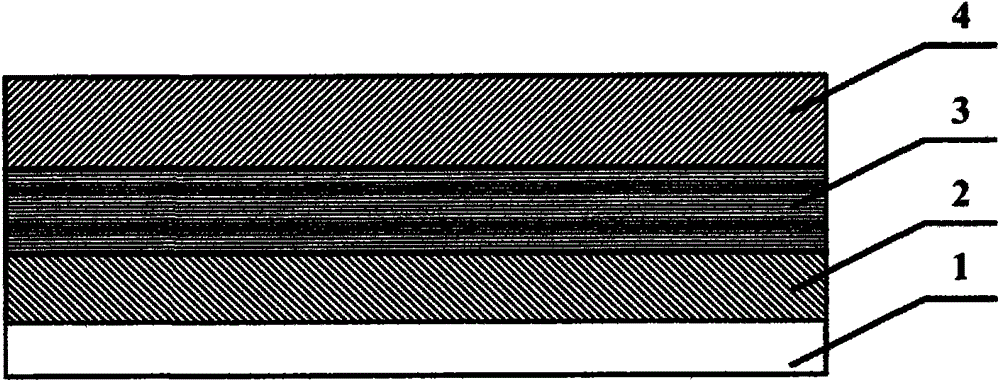

Image

Examples

preparation example Construction

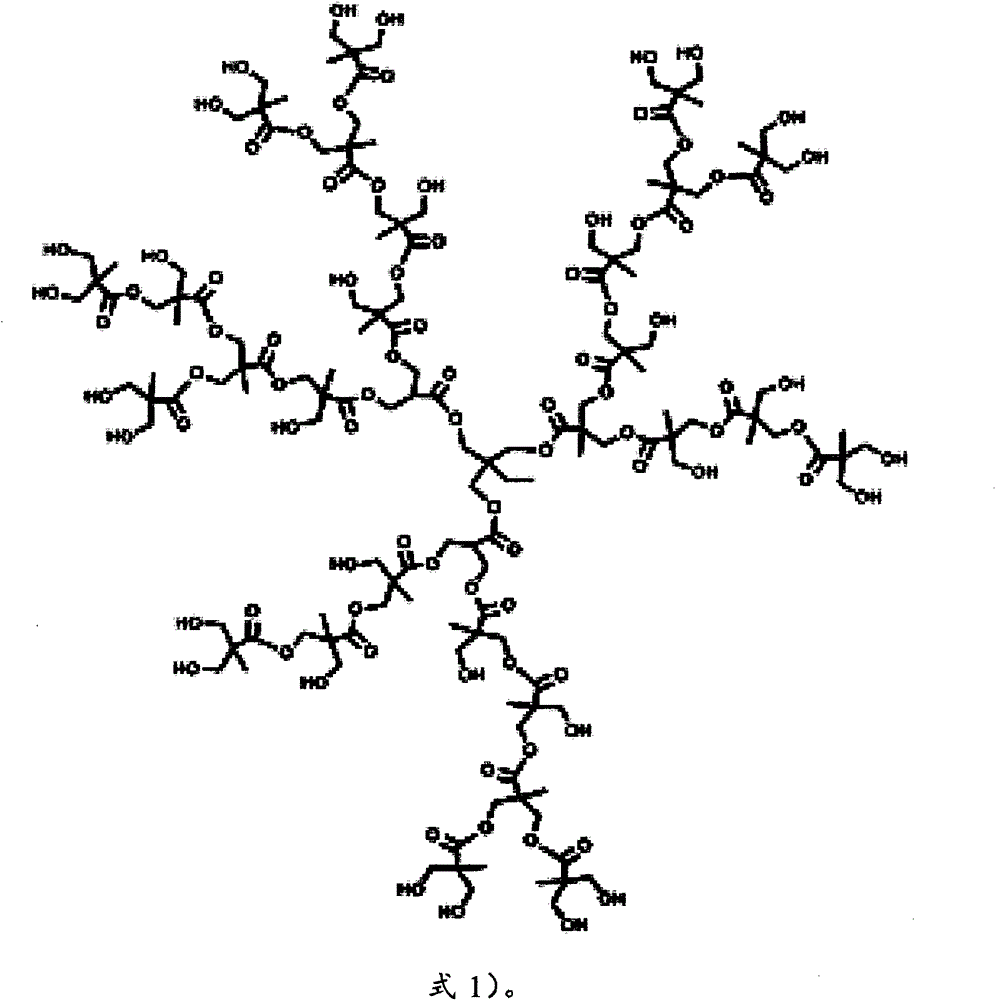

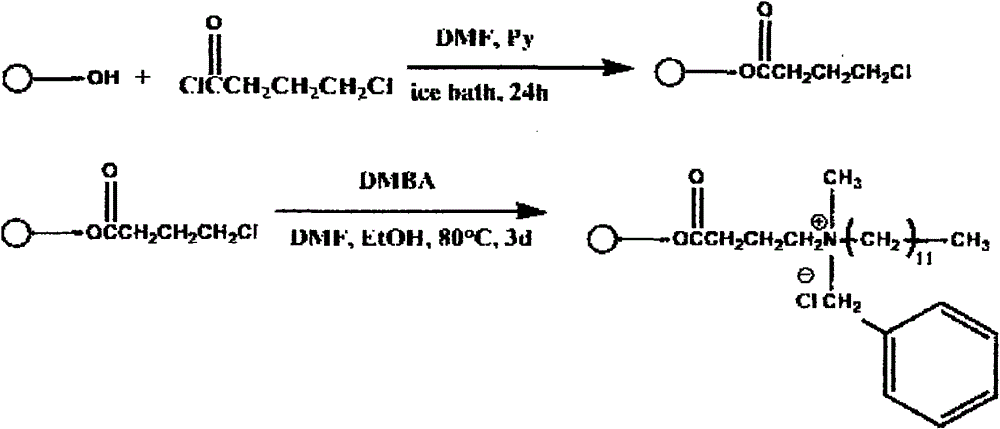

[0030] The preparation process of the hyperbranched polymer used in the present invention is as follows:

[0031]

[0032] in, It is hyperbranched polyester BoltornH30 (hereinafter referred to as H30), purchased from Sweden Perstorp company, its structural formula is shown in formula 1), DMF is N, N-dimethylformamide, Py is pyridine, and DMBA is dodecylmethylformamide benzylamine.

[0033]

[0034] Specifically, the hyperbranched polymer is preferably prepared according to the following method: the hyperbranched polyester BoltornH30 (H30) produced by Sweden's Perstorp company is dissolved in N, N-dimethylformamide (DMF), and pyridine (Py) is added as a binding agent. Acid agent, then stirred in an ice-water bath, slowly added 4-chlorobutyryl chloride dropwise, warmed up to room temperature after the dropwise addition, stirred and reacted for 24 hours, then dropped into water to precipitate, centrifuged to separate a brown sticky solid, the brown sticky solid Dissolve ...

Embodiment 1

[0052] Dissolve 10g of hyperbranched polyester H30 in 50mL of DMF, add 14.1mL of pyridine, stir in an ice-water bath, slowly drop in 20mL of 4-chlorobutyryl chloride, warm up to room temperature after the addition, stir for 24 hours, and pour the reaction mixture into Put it into 500mL deionized water, precipitate a brown viscous solid, centrifuge at 10000r / min, separate the solid and dissolve it in 50mL acetone, drop it into 500mL for precipitation, centrifuge at 10000r / min, repeat three times, and dry the obtained solid to obtain terminal chloride Modified hyperbranched polyester C1-H3018.5g, yield 81.4%.

[0053] Dissolve 10g of terminal chlorine-modified hyperbranched polyester C1-H30 in 50mL of DMF, stir and add 40mL of ethanol and 60mL of dodecylmethylbenzylamine, heat up to 80°C for three days, and cool the reaction system to room temperature , Pour the reaction mixture into 500mL acetone, precipitate a light brown solid, centrifuge at 10000r / min, redissolve the separat...

Embodiment 2

[0056] (1) Provide network-like cellulose nanofiber skeleton

[0057] Inoculate the pre-cultivated seed culture solution of Acetobacter xylinum into 10L Acetobacter xylinum fermentation medium with an inoculation amount of 13%, shake it fully, and culture it at a constant temperature of 30°C for 20 days to obtain a cellulose hydrogel . The Acetobacter xylinum fermentation broth contains 4% glucose, 0.8% protein, 0.5% yeast powder, 0.35% disodium hydrogen phosphate pentahydrate, 0.115% citric acid-hydrate, pH is 6.2, and is sterilized at high temperature for 20 minutes. The cellulose hydrogel fermented by microorganisms was placed in 5% NaOH aqueous solution at 90°C for 12 hours, then placed in deionized water at 80°C for 12 hours, during which the deionized water was replaced 4 times, and then the volume ratio was 2: 3. The mixed solution of tert-butanol and deionized water was subjected to solvent replacement at 60°C for 12 hours, and the mixed solution was replaced twice du...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com