Method for extracting chlorogenic acid and neochlorogenic acid from bunge pricklyash leaves

A technology of new chlorogenic acid and chlorogenic acid, which is applied to the preparation of carboxylic acid esters, chemical instruments and methods, and the preparation of organic compounds, etc., can solve the problems of unseen preparation of chlorogenic acid and new chlorogenic acid, and achieve convenient operation , The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Grind 10 g of dried Zanthoxylum bungeanum leaves, with an average particle size of 600 μm, then use 300 mL of methanol with a concentration of 80 wt % as an extractant, shake at room temperature for 36 hours, separate the supernatant, and concentrate and dry the supernatant to obtain methanol extract ;

[0040](2) Disperse the above-mentioned methanol extract in 90ml distilled water, the ratio of solid to liquid is 1g: 30mL, then use 180mL ethyl acetate to shake and extract twice, collect the aqueous phase extract, concentrate and dry, and obtain 2.58g of dried sample, the yield 25.8%;

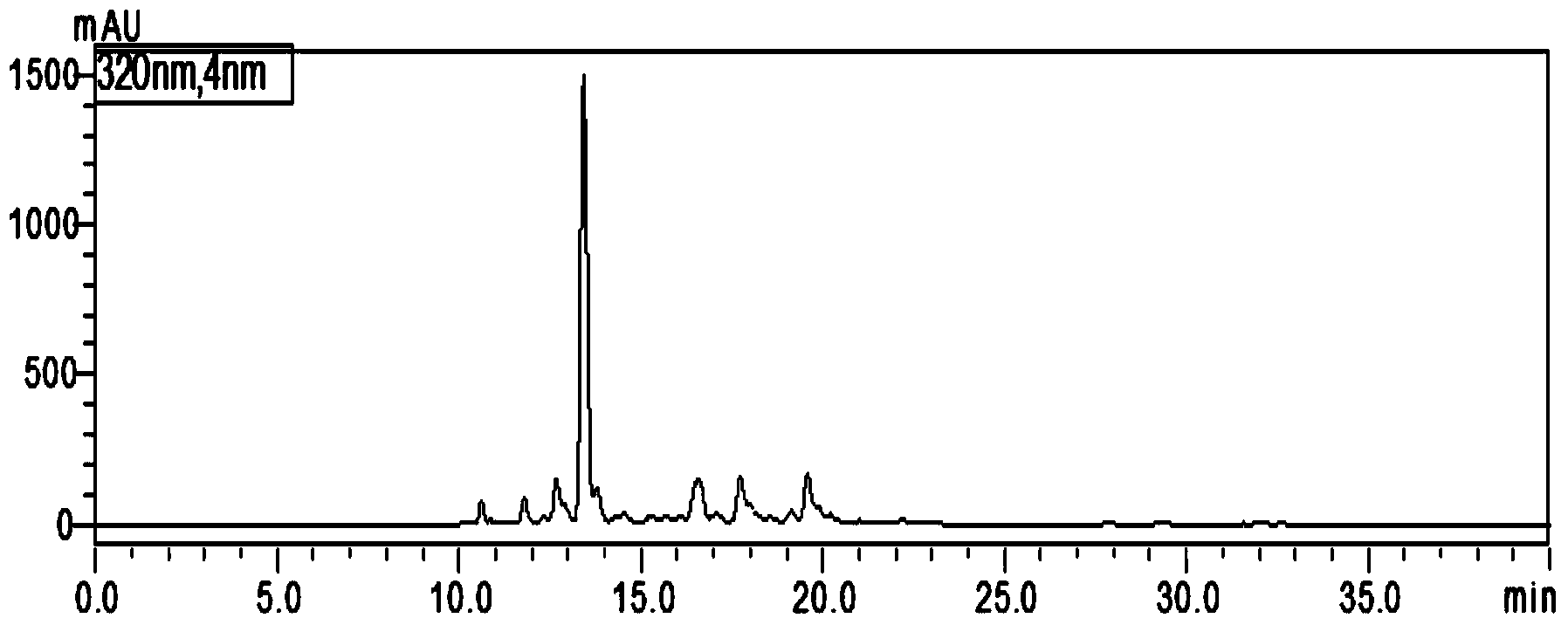

[0041] (3) Take 1 g of the above-mentioned dried sample, dissolve it in 10 mL of distilled water, put it on a reversed-phase resin SciBioChem MCI-GEL chromatography column, the filler height is 20 cm, and the column diameter is 3.2 cm, and it is eluted with methanol-water gradient, and the concentration is 0 wt%. , 10wt%, 20wt%, 30wt%, 40wt%, 50wt% methanol, the elution flow rate i...

Embodiment 2

[0046] (1) Grind 10 g of dried Zanthoxylum bungeanum leaves, with an average particle size of 500 μm, then use 200 mL of methanol with a concentration of 70 wt % as an extractant, shake at room temperature for 30 h, separate the supernatant, and concentrate and dry the supernatant to obtain methanol extract ;

[0047] (2) Disperse the above-mentioned methanol extract in 50ml of distilled water, the ratio of solid to liquid is 1g: 20mL, then use 100mL of ethyl acetate to shake and extract twice, collect the aqueous phase extract, concentrate and dry, and obtain 2.12g of the dried sample, the yield 21.2%;

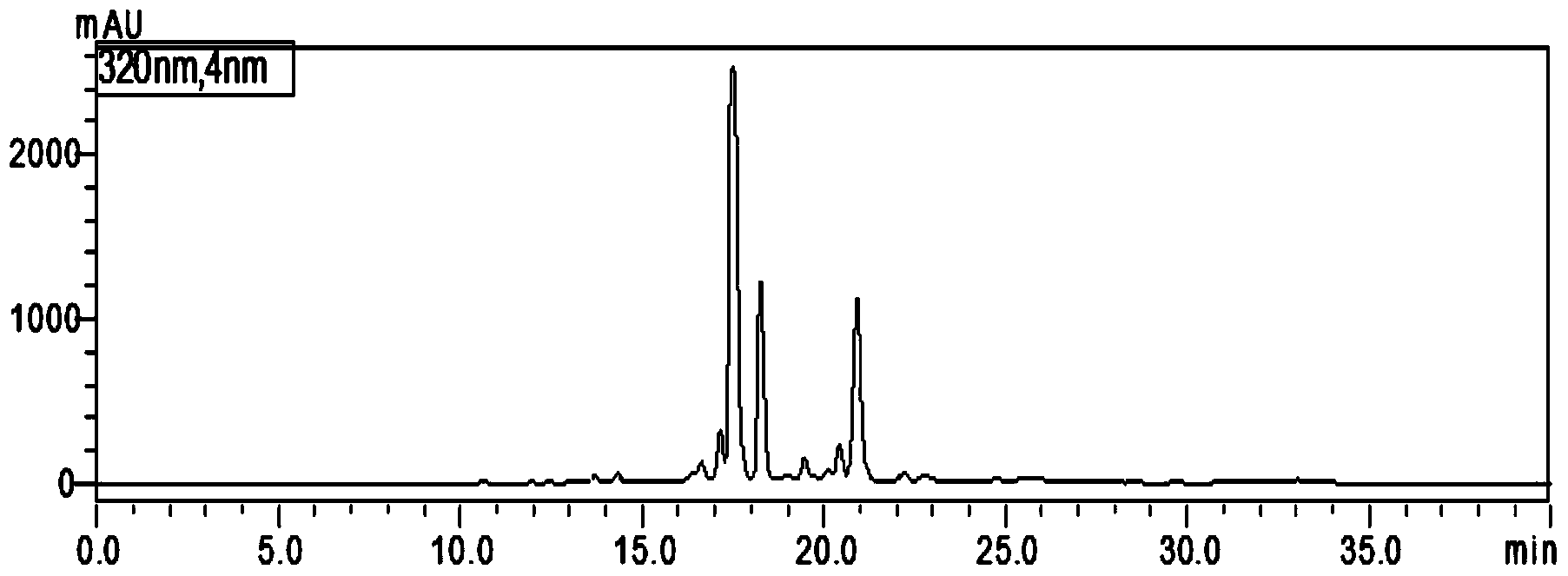

[0048] (3) Take 1 g of the above-mentioned dried sample, dissolve it in 10 mL of distilled water, put it on a reversed-phase resin SciBioChem MCI-GEL chromatography column, the filler height is 20 cm, and the column diameter is 3.2 cm, and it is eluted with methanol-water gradient, and the concentration is 0 wt%. , 10wt%, 20wt%, 30wt%, 40wt%, 50wt% methanol, the elution flow...

Embodiment 3

[0053] (1) Grind 10 g of dried Zanthoxylum bungeanum leaves, with an average particle size of 500 μm, then use 100 mL of methanol with a concentration of 60 wt % as an extractant, shake at room temperature for 24 hours, separate the supernatant, and concentrate and dry the supernatant to obtain methanol extract ;

[0054] (2) Disperse the above-mentioned methanol extract in 25ml of distilled water, the ratio of solid to liquid is 1g: 10mL, then shake and extract once with 25mL of ethyl acetate, collect the aqueous phase extract, concentrate and dry, and obtain 2.07g of dried sample, the yield 20.7%;

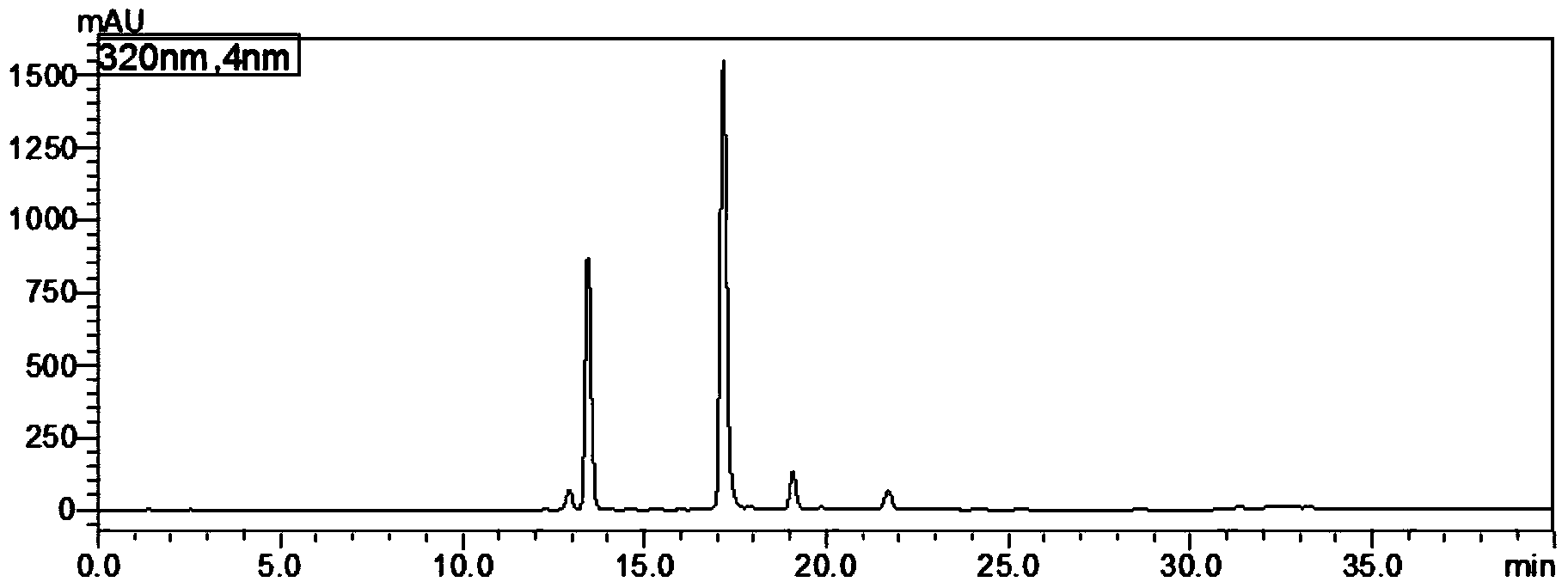

[0055] (3) Take 1 g of the above-mentioned dried sample, dissolve it in 10 mL of distilled water, put it on a reversed-phase resin SciBioChem MCI-GEL chromatography column, the filler height is 20 cm, and the column diameter is 3.2 cm, and it is eluted with methanol-water gradient, and the concentration is 0 wt%. , 10wt%, 20wt%, 30wt%, 40wt%, 50wt% methanol, the elution flow rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com