Preparation method for amphiphilic nanometer particle and application of amphiphilic nanometer particle to prepare Pickering emulsion

A nanoparticle, amphiphilic technology, applied in nanotechnology, hybrid methods, nanotechnology, etc., can solve the problems of limited promotion and practical application, complicated operation, harsh reaction conditions, etc., and achieve great application prospects and industrialization capabilities, preparation. Simple process and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

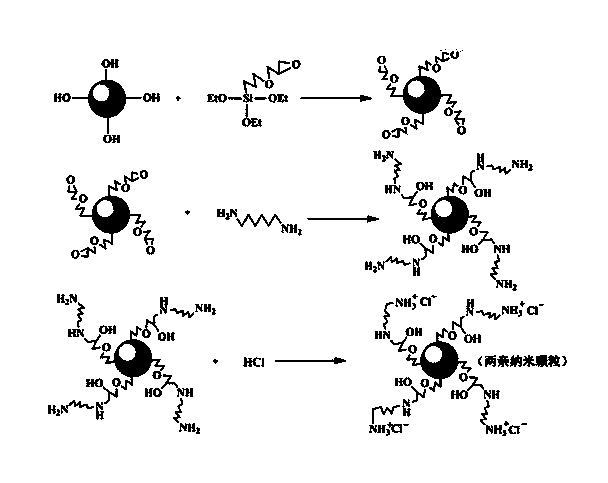

[0035] A kind of amphiphilic nanoparticle, it is prepared according to the following method:

[0036] (1) Preparation of epoxy-modified nanoparticles:

[0037] First disperse 0.5-2.0g of nanoparticles in 30-60g of ethanol, then drop 1-4g of glycidyl etheroxypropyl triethoxysilane into it drop by drop, stir vigorously, and react at 50-70°C for 18-24h ; Then carry out centrifugal separation, after the nanoparticles are separated, wash with deionized water for 1-3 times, then wash with ethanol for 1-3 times, and finally vacuum dry at 80-100°C for 10-16h to obtain epoxy-modified Sexual nanoparticles;

[0038] (2) Preparation of amino-modified nanoparticles:

[0039] First, disperse 0.5-2.0g of epoxy-modified particles in 30-60g of ethanol, add 1-2g of hexamethylenediamine, stir well, and react at 50-70°C for 4-10h; then perform centrifugation to separate the nanoparticles After coming out, wash with deionized water for 1-3 times, then wash with ethanol for 1-3 times, and finall...

Embodiment 1

[0058] Embodiment 1: a kind of amphiphilic nanoparticle, it is prepared according to the following method:

[0059] (1) Preparation of epoxy-modified nanoparticles:

[0060] Disperse 1.5g of nano-silica particles in 40g of ethanol, then drop 2g of glycidyl etheroxypropyltriethoxysilane (GPTEOS) dropwise into it, stir vigorously, and react at 50°C for 24h; then carry out After centrifugal separation, the nano-silica particles are separated, washed once with deionized water, washed twice with ethanol, and then vacuum-dried at 100°C for 10 hours to obtain epoxy-modified nano-silica particles;

[0061] (2) Preparation of amino-modified nanoparticles:

[0062] Weigh 1.5g of epoxy-modified nano-silica particles and disperse them in 40g of ethanol, add 1g of hexamethylenediamine, stir well, and react at 50°C for 6h; then perform centrifugation to separate the nano-silica particles , washed once with deionized water, washed twice with ethanol, and then vacuum-dried at 100°C for 10 h...

Embodiment 2

[0074] Embodiment 2: a kind of amphiphilic nanoparticle, it is prepared according to the following method:

[0075] (1) Preparation of epoxy-modified nanoparticles:

[0076] Disperse 1.0g of nano-titanium dioxide particles in 50g of ethanol, then drop 1.5g of glycidyl etheroxypropyltriethoxysilane (GPTEOS) dropwise into it, stir vigorously, and react at 50°C for 20h; then centrifuge Separation, after the nano-titanium dioxide particles are separated, they are washed once with deionized water and twice with ethanol, and then vacuum-dried at 100° C. for 10 hours to obtain epoxy-modified nano-titanium dioxide particles.

[0077] (2) Preparation of amino-modified nanoparticles:

[0078] Weigh 1.0 g of epoxy-modified nano-titanium dioxide particles and disperse them in 50 g of ethanol, add 1.5 g of hexamethylenediamine, stir well, and react at 50°C for 6 h; Wash once with deionized water, wash twice with ethanol, and then vacuum-dry at 100° C. for 12 hours to obtain amino-modifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com