Straw corrosion promoting microbial inoculant-coated biological organic fertilizer and preparation method thereof

A bio-organic fertilizer, a technology of organic fertilizer, applied in fertilizer mixture, fertilization device, application and other directions, can solve problems such as increasing the difficulty of straw decomposition, and achieve the effects of alleviating atmospheric environmental problems, increasing yield, and simple and easy process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

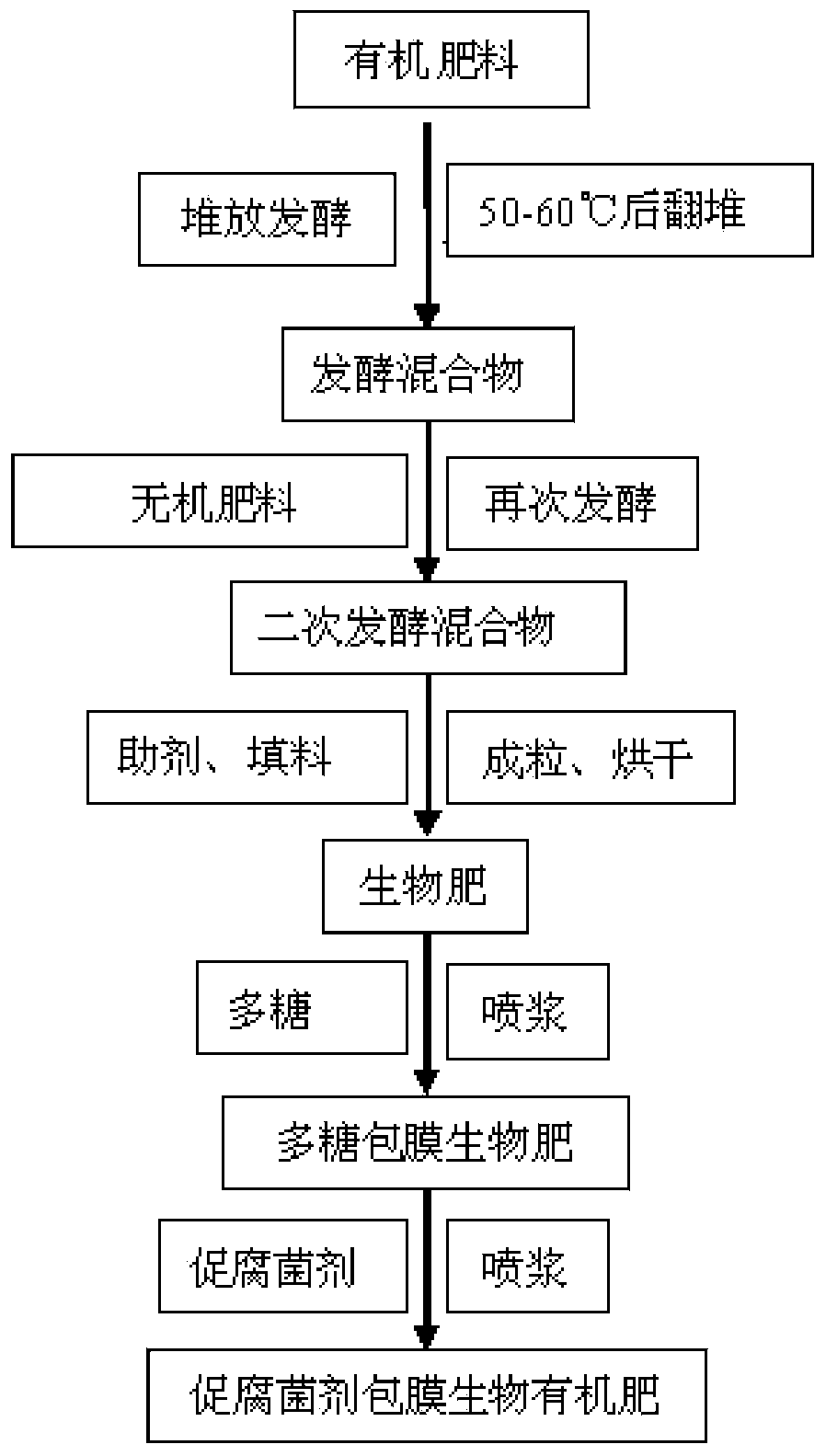

Method used

Image

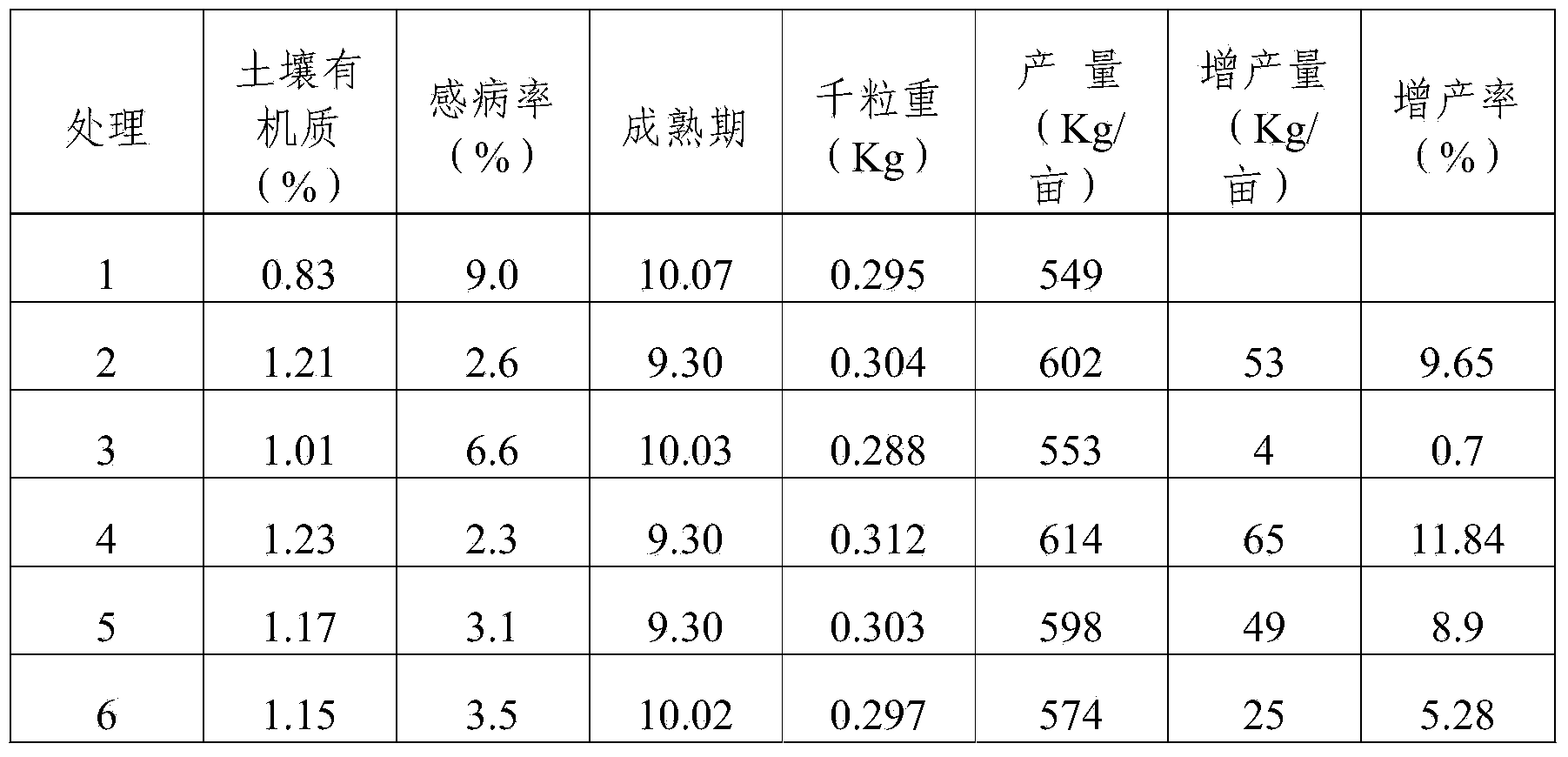

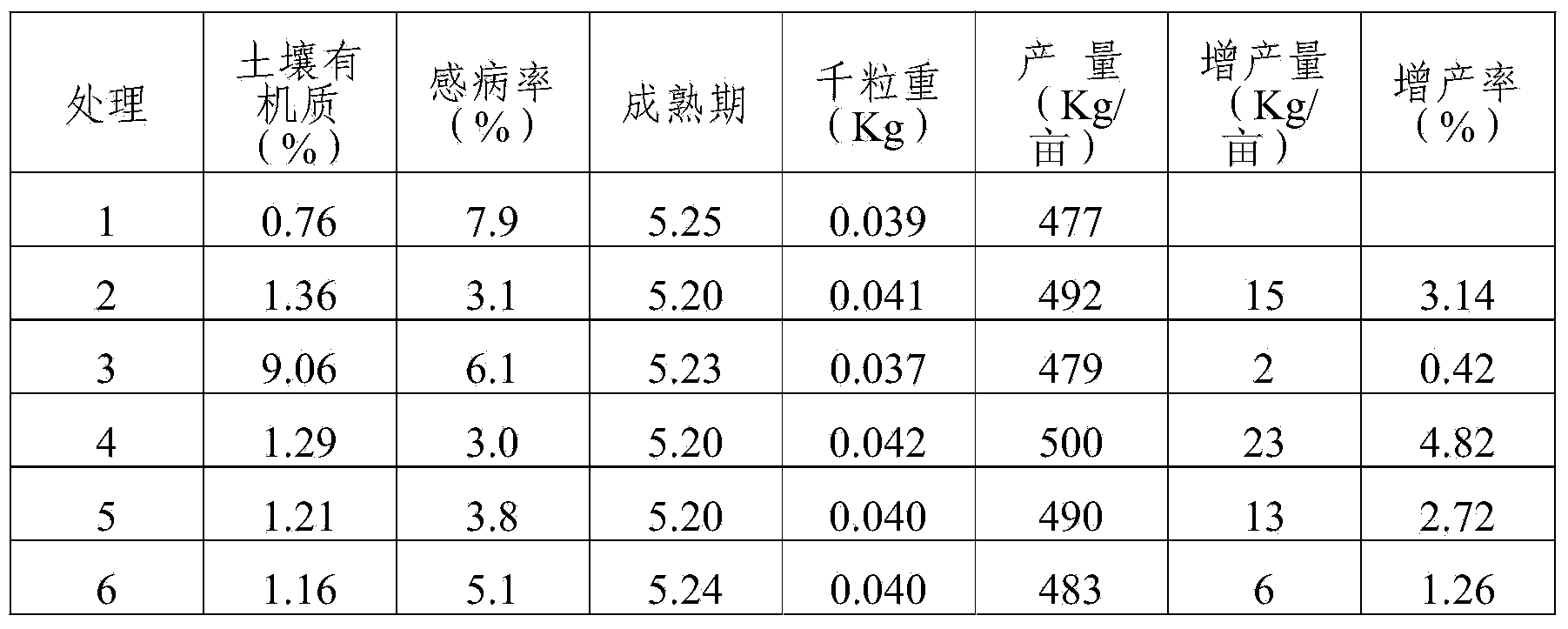

Examples

Embodiment 1

[0037] The concrete composition of biological organic fertilizer described in the present embodiment is as follows:

[0038] Organic fertilizer: 35g of fully decomposed mushroom dregs;

[0039] Inorganic fertilizer: urea 17g, potassium sulfate 16g, diammonium phosphate 2g, superphosphate 10g;

[0040] Polysaccharide additives: amino acid 6g;

[0041] Filler: diatomaceous earth 5g;

[0042] Humic acid: 4g;

[0043] Rot-promoting microbial agent: make sure that each gram of bio-organic fertilizer contains no less than 11.9 billion cfu of decay-promoting microbial strains.

[0044] Among them, each gram of the bio-organic fertilizer includes 3.4 billion cfu of yeast, 1.7 billion cfu of lactic acid bacteria, 1.7 billion cfu of Bacillus megaterium, 1.7 billion cfu of Bacillus jelly-like, 1.7 billion cfu of Bacillus subtilis, and 17 billion cfu of Clostridium pasteurianus billion cfu.

[0045] The bacterial agents used in the preparation of rot-promoting microbial bacterial age...

Embodiment 2

[0052] The concrete composition of biological organic fertilizer described in the present embodiment is as follows:

[0053] Organic fertilizer: 35g of fully decomposed mushroom dregs;

[0054] Inorganic fertilizer: urea 17g, potassium sulfate 16g, diammonium phosphate 2g, superphosphate 10g;

[0055] Polysaccharide additives: amino acid 6g;

[0056] Filler: diatomaceous earth 5g;

[0057] Humic acid: 4g;

[0058] Rot-promoting microbial bacterial agent: make sure that each gram of the bio-organic fertilizer contains no less than 12 billion cfu of decay-promoting microbial strains.

[0059] Wherein, each gram of the bio-organic fertilizer includes 2.4 billion cfu of lactic acid bacteria, 2.4 billion cfu of Bacillus megaterium, 2.4 billion cfu of Bacillus jelly-like, 2.4 billion cfu of Bacillus subtilis, and 2.4 billion cfu of Clostridium pasteuriani.

[0060] The preparation of the putrefaction-promoting microbial bacterial agent adopts conventional technical means in the ...

Embodiment 3

[0063] The concrete composition of biological organic fertilizer described in the present embodiment is as follows:

[0064] Organic fertilizer: 35g of fully decomposed mushroom dregs;

[0065] Inorganic fertilizer: urea 17g, potassium sulfate 16g, diammonium phosphate 2g, superphosphate 10g;

[0066] Polysaccharide additive: chitosan 6g;

[0067] Filler: diatomaceous earth 5g;

[0068] Humic acid: 4g;

[0069] Rot-promoting microbial bacterial agent: make sure that each gram of the bio-organic fertilizer contains no less than 11.9 billion cfu of decay-promoting microbial strains.

[0070] Among them, each gram of the bio-organic fertilizer includes 3.4 billion cfu of yeast, 1.7 billion cfu of lactic acid bacteria, 1.7 billion cfu of Bacillus megaterium, 1.7 billion cfu of Bacillus jelly-like, 1.7 billion cfu of Bacillus subtilis, and 17 billion cfu of Clostridium pasteurianus billion cfu.

[0071] The preparation of the putrefaction-promoting microbial bacterial agent ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com