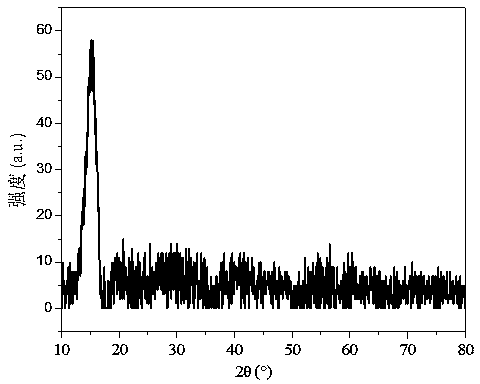

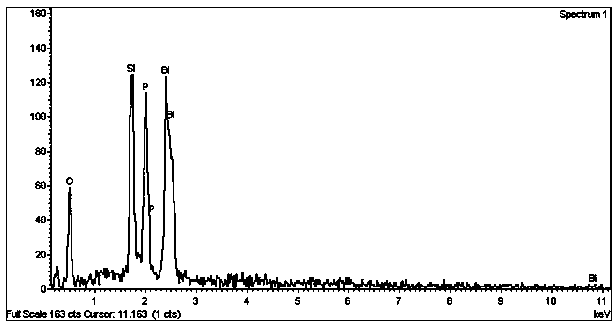

Preparation method of phosphorus doped bismuth phosphate photocatalyst

A photocatalyst and bismuth phosphate technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of insufficient research and rare phosphorus-doped bismuth phosphate, and achieve novel methods, High photocatalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1. Preparation of precursor: Weigh 6 g of red phosphorus and add it to 80 mL of deionized water, and stir the suspension for 12 hours under the condition of sufficient stirring.

[0028] The mixed phase obtained above was put into a 100 mL polytetrafluoroethylene autoclave, the hydrothermal reaction time was 12 hours, and the hydrothermal reaction temperature was 180 ° C. The obtained dark red solid was washed several times with deionized water, and placed in After vacuum drying at 80 °C for 12 h, the red phosphorus precursor with surface oxide removed was obtained.

[0029] 2. Preparation of phosphorus-doped bismuth phosphate photocatalyst: Weigh 0.725g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) Dissolve in 15 mL of nitric acid aqueous solution with a concentration of 4 mol / L, stir and dissolve thoroughly to obtain solution A.

[0030] Weighed 0.6 g of the red phosphorus precursor obtained in step 1, and added it to solution A under magnetic stirring. After ultrasonic tr...

Embodiment 2

[0037] 1. Preparation of the precursor: Weigh 8 g of red phosphorus and add it to 80 mL of deionized water, and stir the suspension for 12 hours under the condition of sufficient stirring.

[0038] Put the mixed phase obtained above into a 100 mL polytetrafluoroethylene autoclave, the hydrothermal reaction time is 12 hours, and the hydrothermal reaction temperature is 180 ° C. The obtained dark red substance is washed several times with deionized water, and vacuum-dried After 12 h at a temperature of 80 °C, the red phosphorus precursor with surface oxide removed was obtained.

[0039] 2. Preparation of phosphorus-doped bismuth phosphate photocatalyst: Weigh 2.9 g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) Dissolve in 80 mL of nitric acid aqueous solution (concentration: 3 mol / L), fully stir and dissolve to obtain solution A.

[0040] Weigh 2 g of the red phosphorus precursor obtained in step 1 and add it to solution A under magnetic stirring. After ultrasonic treatment for 30 mi...

Embodiment 3

[0043] 1. Preparation of the precursor: Weigh 4 g of red phosphorus and add it to 80 mL of deionized water, and stir the suspension for 12 hours with sufficient stirring.

[0044] Put the mixed phase obtained above into a 100 mL polytetrafluoroethylene autoclave, the hydrothermal reaction time is 12 hours, and the hydrothermal reaction temperature is 180 ° C. The obtained dark red substance is washed several times with deionized water, and vacuum-dried After 12 h at a temperature of 80 °C, the red phosphorus precursor with surface oxide removed was obtained.

[0045] 2. Preparation of phosphorus-doped bismuth phosphate photocatalyst: Weigh 0.725g bismuth nitrate (Bi(NO 3 ) 3 ·5H 2 O) Dissolve in 15 mL of nitric acid aqueous solution with a concentration of 4 mol / L, stir and dissolve thoroughly to obtain solution A.

[0046] Weigh 0.5 g of the red phosphorus precursor obtained in step 1, add it into solution A under magnetic stirring, and after ultrasonic treatment for 20 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com